Cage-shaped oligomeric silsesquioxane modified flame-retardant vinyl ester resin composition and preparation method and application thereof

A technology of vinyl ester resin and sesquioxane, which is applied in the field of flame retardancy, can solve the problems of poor flame retardancy and large amount of reinforcing fiber, and achieve the effect of simple preparation method and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0086] The present invention also provides the preparation method of the clathrate oligomeric silsesquioxane modified flame retardant vinyl ester resin composition described in the above technical scheme, comprising the following steps:

[0087] Mix the vinyl ester resin, cage POSS and accelerator by weight fraction to obtain a vinyl ester resin system;

[0088] The vinyl ester resin system is mixed with a curing agent and cured to obtain a clathrate oligomeric silsesquioxane modified flame retardant vinyl ester resin composition.

[0089] In the present invention, the vinyl ester resin, cage POSS and accelerator are mixed according to the weight fraction to obtain the vinyl ester resin system. In the present invention, the mixing temperature is preferably 25-100°C.

[0090] After the vinyl ester resin system is obtained, the present invention mixes the vinyl ester resin system with a curing agent and then cures to obtain a cage-shaped oligomeric silsesquioxane modified flame...

Embodiment 1

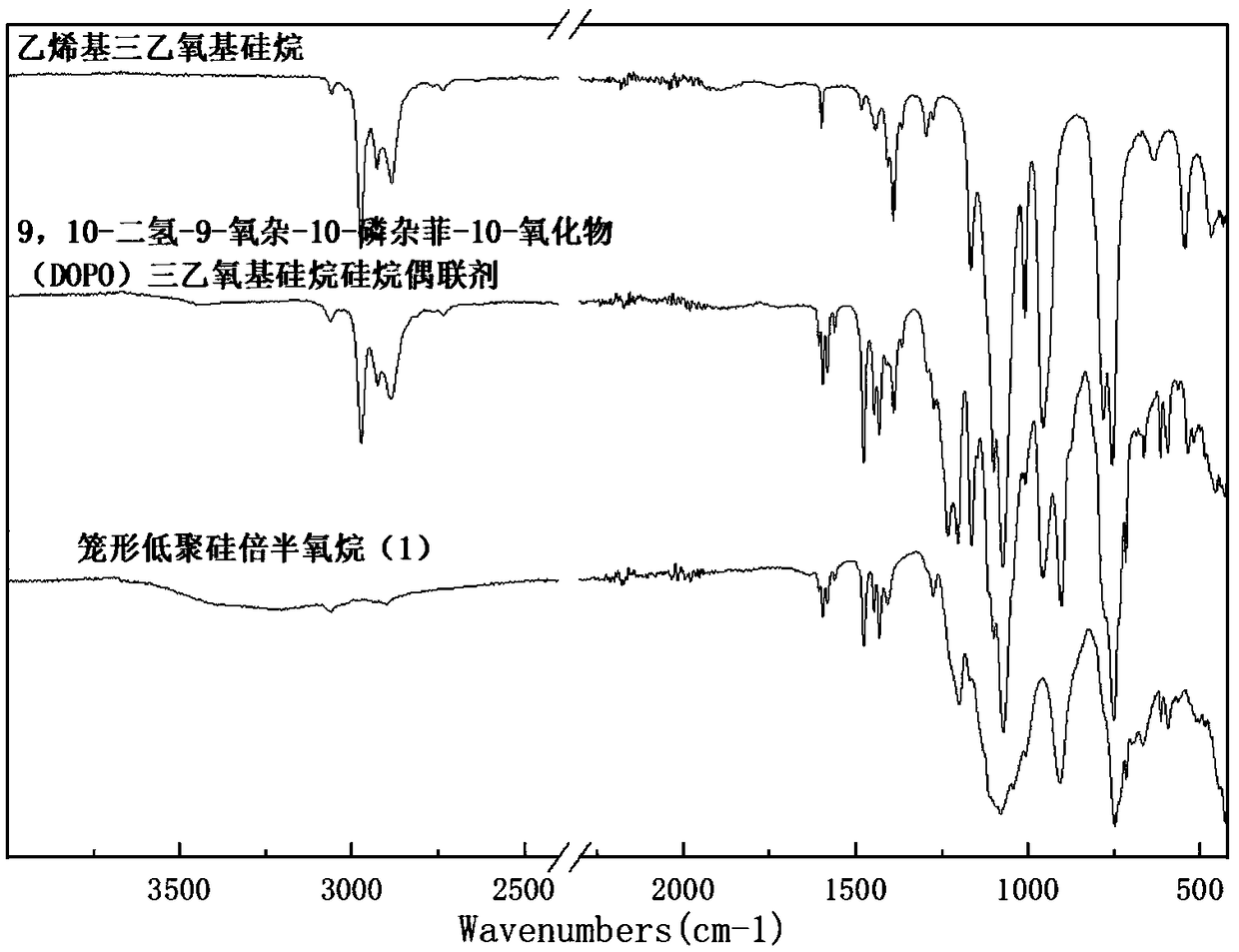

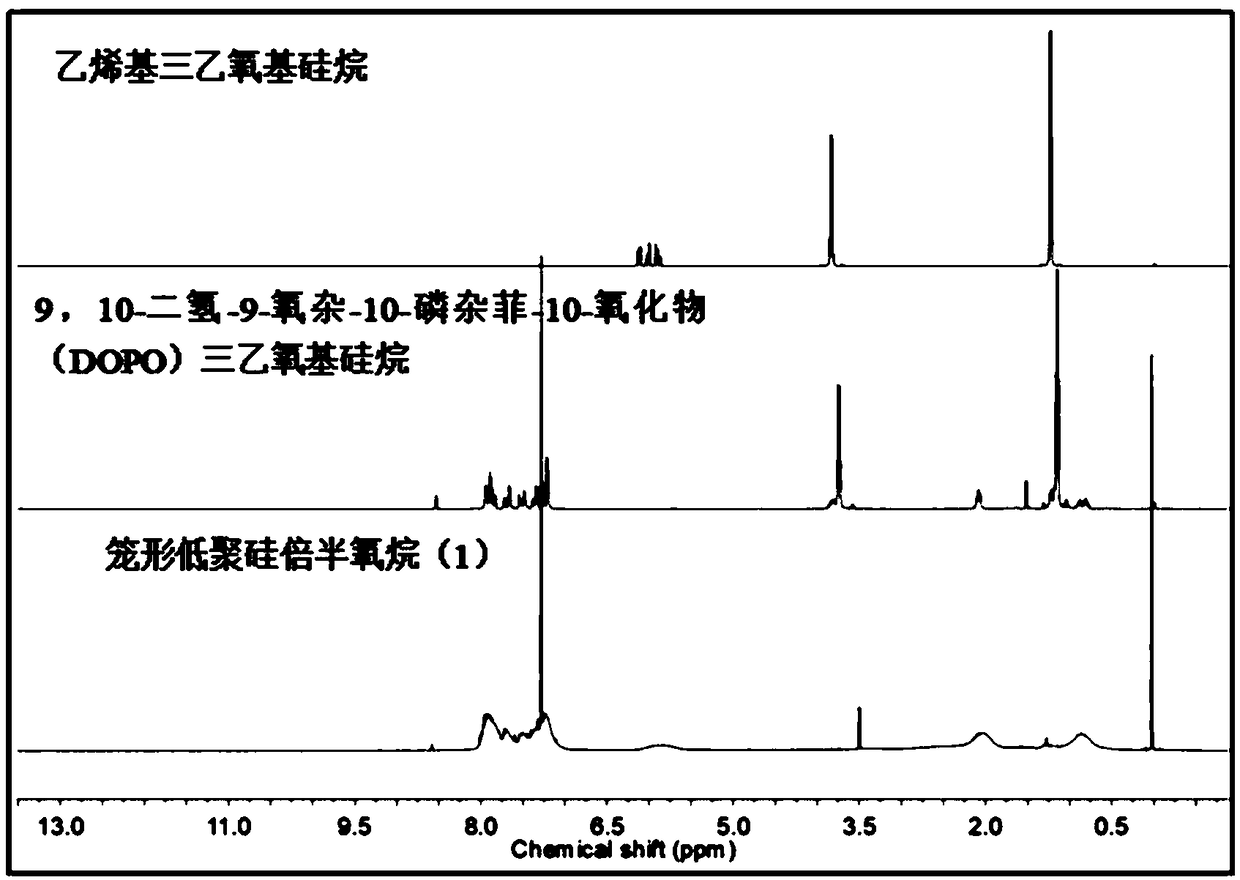

[0097] Preparation of caged POSS

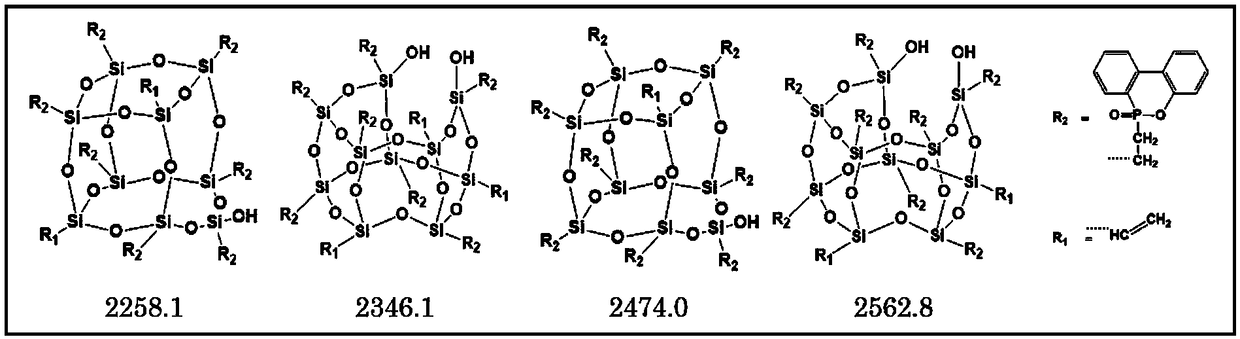

[0098] Under an air atmosphere, mix 28.42 g of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide triethoxysilane, 2.38 g of vinyltriethoxysilane and 250 mL of methanol And fully stirred, 3mL of concentrated hydrochloric acid (mass fraction: 36.5%) was added dropwise, after the system was uniformly mixed, the temperature was raised to 70°C, 4mL of deionized water was added dropwise, and reacted for 24h. After the reaction, the product was slowly dropped into deionized water to precipitate according to the volume ratio of 1:11, filtered, washed and dried to obtain a white powder, which was dissolved in a sufficient amount of chloroform, and then mixed according to the volume ratio of 1 : 5 the mixed system is added in normal hexane, filter after sufficient precipitation, wash, dry, obtain the clathrate oligomeric silsesquioxane (cage POSS) that has phosphorus and double bond group simultaneously, denote as cage Oligomeric silsesquioxanes (1)....

Embodiment 2

[0109] Cage POSS preparation

[0110] Under an air atmosphere, mix 28.42 g of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide triethoxysilane, 13.3 g of vinyltriethoxysilane and 300 mL of methanol And fully stirred, 3mL of concentrated hydrochloric acid (mass fraction: 36.5%) was added dropwise, after the system was uniformly mixed, the temperature was raised to 65°C, 6mL of deionized water was added dropwise, and reacted for 20h. After the reaction, the product was slowly dropped into deionized water for precipitation according to the volume ratio of 1:10, filtered, washed and dried to obtain a white powder, which was dissolved in a sufficient amount of chloroform, and then mixed according to the volume ratio of 1 : 6 mixed system is joined in normal hexane, filter after sufficient precipitation, wash, dry, obtain the clathrate oligomeric silsesquioxane (cage POSS) that has phosphorus and double bond group simultaneously, denote as cage Oligomeric silsesquioxanes (2). At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com