Silane coupling agent modified lithium silicate base coating and preparation method thereof

A silane coupling agent, lithium silicate technology, applied in the direction of alkali metal silicate coatings, coatings, etc., can solve the problem that the coating film of lithium silicate based coatings is hard and brittle, prone to cracks, and the decorative effect is not ideal and other problems, to achieve the effect of low energy consumption and overcoming hard and brittle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

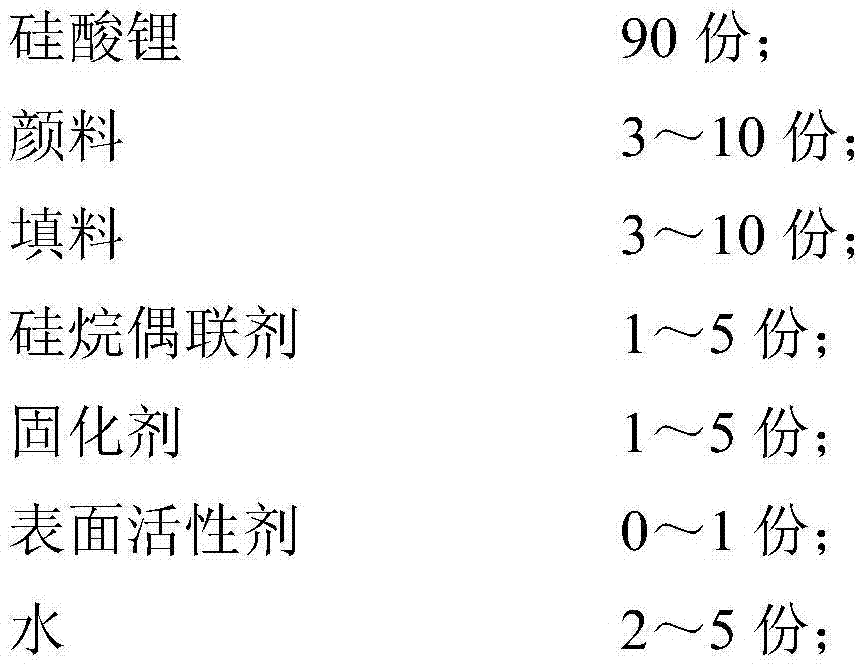

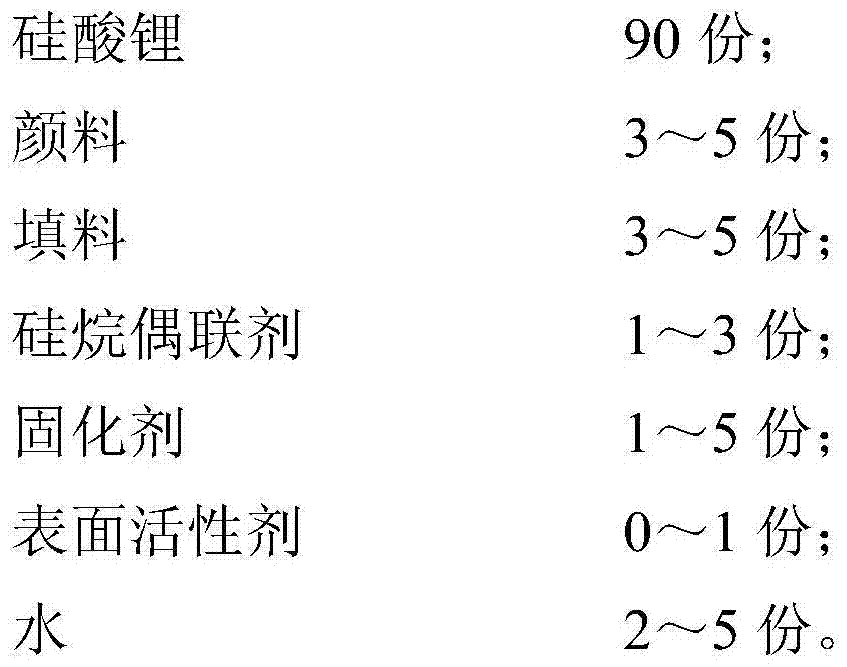

Method used

Image

Examples

Embodiment 1

[0038] paint preparation

[0039] Grind the quartz powder and chromium oxide in a ball mill respectively, and screen out the quartz powder and chromium oxide with a particle size of ≤10um, mix 5 parts of quartz powder with a particle size of ≤10um and 5 parts of chromium oxide with a particle size of ≤10um, and then add 5 parts Mix and stir water and 90 parts of lithium silicate aqueous solution with a mass percentage of 22.5% and a modulus of 4.8, and measure with a fineness measuring instrument. The degree of dispersion in the mixture reaches below 10um, and the insoluble matter is filtered off. Slowly add 3 parts of γ-aminopropyltriethoxysilane (KH550), 3 parts of aluminum phosphate and 1 part of zinc oxide during the stirring process, and stir evenly to obtain the silane coupling agent modified lithium silicate coating.

[0040] Coating flexibility

[0041] The impact strength of the paint is 30kg·cm. The flexibility and impact resistance of the paint are related. The high ...

Embodiment 2

[0045] Grind mica and titanium oxide in a ball mill respectively, and screen out dimica and titanium oxide with a particle size of ≤10um, mix 5 parts of mica with a particle size of ≤10um and 10 parts of titanium oxide with a particle size of ≤10um, and then add 5 parts of water and 90 parts of lithium silicate aqueous solution with a mass percentage of 22.5% and a modulus of 4.8 were mixed and stirred, and measured with a fineness measuring instrument. The degree of dispersion in the mixture reached below 10um, and the insoluble matter was filtered off. Slowly add 1 part of γ-aminopropyltriethoxysilane (kh550), 3 parts of aluminum phosphate and 0.5 part of zinc oxide during stirring, and stir evenly to obtain the desired coating.

[0046] Coating flexibility

[0047] The impact strength of the paint is 40kg·cm. The flexibility and impact resistance of the paint are related. The high impact strength of the paint can reflect the good flexibility of the paint.

[0048] Other Pr...

Embodiment 3

[0051] paint preparation

[0052] Grind quartz powder and iron oxide in a ball mill respectively, and screen out quartz powder and chromium oxide with a particle size of ≤10um, mix 5 parts of quartz powder with a particle size of ≤10um and 5 parts of iron oxide with a particle size of ≤10um, and then add 5 parts Mix and stir water and 90 parts of lithium silicate aqueous solution with a mass percentage of 22.5% and a modulus of 4.8, and measure with a fineness measuring instrument. The degree of dispersion in the mixture reaches below 10um, and the insoluble matter is filtered off. Slowly add 1 part of γ-aminopropyltriethoxysilane (KH550) and 1 part of aluminum phosphate during stirring, and stir evenly to obtain the required coating.

[0053] Coating flexibility

[0054] The impact strength of the paint is 45kg·cm. The flexibility and impact resistance of the paint are related. The high impact strength of the paint can reflect the good flexibility of the paint.

[0055] Oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com