Simple and high-efficiency paper deacidification method

A deacidification method and paper technology, applied in the post-treatment of waste paper, etc., can solve the problems of chemical reagent toxicity, paper deformation, fading, etc., and achieve the effect of solving high equipment requirements, avoiding paper deformation, and delaying acidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

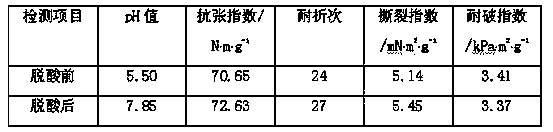

Embodiment 1

[0021] A simple and efficient paper deacidification method: build a net-shaped paper bracket in a closed space, connect the outlet of the ultrafine particle generator with the closed space, and place a 1% NaOH solution in an ultrasonic In the ultrafine particle generator, turn on the power of the ultrafine particle generator equipment, and process the deacidification solution into ultrafine particles. After testing, the diameter of the ultrafine particles is 2-10 μm. When the temperature in the closed space is 15°C and the air humidity reaches 80%RH , put the paper to be deacidified on the bracket in the space, make the paper contact with the ultrafine particles, so that the ultrafine particles evenly contact the paper fibers, after 12 minutes, the air humidity in the closed space is 82% RH, and the paper and ultrafine particles are finished. At this time, there are no obvious watermarks and wrinkles on the surface of the paper. Put the deacidified paper in another closed space...

Embodiment 2

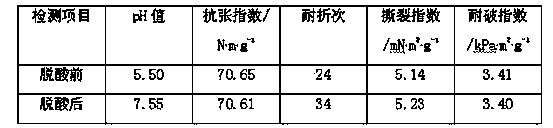

[0025] A simple and efficient paper deacidification method: connect the outlet of the air-compressed ultrafine particle generator to the closed space for deacidification, put the KOH solution with a concentration of 1% in the air-compressed ultrafine particle generator, and turn on the ultrafine particle generator. Microparticle generator equipment power supply, process the deacidification liquid into ultrafine particles, the diameter of ultrafine particles in the mist is 0.5-15μm, when the temperature in the closed space is 18°C, and the air humidity reaches 83%RH, put the paper to be deacidified in the space After 10 minutes on the bracket in the closed space, the humidity of the air in the closed space is 85% RH, and the contact between the paper and the ultrafine particles is ended. At this time, there are no obvious watermarks and wrinkles on the surface of the paper. After 12 hours of constant temperature and humidity in the space, take it out and place it in the air, and...

Embodiment 3

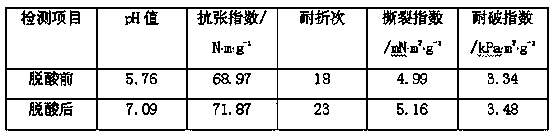

[0029] A simple and efficient paper deacidification method: connect the outlet of the ultrasonic ultrafine particle generator to the closed space for deacidification, and inject 2% Na 2 CO 3 Put the solution in an air-compressed ultrafine particle generator, turn on the power of the ultrafine particle generator equipment, and process the deacidified liquid into ultrafine particles. The diameter of the ultrafine particles in the mist is 2-11 μm. At 88% RH, put the paper to be deacidified on the bracket in the space for 10 minutes, the humidity of the air in the closed space is 90% RH, and the contact between the paper and the ultrafine particles is over. At this time, there is no obvious watermark and Wrinkle phenomenon, put the deacidified paper in another closed space with constant temperature and humidity for 12 hours, take it out and place it in the air, and let the water dry naturally at room temperature to meet the deacidification requirement. The pH of the paper after de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com