Improved drying production method for lung cleaning anti-inflammatory pills

A production method and technology for anti-inflammatory pills are applied in the field of improving the drying of Qingfei anti-inflammatory pills, which can solve the problems of shortening drying cycle, lowering production cost, difficulty in production scheduling, etc., so as to achieve shortening drying cycle, lowering production cost and flexible production arrangement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

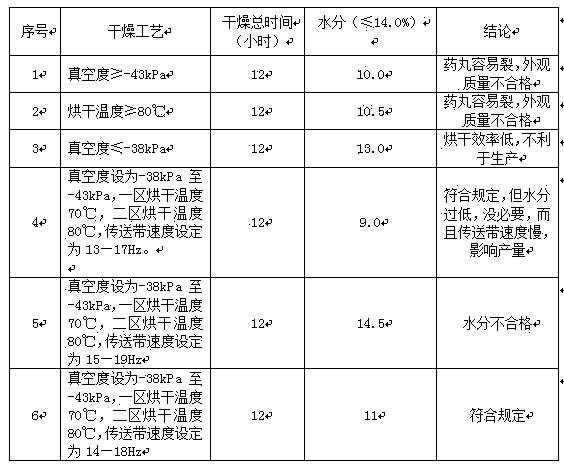

Method used

Image

Examples

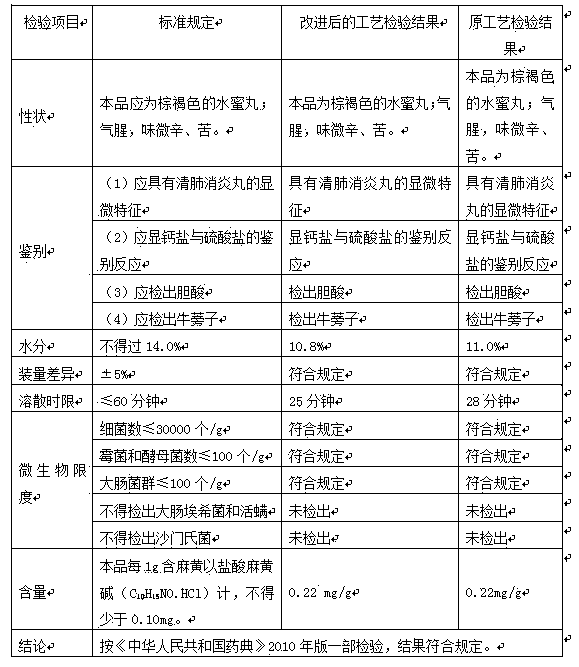

Embodiment 1

[0023] Program the vacuum degree, temperature, and conveyor belt speed of the vacuum continuous dryer with the machine. The vacuum degree is set to -41kPa, the drying temperature in the first zone is 70°C, the drying temperature in the second zone is 80°C, the first layer of conveyor belt is set at 14Hz, 2 The conveyor belt of the first layer is set to 15Hz, the conveyor belt of the third layer is set to 16Hz, the conveyor belt of the fourth layer is set to 17Hz, and the conveyor belt of the fifth layer is set to 18Hz, and then the Qingfei Xiaoyan pill wet pill is input;

[0024] Then test according to the method of Pharmacopoeia: Qingfei Xiaoyan Pills dissolving time limit is 25 minutes; water content is 10.8%, every 1g Qingfei Xiaoyan Pills contains ephedra and ephedrine hydrochloride (C 10 h 15 NO.HCl) is calculated as 0.22 mg.

Embodiment 2

[0026] Program the vacuum degree, temperature, and conveyor belt speed of the vacuum continuous dryer with the machine. The vacuum degree is set to -40kPa, the drying temperature in the first zone is 70°C, the drying temperature in the second zone is 80°C, the first layer of conveyor belt is set at 14Hz, 2 The conveyor belt of the first layer is set to 15Hz, the conveyor belt of the third layer is set to 16Hz, the conveyor belt of the fourth layer is set to 17Hz, and the conveyor belt of the fifth layer is set to 18Hz, and then the Qingfei Xiaoyan pill wet pill is input;

[0027] Then test according to the method of Pharmacopoeia: Qingfei Xiaoyan Pills dissolving time limit is 26 minutes; water content is 10.7%, every 1g Qingfei Xiaoyan Pills contains ephedra and ephedrine hydrochloride (C 10 h 15 NO.HCl) is calculated as 0.20 mg.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap