Damping type hinge pin support

A pin shaft and seismic type technology, applied in the direction of earthquake resistance, building components, building structures, etc., can solve the problems that the ear plate is easy to be broken, cannot guarantee the bearing capacity and deformation adaptability outside the plane of the support, and safety hazards, etc. Achieve the effects of reducing friction, improving rotation flexibility, and strong energy dissipation and shock absorption capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

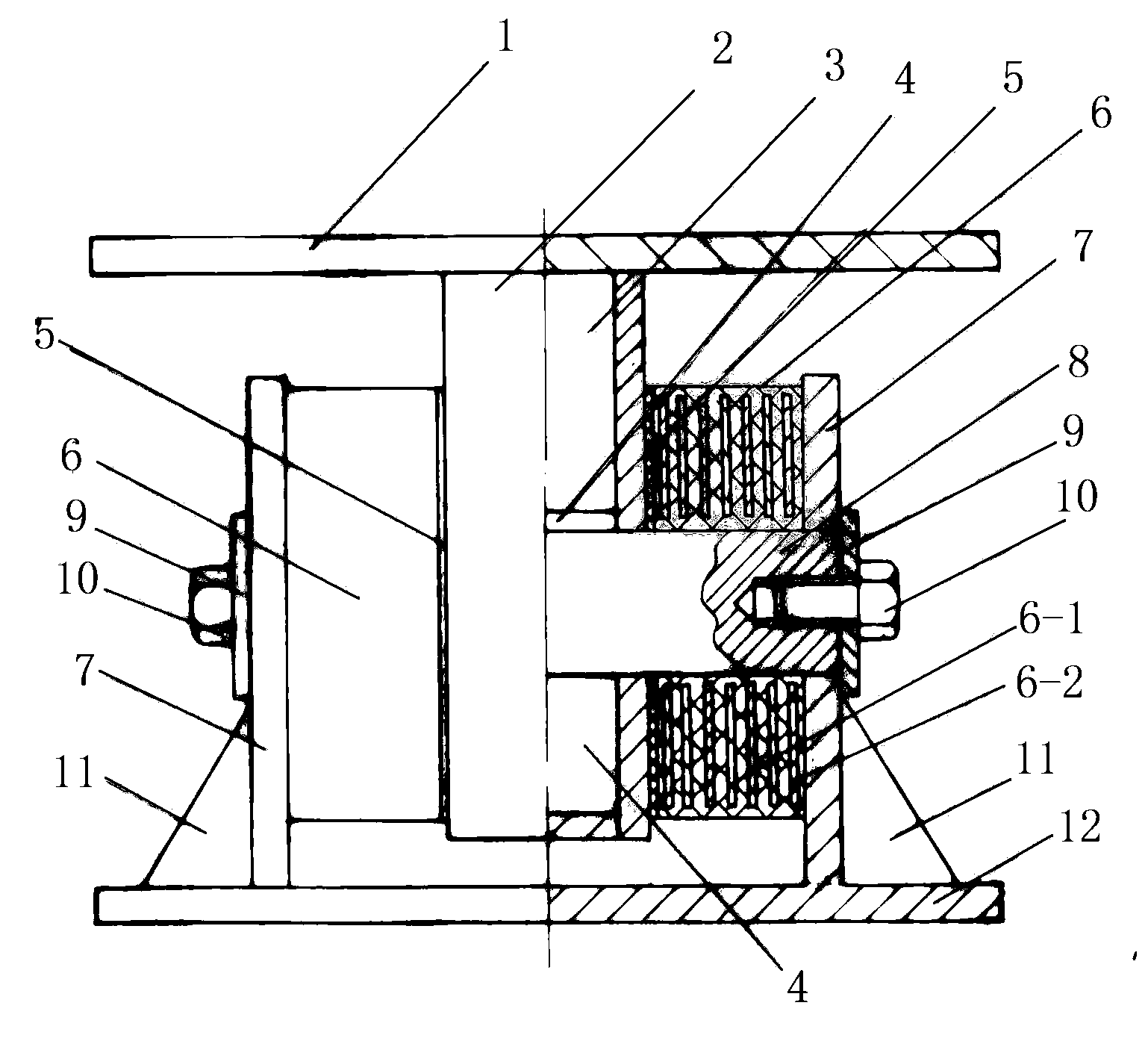

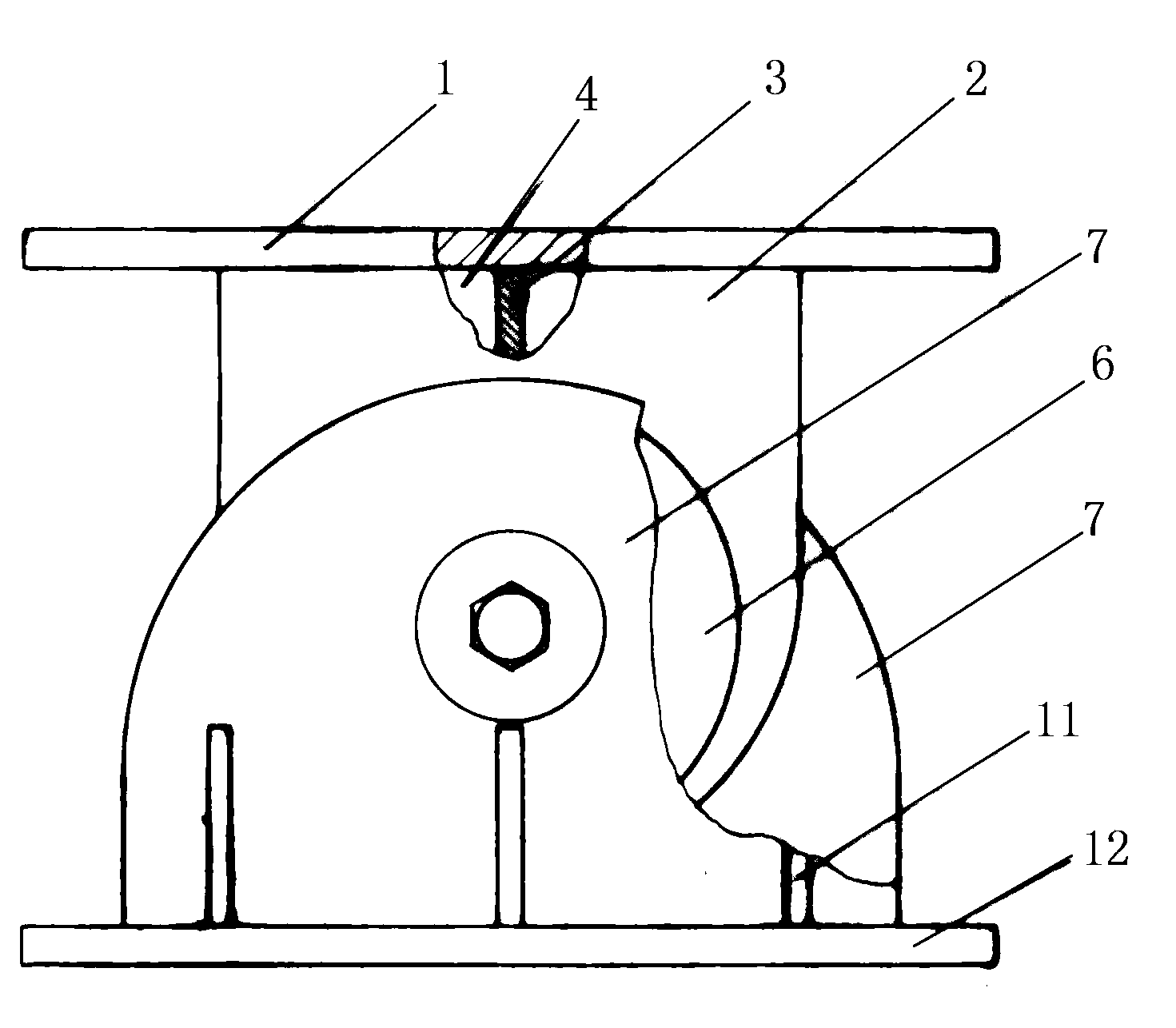

[0020] Depend on Figure 1-2 It can be seen from the illustrated embodiment that it includes an upper cover plate 1, a pair of lower ear plates 7, a pin shaft 8 and a bottom plate 12; it is characterized in that it also includes an upper ear plate 2 with a chamber 4 and a pair of shaft holes. High damping rubber combined spring body 6; a polytetrafluoroethylene layer 5 is respectively provided on one end surface of the pair of high damping rubber combined spring body 6; the upper ear plate 2 is fixed on the bottom surface center of the upper cover plate 1, The pair of lower ear plates 7 are symmetrically fixed on the bottom plate 12, and the pin shaft 8 passes through the lower ear plate 7 on the right side, the high damping rubber spring body 6 on the right side, the upper ear plate 2, and the high damping rubber spring body on the left side. After the shaft hole of the damping rubber spring body 6 and the lower ear plate 7 on the left side, it is fixedly connected by a shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com