A Method for Large Plastic Deformation of High Volume Fraction Particle Reinforced Metal Matrix Composites

A high volume fraction, large plastic deformation technology, applied in the field of large plastic deformation of particle reinforced metal matrix composites, can solve the problems of large plastic deformation, poor plasticity and large plastic deformation, etc., achieve a large soft coefficient and improve mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

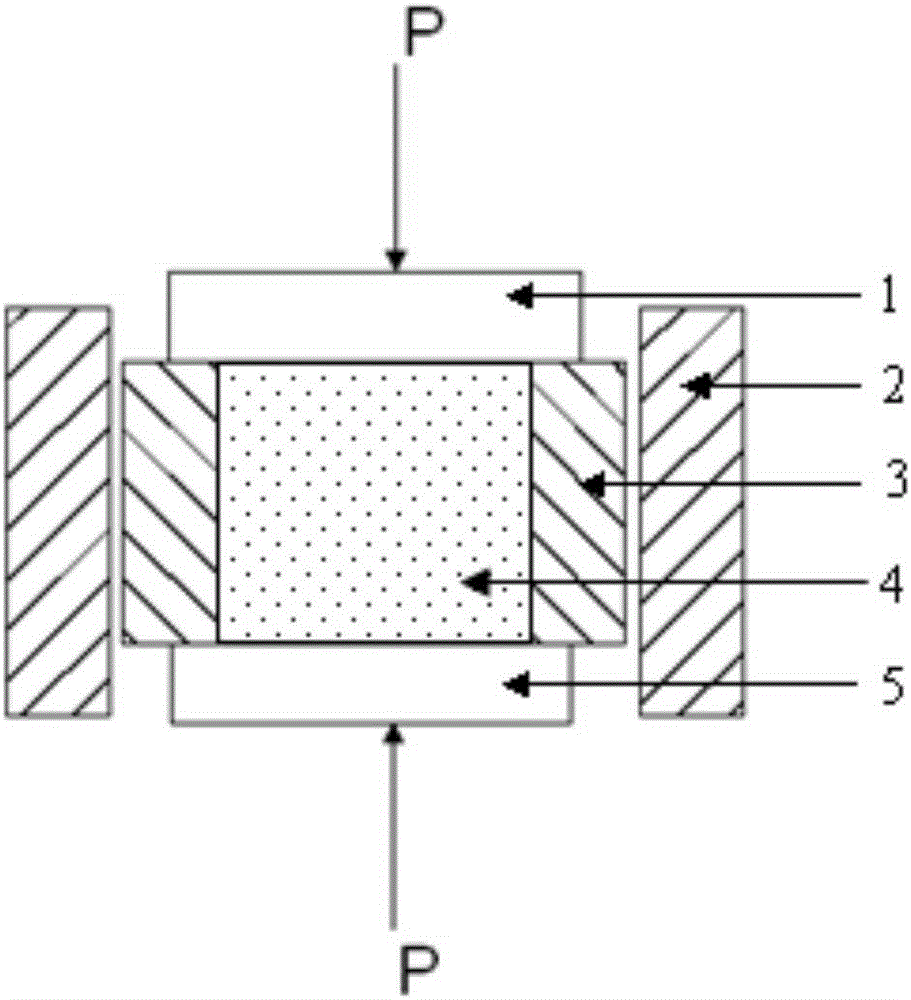

[0028] Specific implementation mode 1: The method for the large plastic deformation of the high volume fraction particle reinforced metal matrix composite material in this implementation mode is carried out according to the following steps:

[0029] 1. Parts and raw material processing: processing cylindrical composite material blanks and metal sheaths;

[0030] 2. Preparation before heating: apply lubricant to the composite material blank, indenter, mold and bag;

[0031] 3. Heating and heat preservation: Preheat the composite material billet and sheath to within plus or minus 100°C of the solidus line of the matrix alloy, and keep it warm for 0.5h to 3h. The heat preservation temperature of the mold and pressure head is at or below the preheating temperature of the composite material billet Within 100°C of the preheating temperature;

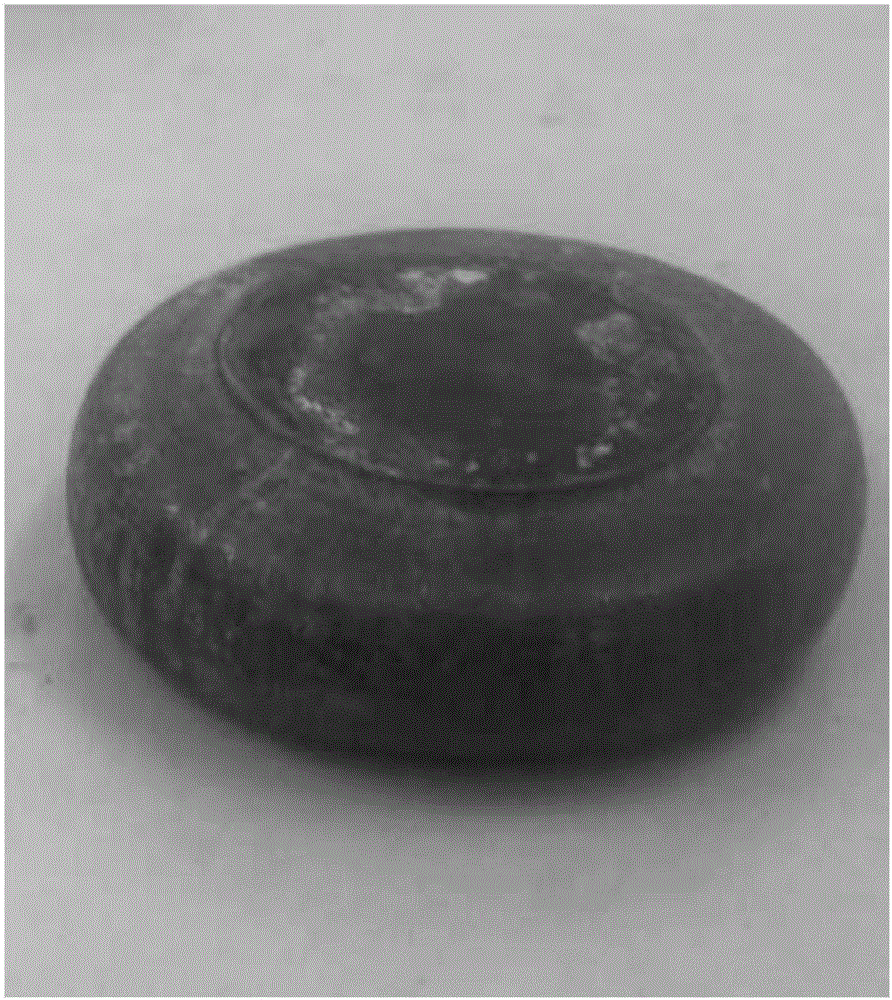

[0032] 4. Pressure deformation: put the preheated composite material blank and sheath in the mold to ensure that the diameter of the indente...

specific Embodiment approach 2

[0041] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the volume fraction of particles in the composite material blank is 30% to 65%, the particles are ceramic particles, and the matrix alloy in the composite material blank is aluminum and its Aluminum alloy or magnesium and its magnesium alloys. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0042] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the particles in the composite material blank are metal oxides, metal carbides, metal nitrides or metal borides. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| deformation temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com