Dynamic vibration exerting method for aluminum alloy ultrasonic cleaning degassing

An aluminum alloy and ultrasonic technology, which is applied in the field of dynamic vibration application for ultrasonic purification and degassing of aluminum alloys, can solve problems such as affecting the efficiency of ultrasonic degassing and difficulty in floating, and achieve the effect of widely popularizing and applying value and improving the effect efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

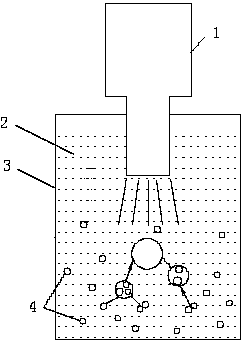

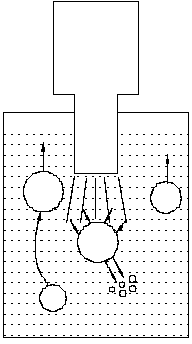

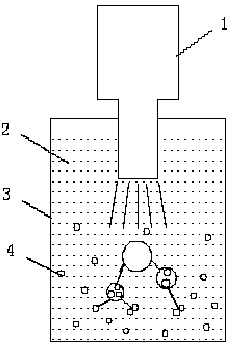

[0014] The present invention adopts dynamic intermittent vibration, that is, relative to static continuous vibration (traditional vibration method), the ultrasonic action is applied to the aluminum alloy melt for a period of time at an interval of Δt=20-30S, and the cycle is like this. The process of dynamic vibration ultrasonic degassing is as follows: image 3 , Figure 4 and Figure 5 As shown, after the ultrasonic vibration acts for a period of time, the vibration is stopped for a certain period of time, and then the ultrasonic vibration is continued, and so on. Such as image 3 As shown, after a period of ultrasonic action of the vibration transmission rod 1, a large number of cavitation nuclei are generated in the aluminum melt 2 in the mold 3, and the cavitation nuclei grow into cavitation bubbles 4, and the cavitation bubbles converg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com