Spring steel wire heating, winding and cooling conveying device

A technology of spring steel wire and transmission device, applied in the direction of manufacturing springs from wires, heat treatment furnaces, manufacturing tools, etc., can solve problems such as safety accidents, inability to realize automatic production, and low efficiency, and achieve long service life, good heat treatment effect, and high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

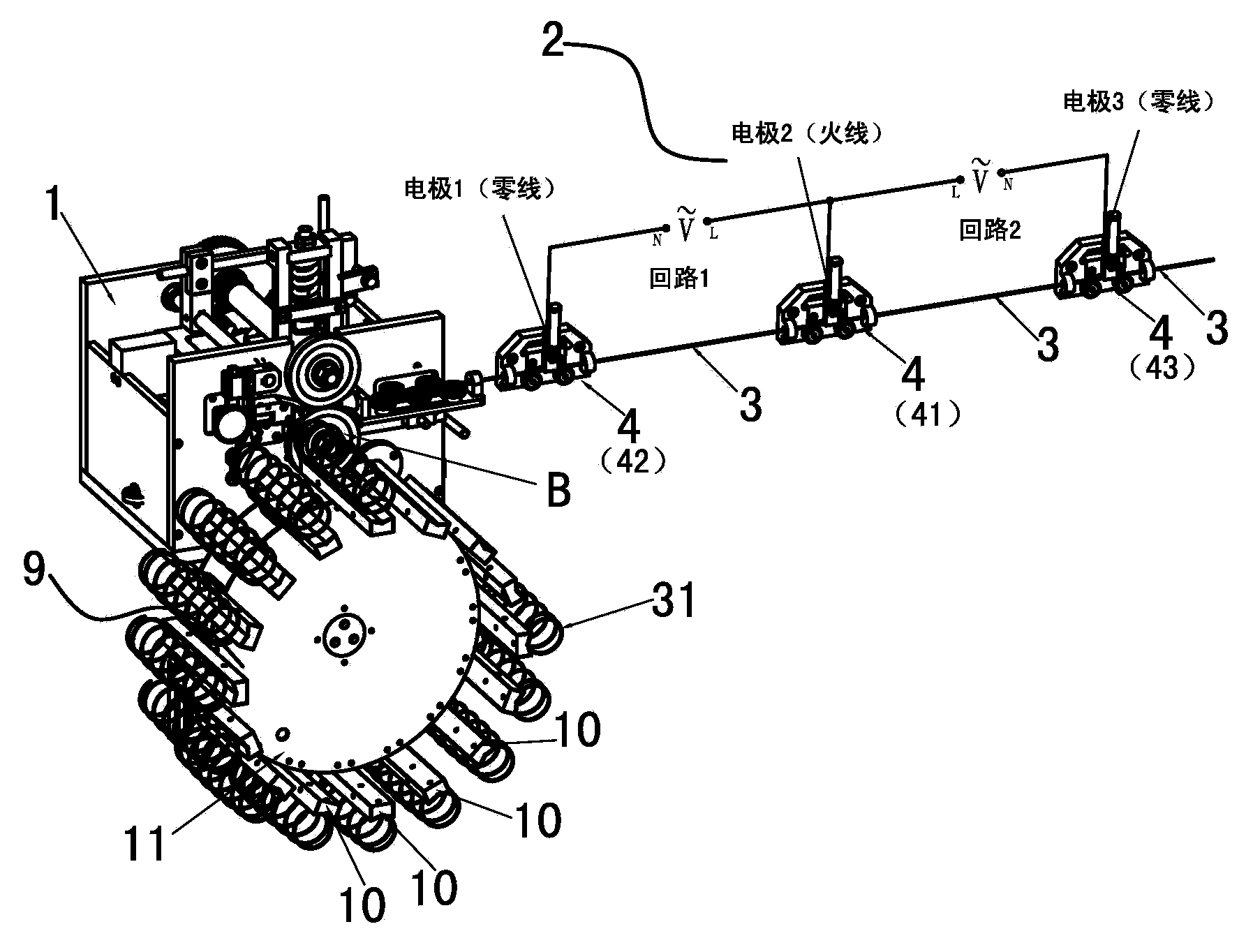

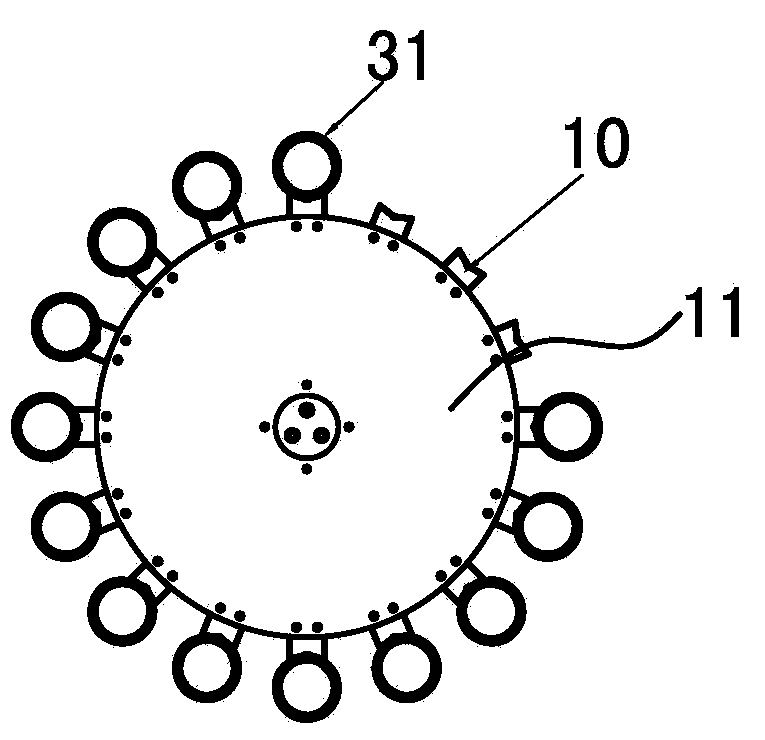

[0032] refer to Figure 1 to Figure 5 The shown spring steel wire heating winding and cooling conveying device includes a spring coiling machine 1 , a heating mechanism 2 and a spring cooling conveying mechanism 9 . The spring cooling conveying mechanism 9 includes an annular conveying mechanism 11 on which several magnetic suction blocks 10 are uniformly installed.

[0033] In the example

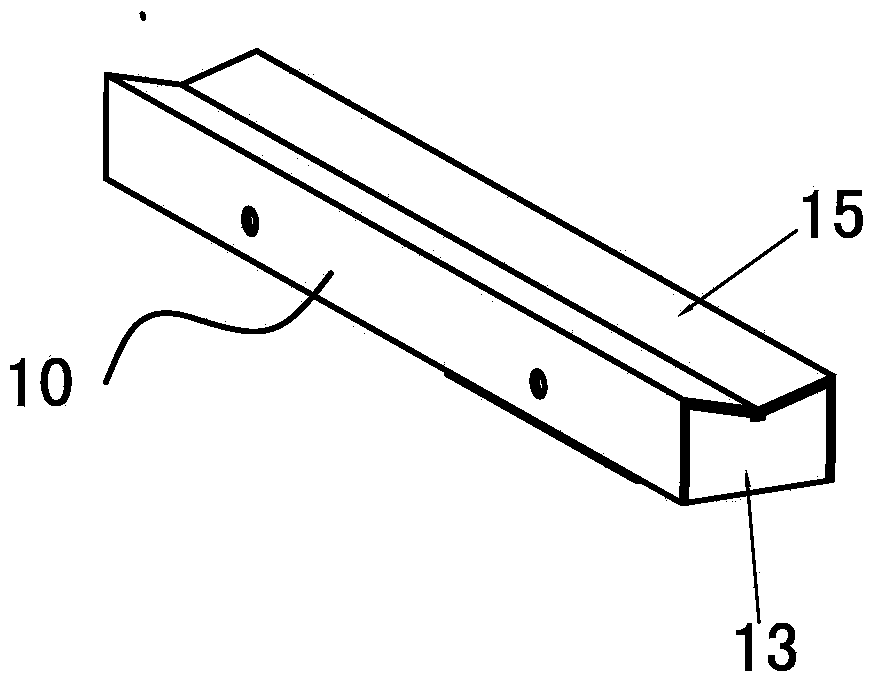

[0034] Described annular conveying mechanism 11 is a circular turntable, and magnetic block 10 is made of positioning seat 13, magnet 14 and gland 15, and described positioning seat 13 is a square box, and magnet 14 is placed in the square box; 15 is used for fixing and sealing the magnet 14 in the positioning seat 13. The gland 15 is a magnetically permeable gland, and the surface of the gland is set as a V-shaped surface or an arc surface. The spring cooling conveying mechanism 9 includes an annular conveying mechanism 11, and a turntable driving device drives the annular conveying mec...

Embodiment 2

[0043] like Figure 8 As shown, the technical characteristics of the spring steel wire heating coiling and cooling conveying device in this embodiment are: the endless conveying mechanism 11 shown is an endless conveyor belt, and the endless conveyor belt is driven by two driving runners 12 with grooves 121. Driven, the magnetic suction block 10 is installed on the endless conveyor belt, and rotates with the driving runner 12 to form a spring cooling transmission device. All the other are the same as the above embodiment. The endless conveyor belt of this embodiment can not only realize long-distance transportation, but also achieve the purpose of cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com