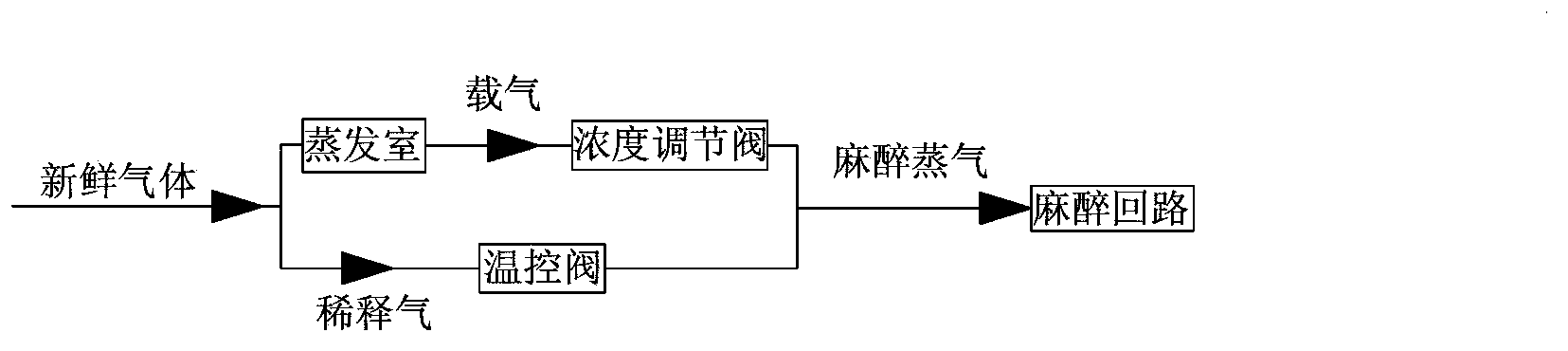

Pneumatic control valve for anesthetic evaporator and anesthetic evaporator control method implemented by pneumatic control valve

An anesthesia vaporizer and air control valve technology, which is applied in the field of anesthesia vaporizers, can solve the problems of vaporization pressure discharge, high cost, and danger in the non-evaporating chamber, and achieve the effects of solving anesthesia leakage, saving costs, and improving safety in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

