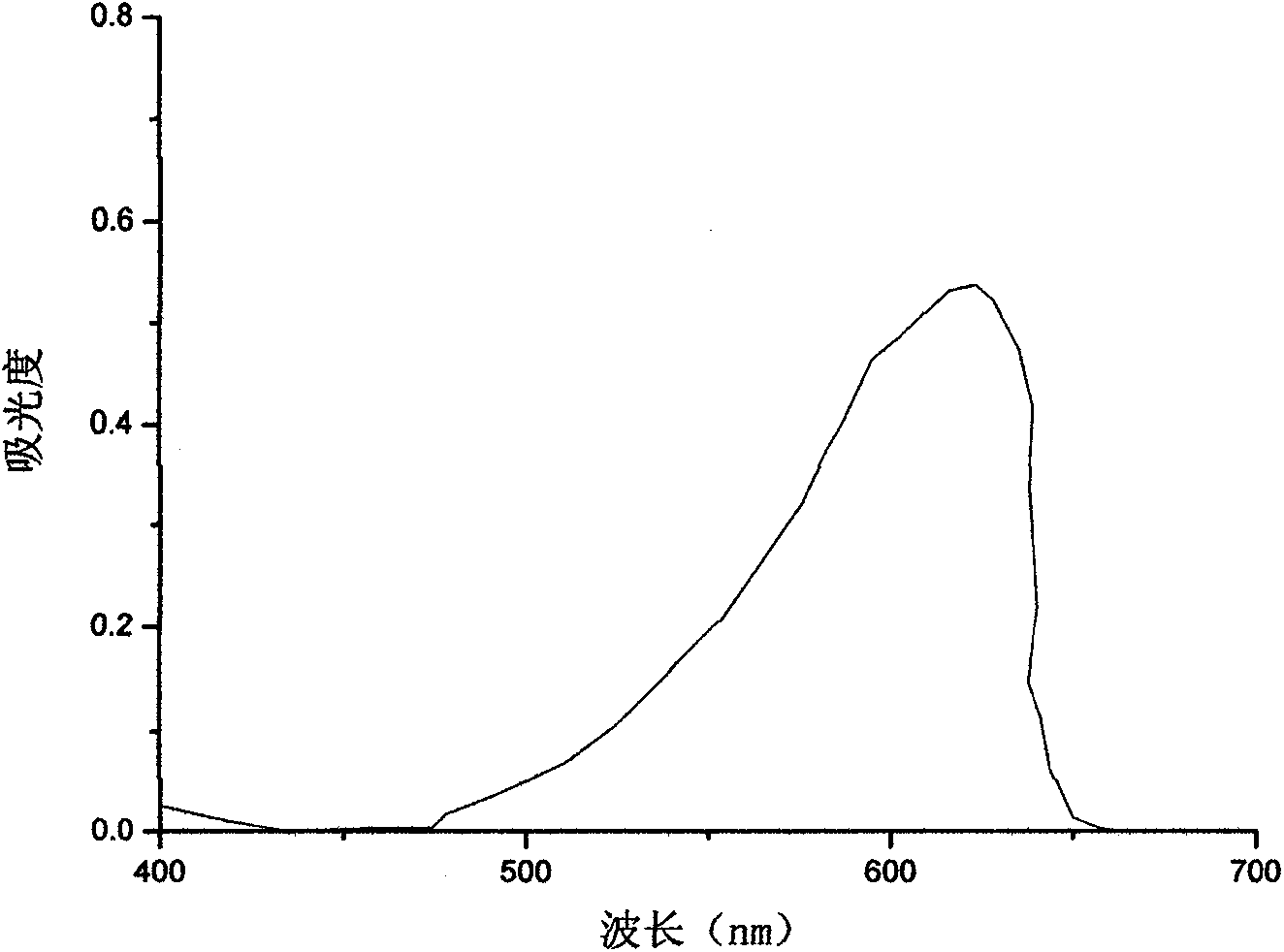

Method of extracting phycocyanin from ionic liquid aqueous two-phase system

A two-phase system, ionic liquid technology, applied in the field of extracting phycocyanin from spirulina, can solve the problems of poor enzyme selectivity, long separation cycle, low separation efficiency, etc., to reduce operating costs and energy consumption, save operation time, the effect of simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) The crushing treatment of Spirulina cells. Take 100g of dry Spirulina platensis algae powder and add 1.5L of 0.05mol / L of K 2 HPO 4 In the aqueous solution, soak for 4 hours at a temperature of 20°C. After soaking, put it into an ultrasonic breaker with an ultrasonic frequency of 40kHz, a power of 1000W, and a temperature of 30°C. Turn on the ultrasonic to break the wall of the Spirulina cells for 15 minutes.

[0022] 2) Ionic liquid two-phase extraction. 225g ionic liquid, 75g K 2 HPO 4 Add to the crude extract of phycocyanin, stir well to make the solid K 2 HPO 4 And the ionic liquid can be quickly dissolved in the crude extract, and effectively form a two-phase system, and the extraction process ends after 90 minutes of extraction. The extraction process is over. The solid is removed by filtration and separation, the liquid part is left to stand for stratification, and the upper layer is an ionic liquid layer containing phycocyanin.

[0023] 3) Separation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com