Method for extracting rose essential oil

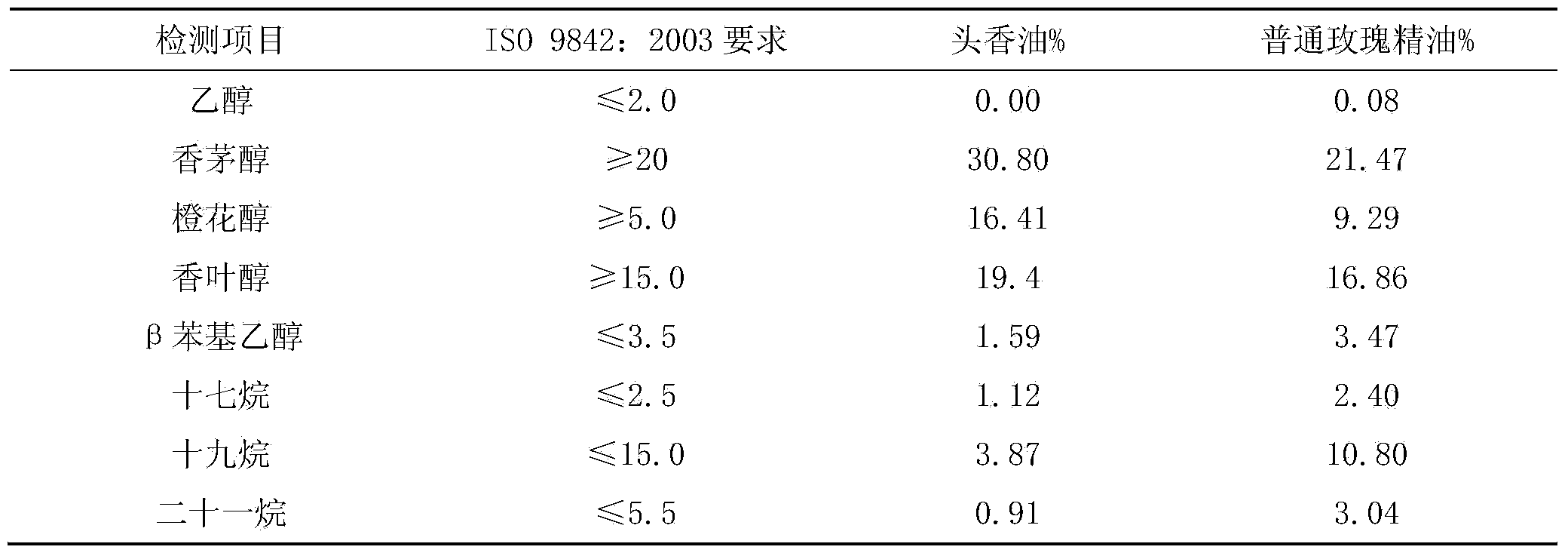

A technology of rose essential oil and extraction method, which is applied in the directions of essential oil/spice, fat generation, etc., can solve the problem of poor separation effect of rose essential oil and water layer, low extraction rate of "top sesame oil", and low total yield of "top sesame oil", etc. The problem is to avoid quality reduction, increase nerol content, and improve quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

