Electric hoist bridge crane for clean room

A technology for indoor electric hoists and bridge cranes, which is applied in the direction of walking bridge cranes, cranes, load suspension components, etc. The effects of foreign technology constraints, meeting market demand, and structural safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

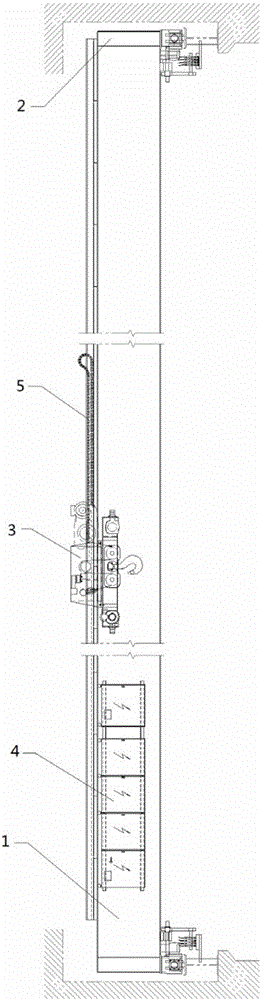

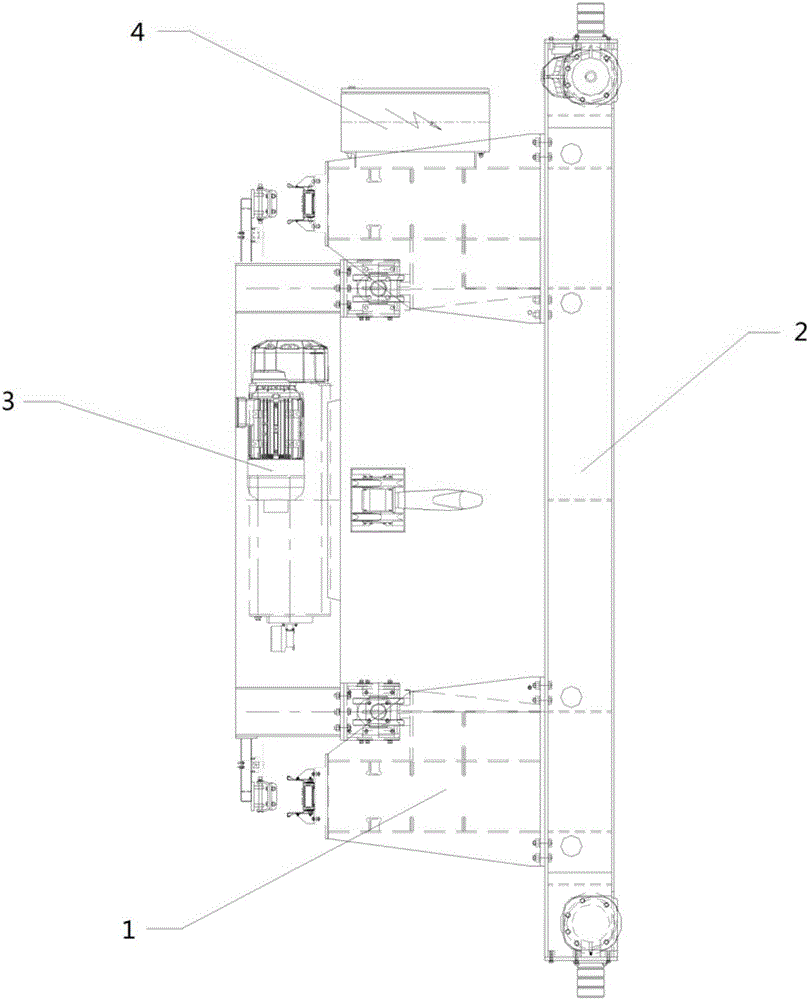

[0016] Example: refer to figure 1 , 2 As shown, an electric hoist bridge crane for a clean room includes two steel structure main girders 1, two large car end girders 2 vertically connected to the two ends of the steel structure main girder 1, and a trolley along the steel structure main girder 1 The electric hoist 3 in the clean room with reciprocating motion on the running track, the electrical control device 4 and the trolley power supply cable, a towline 5 is laid on one of the steel structure main girders 1, and the trolley power supply cable is placed inside the towline 5, and at the same time in the steel structure The surface of main beam 1, cart end beam 2, clean room electric hoist 3 and electrical control device 4 is provided with a layer of inorganic anti-corrosion coating with anti-static powder embedded on the surface. The inorganic anti-corrosion coating is a water-based zinc-chromium coating layer. , not only has strong corrosion resistance, no hydrogen em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com