Electrostatic tow separator

A technology of a filament separator and an electrostatic generator, which is used in the production of filaments, textiles and papermaking, etc., can solve the problems of easy generation of filaments and uneven distribution of tow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

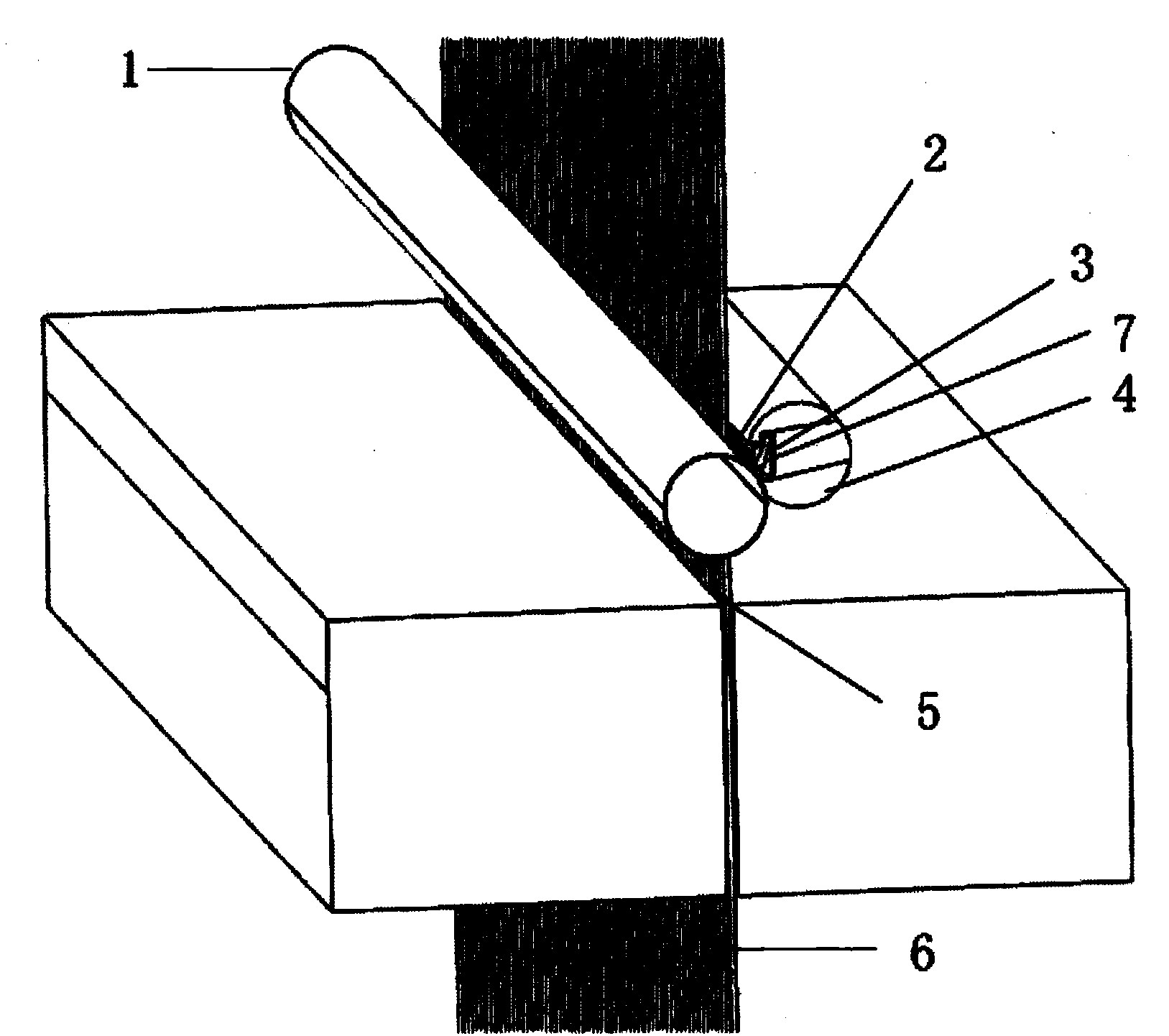

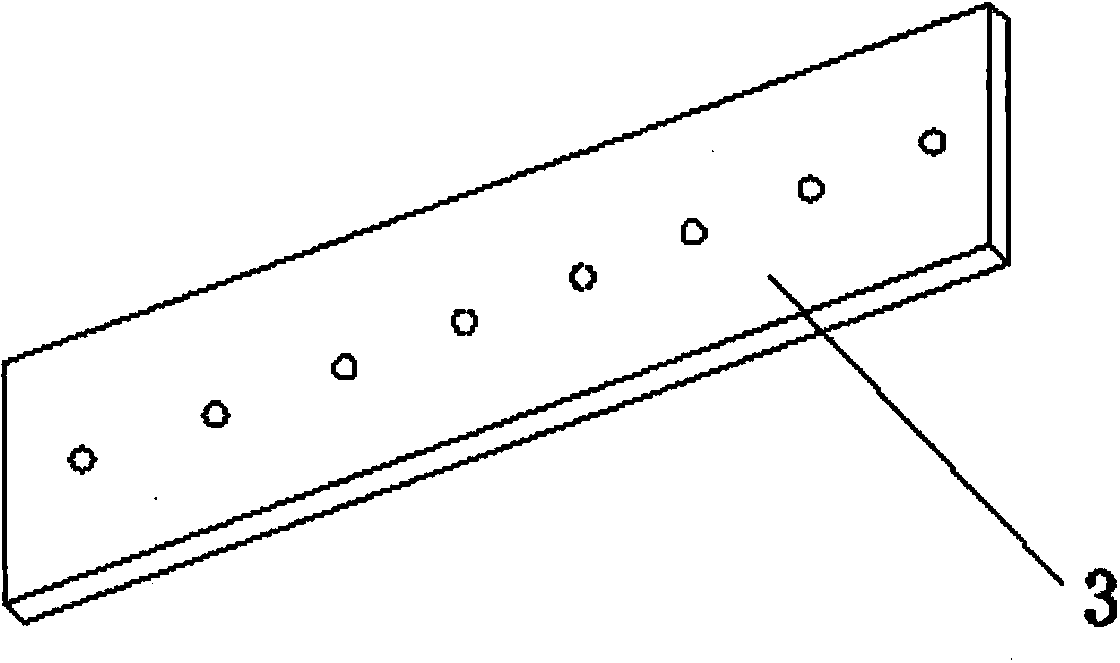

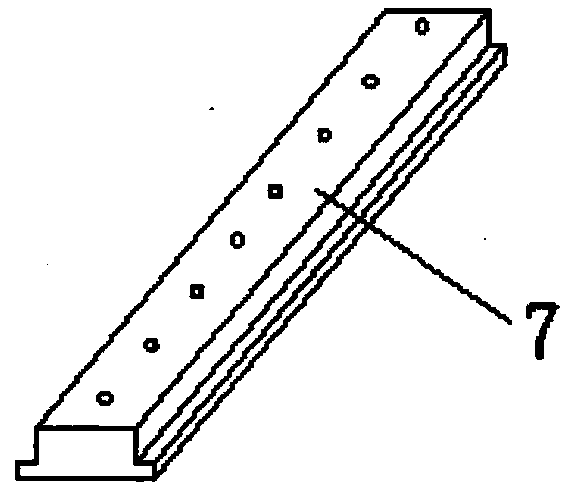

[0035] Such as Figure 1-5 As shown in FIG. 1 , it is a structural schematic diagram of the electrostatic splitter provided in Example 1, which includes the splitter main part and the target roller 1 respectively located on both sides of the tow 6. The target roller 1 is arranged in parallel with the splitter main part. The discharge needle 2 on the wire main part points to the target roll 1 and is perpendicular to the longitudinal section of the target roll 1 . The main part of the split wire includes a discharge needle plate 3 embedded with a plurality of discharge needles 2. The side of the discharge needle plate 3 embedded with the discharge needles 2 is provided with an anti-high voltage insulating material module 7, and the discharge needle 2 is formed from the anti-high voltage insulating material module. 7, the tip of the discharge needle 2 is located on the same plane as the outer surface of the anti-high voltage insulating material module 7. The distribution of the ...

Embodiment 2

[0040] The difference between this embodiment and Embodiment 1 is that the arrangement of the discharge needles 2 is different, such as Figure 5-8 As shown, the discharge needle board 3 has two discharge needles 2, and the even discharge needles 2 are located in the middle of the closest two of the odd discharge needles 2; The arrangement of the discharge needles matches the arrangement, and the position of the pinhole corresponds to the position of the discharge needle 2 on the discharge needle plate 3; the combination of the discharge needle plate 3, the anti-high voltage insulating material module 7 and the discharge needle 3 is as follows: Figure 8 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com