Preparation methods of organic oxime rust transforming agent and aqueous iron rust transforming undercoat

A rust conversion agent and rust conversion technology, which is applied in the coating process of metal materials, etc., can solve the problems of less application, high cost of rusty coatings in the penetrating layer, and difficulty in wide-scale promotion, so as to achieve good coating quality and strong salt resistance Fog penetration ability, the effect of low surface treatment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

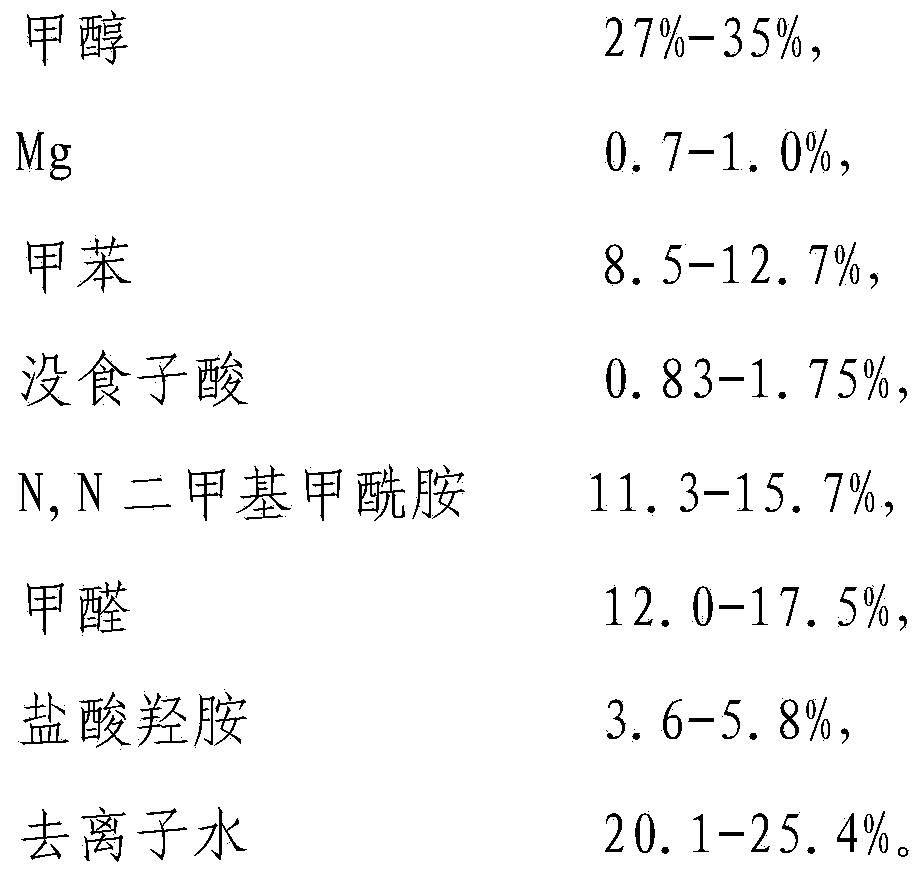

[0050] Synthesis of organic oxime rust conversion agent: Add 32.10g of methanol and 10.00g of toluene to a four-necked flask equipped with a stirring bar, a thermometer, a constant pressure dropping funnel and a condenser tube, and add 1.16g of Mg bars in batches at 65°C for reaction 5h, add 5g of toluene during the period, after the reaction is complete, start to heat up to 70-75°C, use the semi-continuous dropping process to add a mixed solution of 1.12g gallic acid and 17.33gDMF dropwise, react for 1h after the dropwise addition, and then add dropwise 16.10g formaldehyde solution, react for 1h, cool down to 60-65°C, then add dropwise a mixed solution of 5.40g hydroxylamine hydrochloride and 30.00g water, keep warm for 3h after the dropwise addition, take out and cool, and separate the product with a separatory funnel solution, and the lower layer was removed to obtain 3,4,5,-hydroxyl-2-oximinobenzoic acid rust conversion agent.

Embodiment 2

[0052] Synthesis of organic oxime rust conversion agent: Add 40.10g of methanol and 11.00g of toluene to a four-necked flask equipped with a stirring bar, a thermometer, a constant pressure dropping funnel and a condenser tube, and add 1.06g of Mg bars in batches at 65°C for reaction After 4.5h, after the reaction is complete, start to heat up to 70-75°C, and use a semi-continuous drop-in process to add a mixed solution of 1.35g gallic acid and 14.72gDMF dropwise. After the dropwise addition, react for 0.5h, then add dropwise 20.53g formaldehyde solution , reacted for 1 hour, lowered the temperature to 60-65°C, then added dropwise a mixed solution of 7.29g of hydroxylamine hydrochloride and 30.00g of water, and kept the reaction for 2.5 hours after the addition was completed. 3,4,5,-Hydroxy-2-oximinobenzoic acid rust converting agent was obtained from the lower layer.

Embodiment 3

[0054] Synthesis of organic oxime rust conversion agent: Add 42.05g of methanol and 13.01g of toluene to a four-necked flask equipped with a stirring bar, a thermometer, a constant pressure dropping funnel and a condenser tube, and add 1.00g of Mg bars in batches at 65°C for reaction 5h, after the reaction is complete, start to heat up to 70-75°C, add dropwise a mixed solution of 2.10g gallic acid and 18.90gDMF using a semi-continuous dropping process, react for 0.8h after the dropwise addition, and then add dropwise 21.20g formaldehyde solution, React for 0.5h, lower the temperature to 60-65°C, then add dropwise a mixed solution of 6.50g of hydroxylamine hydrochloride and 30.00g of water, keep it warm for 1h after the dropwise addition is complete, take it out and cool it down, separate the product with a separatory funnel, and remove the lower layer solution to obtain 3,4,5,-hydroxy-2-oximinobenzoic acid rust conversion agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com