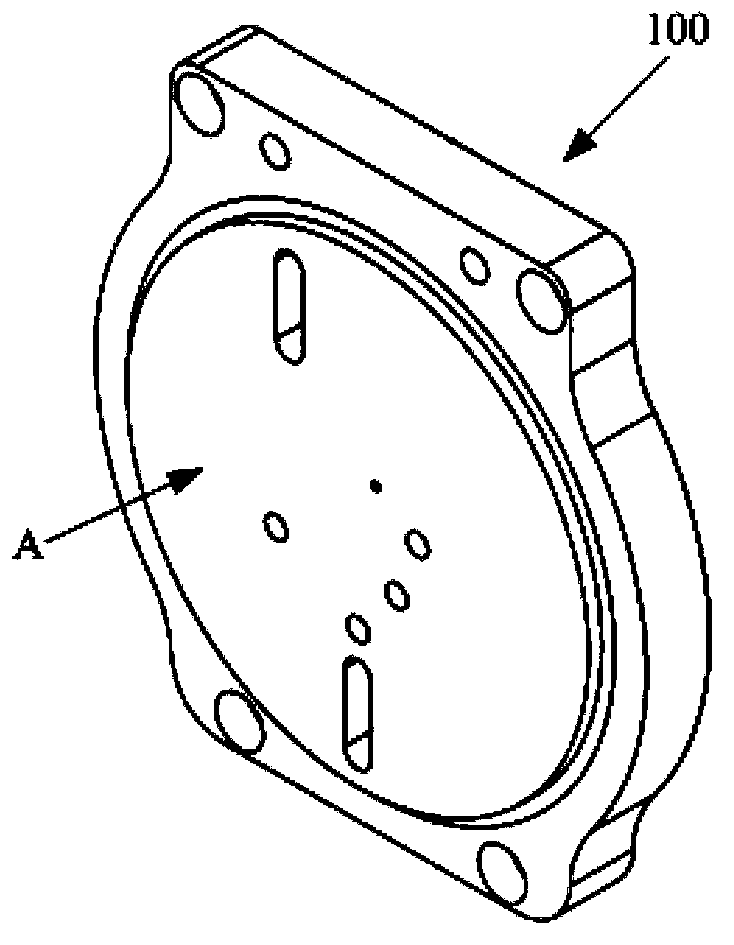

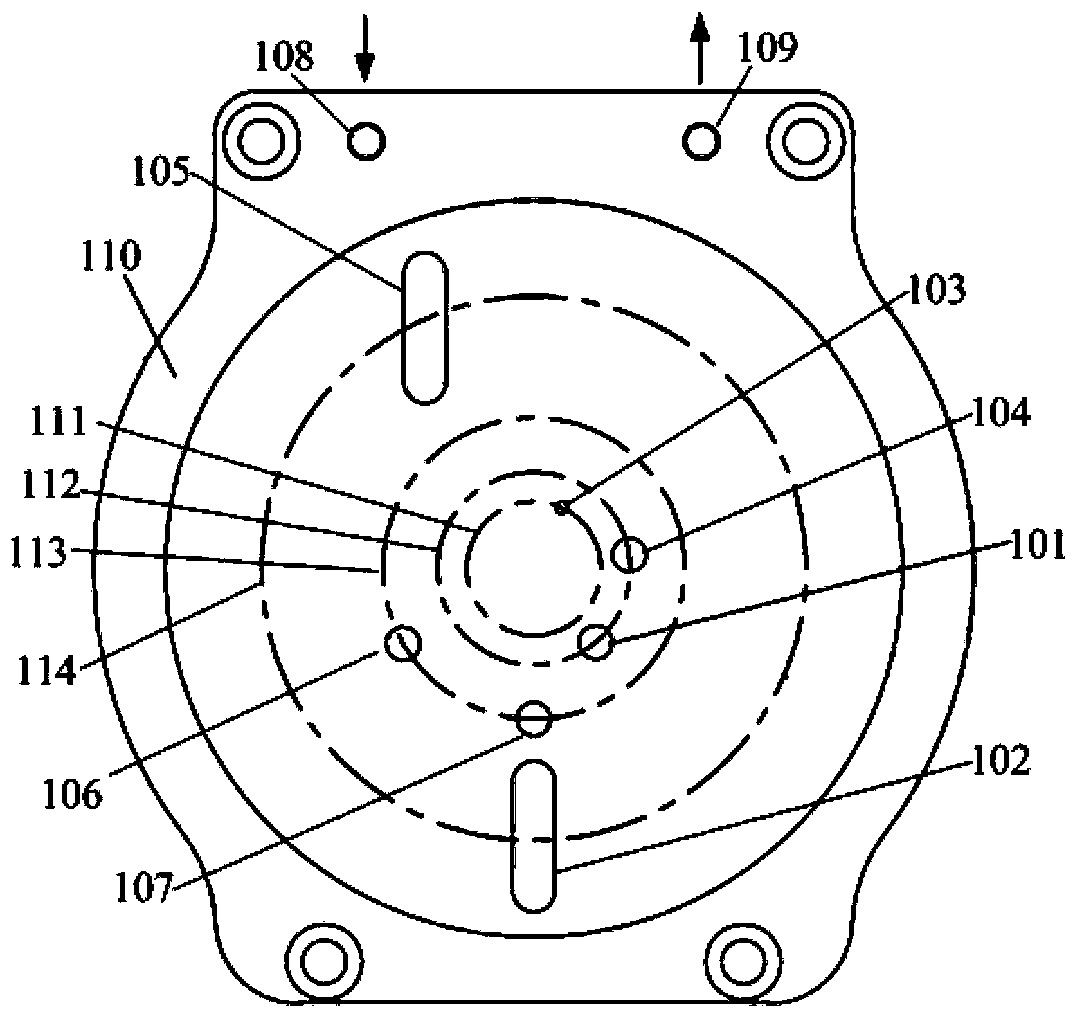

[0056] Such as Figure 2-5 As shown, an air-operated valve for an anesthesia vaporizer includes a valve seat 100 and a valve plate 200 arranged in contact with it. The valve plate 200 can rotate coaxially relative to the valve seat 100. The valve seat 100 has an air inlet 108 and an air outlet 109. And the gas channel inside the valve seat.

[0057] The valve seat 100 has a valve seat side 110 connected to the valve plate. The valve seat side 110 has four concentrically arranged annular areas with its center as the center of a circle. From the inside to the outside, there are first annular area 111 and second annular area 112. , the third annular area 113, the fourth annular area 114, the third air hole 103 connected with the evaporation chamber is opened in the first annular area 111, in order to release the evaporation pressure; the fourth air hole 104 is opened in the second annular area 112 and connected with The first air hole 101 connected to the evaporation chamber, th...

Embodiment 2

[0067] Such as Figure 9-12 As shown, an air-operated valve for an anesthesia vaporizer includes a valve seat 100 and a valve plate 200 arranged in contact with it. The valve plate 200 can rotate coaxially relative to the valve seat 100. The valve seat 100 has an air inlet 108 and an air outlet 109. And the gas channel inside the valve seat.

[0068] The valve seat 100 has a valve seat side 110 connected to the valve plate. The valve seat side 110 has three concentrically arranged annular areas with its center as the center of a circle. From the inside to the outside, there are first annular area 111 and second annular area 112. , the fourth annular area 114, in the first annular area 111, the third air hole 103 connected with the evaporation chamber is opened, in order to release the evaporation pressure; the fourth air hole 104 and the first air hole 103 connected with the evaporation chamber are opened in the second annular area 112 Gas hole 101, gas enters evaporation cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com