Method used for preparing 1,4-dioxane from 1,3-dioxolane

A kind of technology of dioxane and dioxane, applied in the field of preparation 1

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

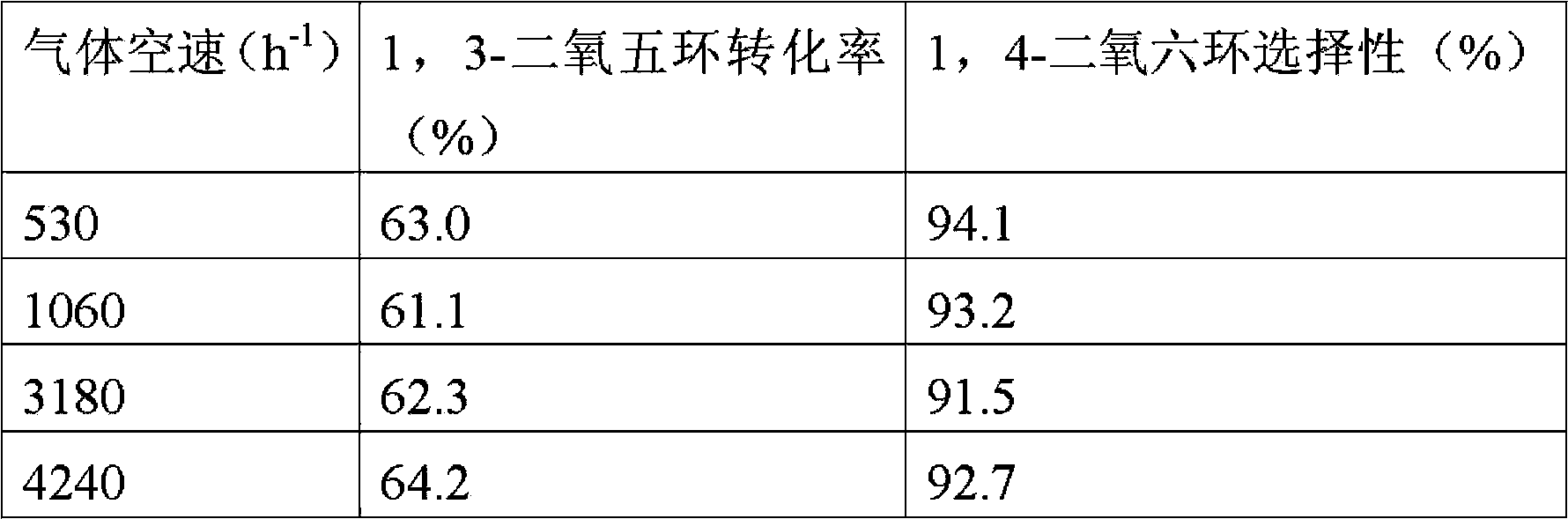

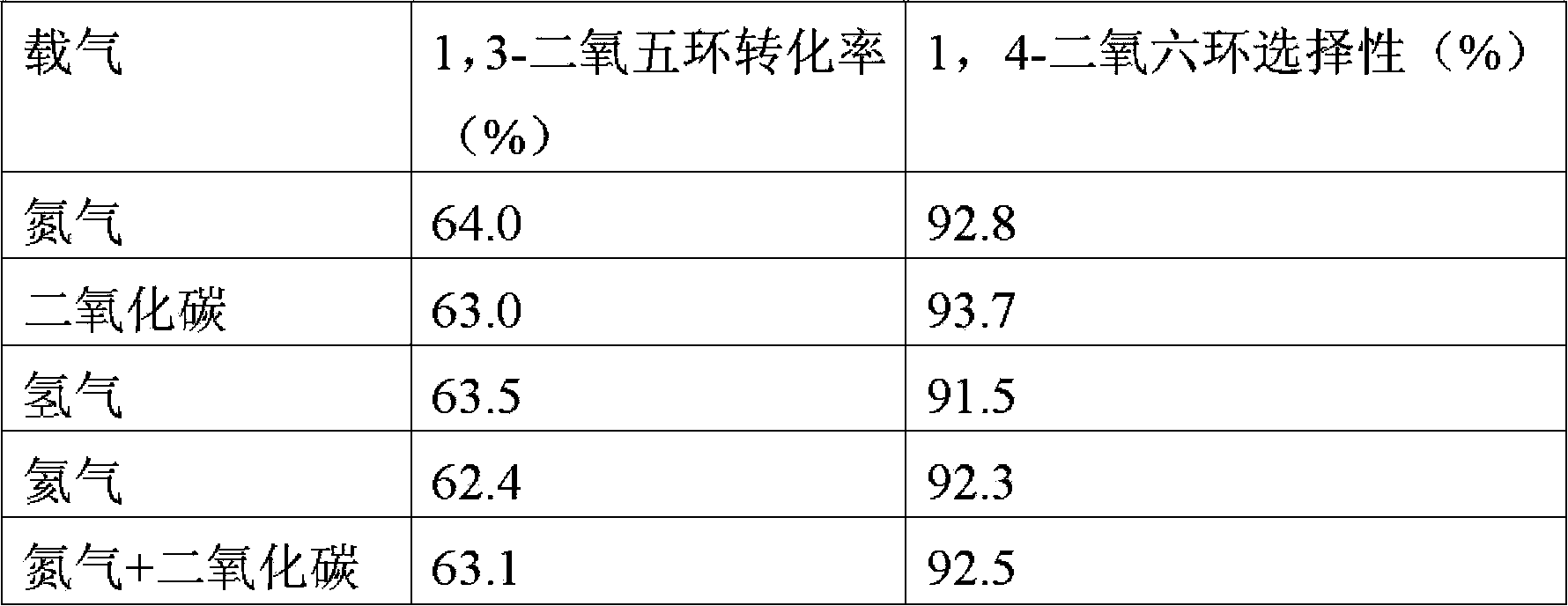

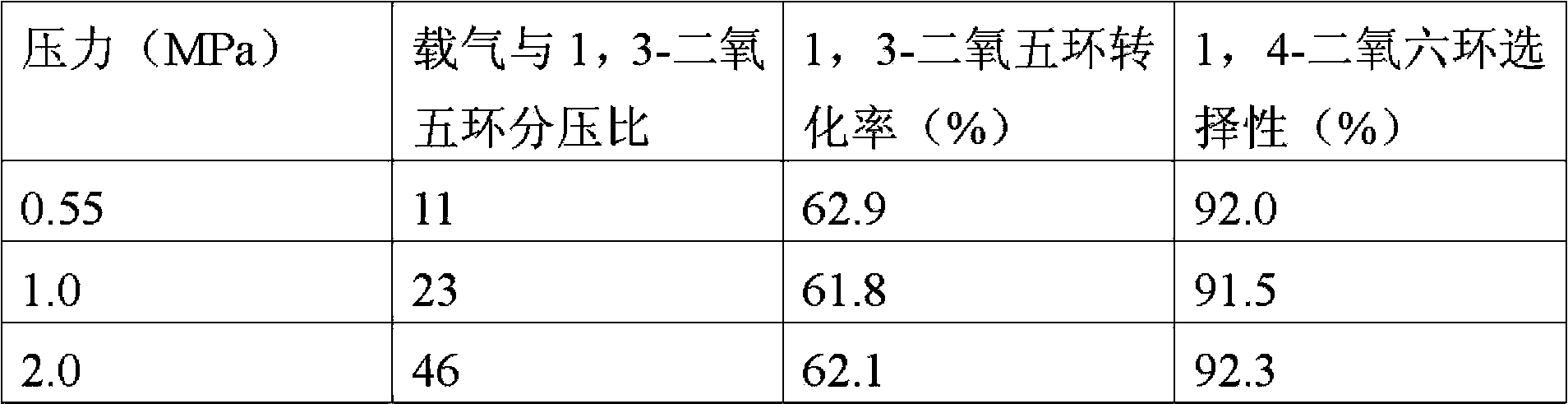

Examples

Embodiment 1

[0019] The 40-60 mesh catalyst obtained by pressing H-β (Si / Al=25) molecular sieve powder into tablets, crushing and sieving. Put 0.6g of catalyst into a reactor with an inner diameter of 8mm, raise the temperature to 500°C in a nitrogen atmosphere, keep the temperature at this temperature for 1h, and then cool down naturally to the reaction temperature of 130°C. Use the carrier gas CO to carry 1,3-dioxane into the reaction tube, the partial pressure of 1,3-dioxane is 42KPa (calculated by Clausius-Clapeyron), and the volume space velocity of CO is 2120h -1 , the reaction was carried out under normal pressure. The reactants were analyzed by online chromatography, the conversion rate of 1,3-dioxane was 64.3%, and the selectivity of 1,4-dioxane was 91.2%.

Embodiment 2

[0021] Other conditions were the same as in Example 1, and the catalytic performance of different solid acid catalysts to generate 1,4-dioxane from 1,3-dioxapenta was evaluated, and the reaction effluent was analyzed by online chromatography. The results are shown in Table 1.

[0022] Table 1

[0023] solid acid

Embodiment 3

[0025] Respectively at 120°C, 140°C, and 160°C, other conditions were the same as in Example 1, and the influence of temperature on the disproportionation of 1,3-dioxane to generate 1,4-dioxane was investigated, and the reaction effluent was obtained by online chromatography analyze. The results are shown in Table 2.

[0026] Table 2

[0027] temperature(℃)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com