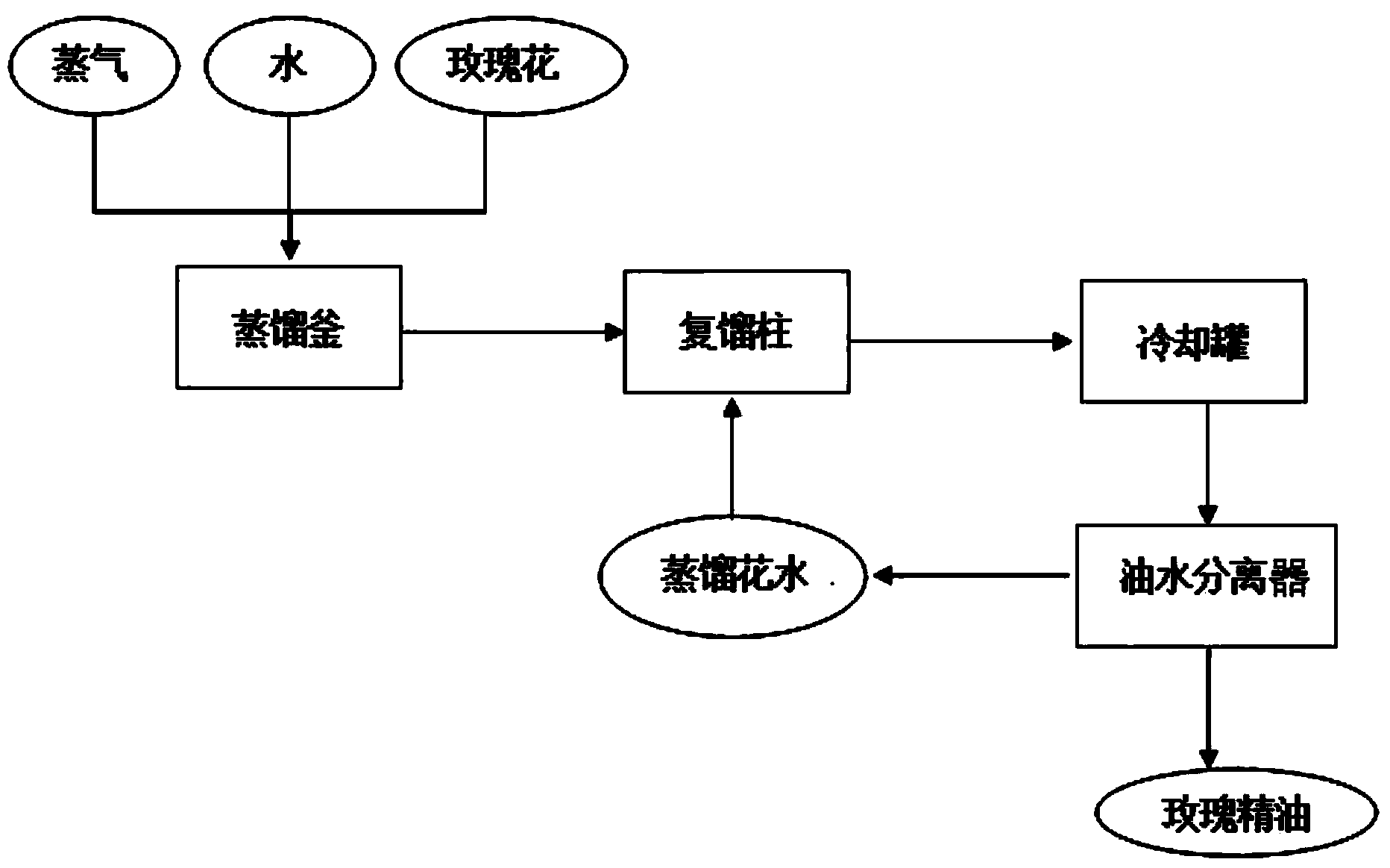

Method used

Image

Examples

Embodiment 1

[0033] (1) Put 300Kg rose flowers into the still and add 1200Kg of water, then feed steam to the bottom of the still to directly heat the roses and water, slowly heat up the roses and water in the still, heat for 35min, The liquid starts to boil; control the vacuum degree in the still to -0.06~-0.08MPa, the temperature to 90~96°C, and continue to distill for 4.5 hours. The column goes out of the distillation kettle to obtain the effluent;

[0034] (2) the effluent that comes out of the distillation kettle in the step (1) is passed into a condenser to condense, and the effluent obtains a liquid state effluent after being condensed by a condenser; the cooling process comprises two stages:

[0035] The first stage: in the first hour after boiling, the temperature of the escaping liquid is 26-30°C;

[0036] The second stage: after boiling for 1 hour to 4.5 hours after boiling, the temperature of the liquid that slips out is 30-40°C;

[0037] (3) The slip-out liquid in the step (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com