High-water-solubility and high-temperature-resistant Mannich base corrosion inhibitor intermediate and preparation method thereof

A Mannich base and high temperature resistant technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem that the Mannich base is easily decomposed at high temperature, the antimony trichloride is highly corrosive, and the production of corrosion inhibitors is inconvenient. and other problems, to achieve the effect of low preparation cost, solving the problem of strong acid corrosion, and inhibiting the acidification corrosion of high temperature hydrochloric acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

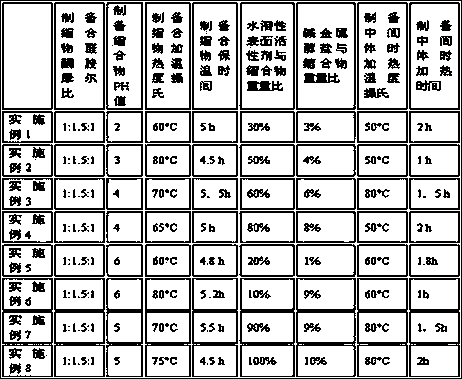

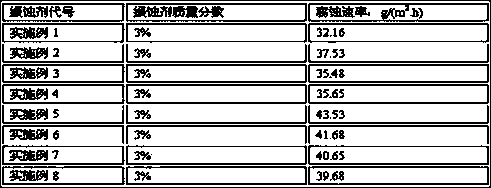

Embodiment 1

[0028] Add organic amines, aldehydes, and ketones into the reactor at a molar ratio of 1:1.5:1, then add ethylene glycol and mix well, adjust the pH value of the solution to 2.0, then heat up to 60°C, and keep the temperature for 5 hours to obtain aldehyde Ketoamine Condensate.

[0029] Based on the total weight of the aldehyde, ketone, and amine condensates, a water-soluble surfactant accounting for 30% of the total weight of the aldehyde, ketone and amine condensates, and an alkali metal that accounts for 3% of the total weight of the aldehyde, ketone and amine condensates are added to the aldehyde, ketone and amine condensates Alcoholate, the above solution was stirred evenly, and the temperature was raised to 50° C., and reacted for 2 hours to obtain a highly water-soluble, high-temperature-resistant Mannich base corrosion inhibitor intermediate.

[0030] Above-mentioned reactor, also can adopt three-necked flask in a small amount of use, hereinafter described with this. ...

Embodiment 2

[0035] Add organic amines, aldehydes, and ketones to the reactor at a molar ratio of 1: 1.5:1, then add ethylene glycol and mix well, adjust the pH value of the solution to 3.0, then heat up to 80°C, and keep the temperature for 4.5 hours to obtain aldehyde Ketoamine Condensate.

[0036] Based on the total weight of the aldehyde, ketone, and amine condensates, a water-soluble surfactant accounting for 50% of the total weight of the aldehyde, ketone and amine condensates, and an alkali metal that accounts for 4% of the total weight of the aldehyde, ketone and amine condensates are added to the aldehyde, ketone and amine condensates. Alcoholate, the above solution is stirred evenly, and the temperature is raised to 50°C, and reacted for 1 hour to obtain a highly water-soluble, high-temperature-resistant Mannich base corrosion inhibitor intermediate.

Embodiment 3

[0038] Add organic amines, aldehydes, and ketones into the reactor at a molar ratio of 1: 1.5:1, then add ethylene glycol and mix well, adjust the pH value of the solution to 4.0, then heat up to 70°C, and keep the temperature for 5.5 hours to obtain aldehyde Ketoamine Condensate.

[0039] Based on the total weight of the aldehyde, ketone, and amine condensates, a water-soluble surfactant accounting for 60% of the total weight of the aldehyde, ketone and amine condensates, and an alkali metal that accounts for 6% of the total weight of the aldehyde, ketone and amine condensates are added to the aldehyde, ketone and amine condensates. Alcoholate, the above solution was stirred evenly, and the temperature was raised to 80° C., and reacted for 1.5 hours to obtain a highly water-soluble, high-temperature-resistant Mannich base corrosion inhibitor intermediate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com