Modified resorcinol formaldehyde resin as well as preparation method and application thereof

A resorcinol formaldehyde resin and resorcinol technology, applied in the field of rubber processing aids, can solve the problems of resorcinol retention, non-renewable, odor residue, etc., achieve low smoke and odor, and excellent aging performance , Excellent tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

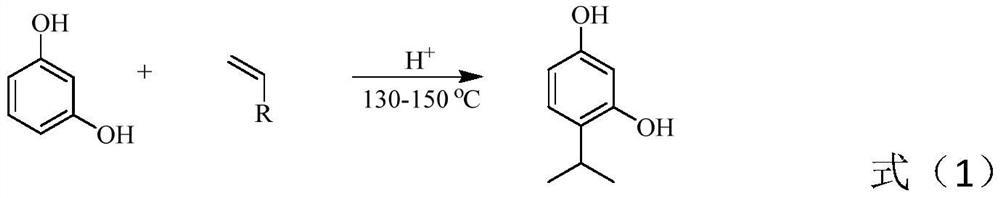

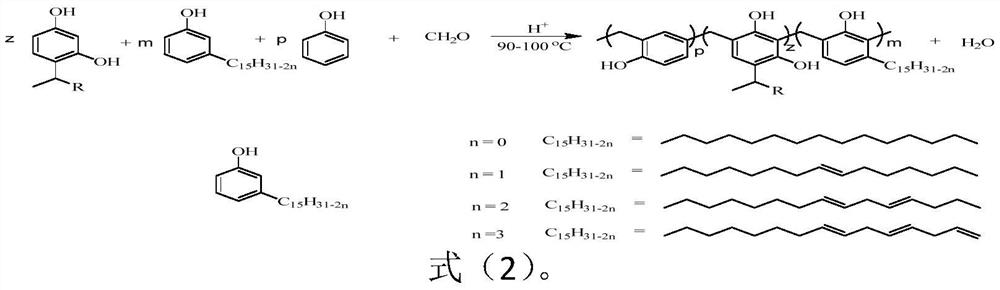

Method used

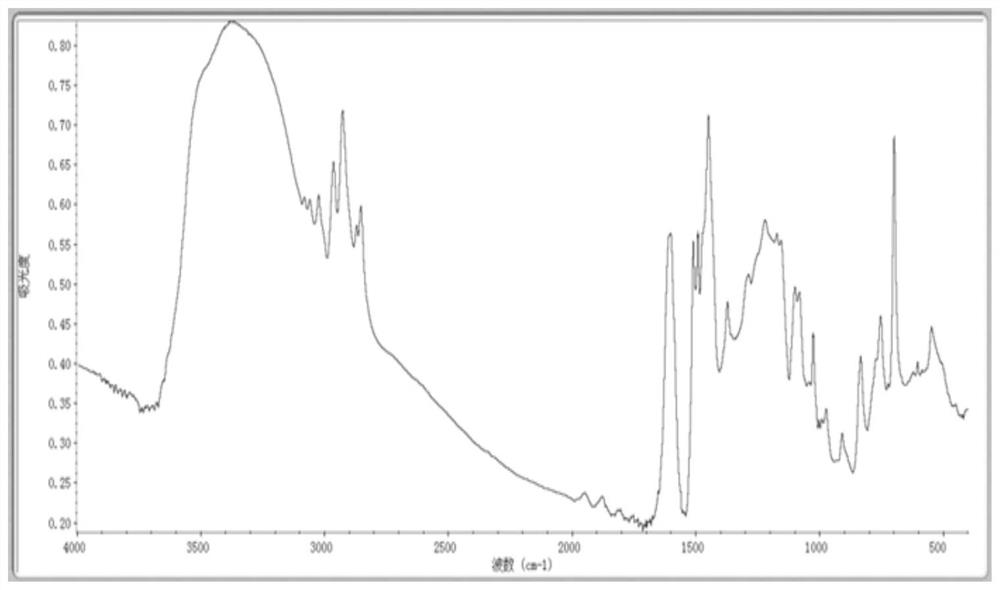

Image

Examples

Embodiment 1

[0044] In the 1L four-neck round bottom flask equipped with stirring, temperature control, reflux condenser and constant pressure dropping funnel, add resorcinol 110g (1mol), add catalyst p-toluenesulfonic acid 0.8g (0.8%), heat up To 130°C, add 72.8g (0.7mol) of styrene dropwise at 130°C, keep the temperature for 90min after the dropwise addition, add 44g of cardanol, 66g of phenol and stir for 1h, cool down to 100°C, then add dropwise 81g of 37% formaldehyde ( 0.97mol), heated up and distilled at atmospheric pressure to 160°C, distilled under reduced pressure at -0.08mpa for 60min, blown phenol at 0.01mpa, blown phenol to 280g of effluent quality, obtained 288g of 95°C modified resorcinol formaldehyde at atmospheric pressure resin.

[0045] The amount of raw materials added for each component in Examples 2-5 is shown in Table 1 and prepared according to the method of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com