Sepiolite-loaded soluble rubber powder modified asphalt and preparation method thereof

A technology for modifying asphalt and sepiolite powder, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of excessive viscosity, easy aging, and poor production environmental protection, and achieves improved stability, excellent adsorption performance, improved The effect of excessive viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

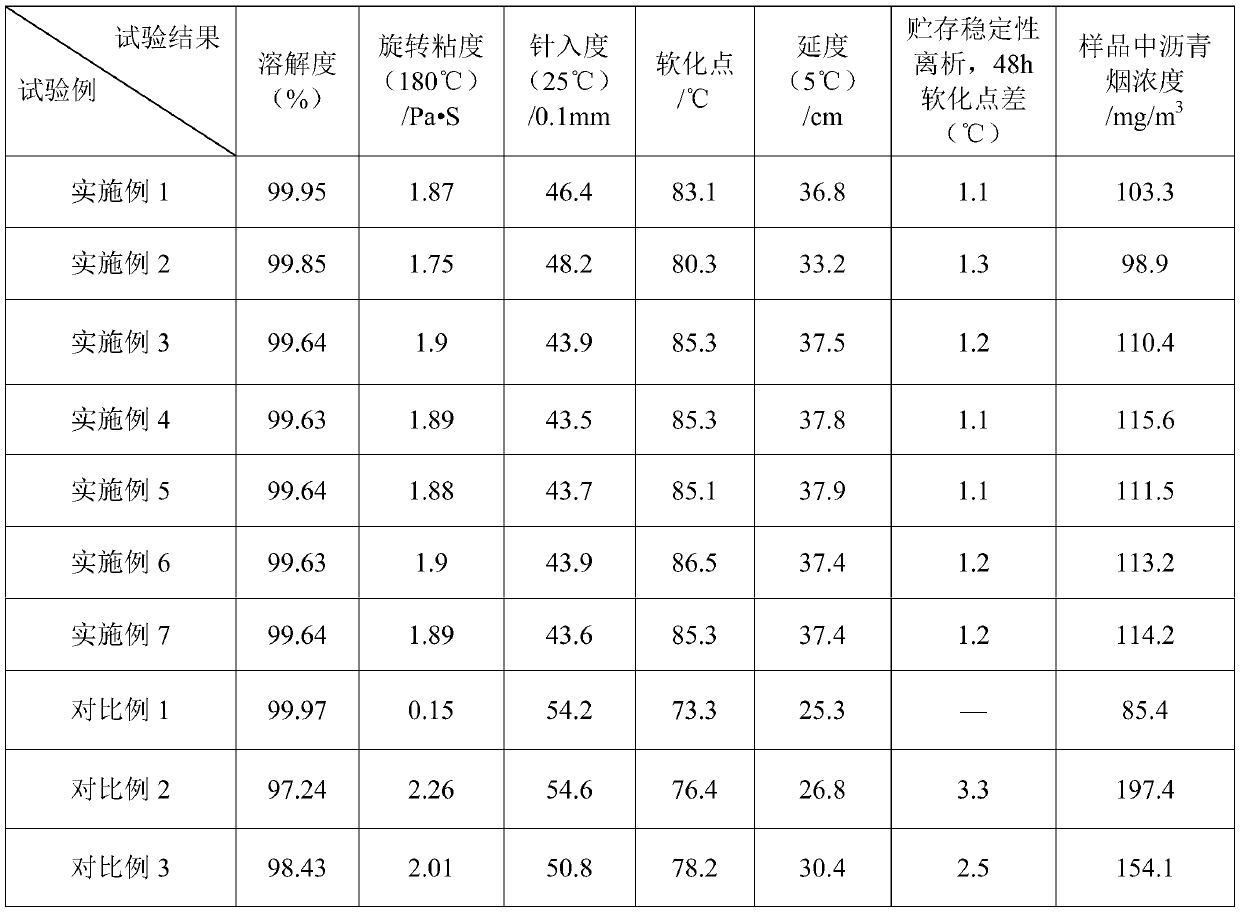

Embodiment 1

[0051] In this example, sepiolite-loaded soluble rubber powder modified asphalt is prepared from the following raw materials in parts by weight:

[0052] 71 parts of petroleum asphalt, 12 parts of 100 mesh rubber particles, 12 parts of sepiolite powder, 0.1 part of stabilizer dibenzothiazole disulfide, 5 parts of rubber oil, crosslinking agent 4,4'-diamino-3,3'- 0.1 part of dichlorodiphenylmethane; wherein the petroleum asphalt is straight-run asphalt, the sum of saturated and aromatic content in its composition should be between 55%, and the saturated content should be less than 16%.

[0053] Prepare the soluble rubber powder modified asphalt with high storage stability as follows:

[0054] (1) Put the sepiolite powder in an oven at 150°C for 3 hours to reach a dry state, and set aside;

[0055] (2) Put 100-mesh rubber granules in a high-speed shearing machine, shear at a speed of 4000 rpm for 60 minutes, then mix the sheared rubber powder with sepiolite powder, add rubber o...

Embodiment 2

[0059] The sepiolite-loaded soluble rubber powder modified asphalt is prepared from the following raw materials in parts by weight: 72 parts of petroleum asphalt, 10 parts of 100 mesh rubber particles, 12 parts of sepiolite powder, and 0.1 part of stabilizer dibenzothiazole disulfide , 6 parts of rubber oil, 0.1 part of crosslinking agent 4,4'-diamino-3,3'-dichlorodiphenylmethane; among them, petroleum asphalt is straight-run asphalt, the sum of saturated and aromatic content in its composition It should be between 55%, and the saturated content should be less than 16%.

[0060] The preparation method of the sepiolite-loaded soluble rubber powder modified asphalt is the same as that in Example 1.

Embodiment 3

[0062] The sepiolite-loaded soluble rubber powder modified asphalt is prepared from the following raw materials in parts by weight: 68 parts of petroleum asphalt, 15 parts of 100 mesh rubber particles, 12 parts of sepiolite powder, and 0.1 part of stabilizer dibenzothiazole disulfide , 5 parts of rubber oil, 0.1 part of crosslinking agent 4,4'-diamino-3,3'-dichlorodiphenylmethane; among them, petroleum asphalt is straight-run asphalt, the sum of saturated and aromatic content in its composition It should be between 55%, and the saturated content should be less than 16%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com