Epoxy resin composition

A technology of epoxy resin and composition, applied in the field of epoxy resin composition, can solve the problems of organic solvent volatilization, insufficient heat resistance and mechanical strength, low solid content, etc., and achieve low organic matter volatility, free phenol and volatile The effect of low parts, enhanced heat resistance and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

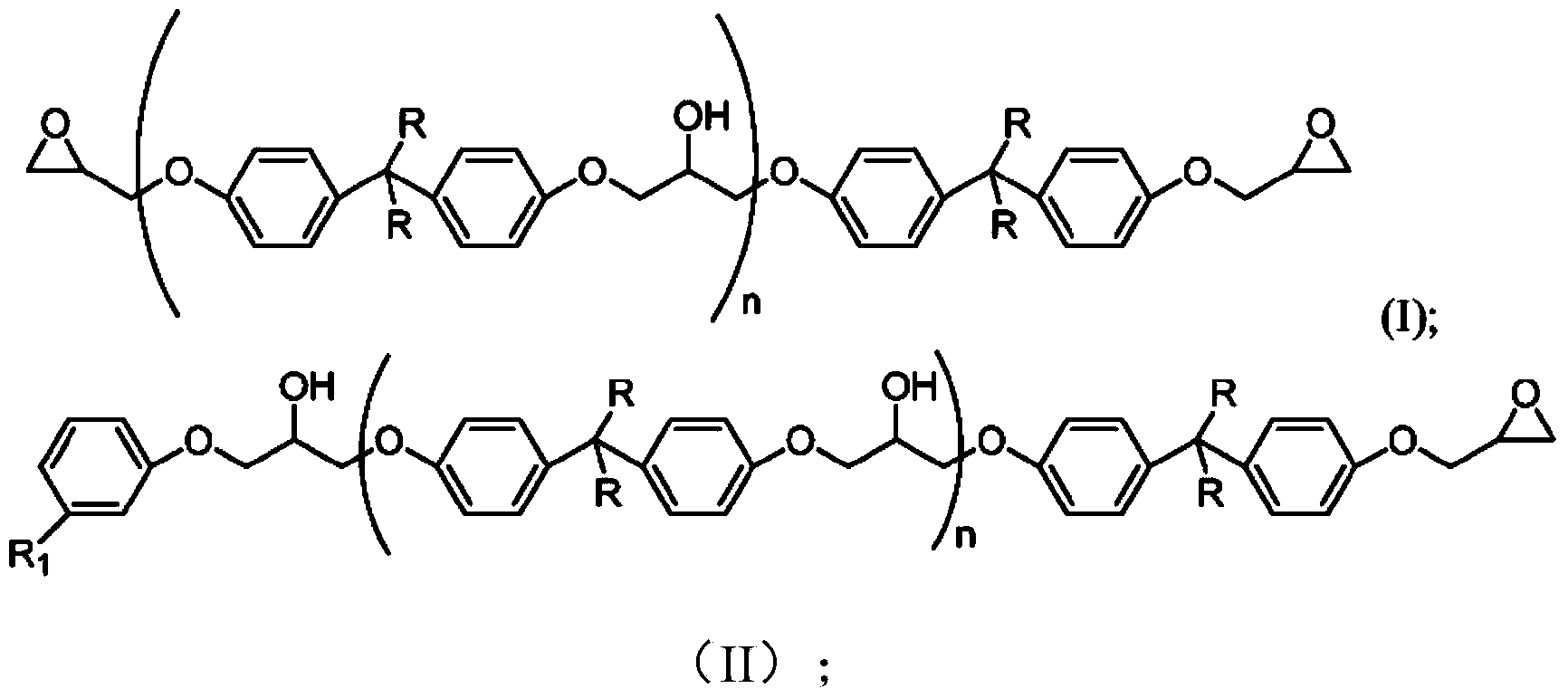

[0031] 80 parts by weight of diglycidyl ether of bisphenol A and 20 parts by weight of cardanol were mixed under a nitrogen atmosphere, then the mixture was heated to 90° C., and 400 ppm of ethyl triphenylphosphine acetate was added as a catalyst. Then the mixture was heated to 170° C. and kept for 3 hours, and epoxy resin A was obtained, which contained 55% by weight of the epoxy resin of the formula (I) and 45% by weight of the epoxy resin of the formula (II).

preparation example 2

[0033] 92 parts by weight of diglycidyl ether of bisphenol A and 8 parts by weight of cardanol were mixed under a nitrogen atmosphere, then the mixture was heated to 90° C., and 200 ppm of ethyl triphenylphosphine acetate was added as a catalyst. Then the mixture was heated to 180° C. and kept for 2 hours, and epoxy resin B was obtained, which contained 81% by weight of the epoxy resin of the formula (I) and 19% by weight of the epoxy resin of the formula (II).

preparation example 3

[0035] 65 parts by weight of diglycidyl ether of bisphenol A and 35 parts by weight of cardanol were mixed under nitrogen atmosphere, then the mixture was heated to 90° C., and 300 ppm of ethyl triphenylphosphine acetate was added as a catalyst. Then the mixture was heated to 180° C. and kept for 3 hours, and epoxy resin C was obtained, which contained 20% by weight of the epoxy resin of the formula (I) and 80% by weight of the epoxy resin of the formula (II).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com