Drying equipment and drying method

A drying equipment and drying method technology, applied in the field of printing and dyeing auxiliaries, can solve problems such as danger, and achieve the effects of easy operation, avoiding contact and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

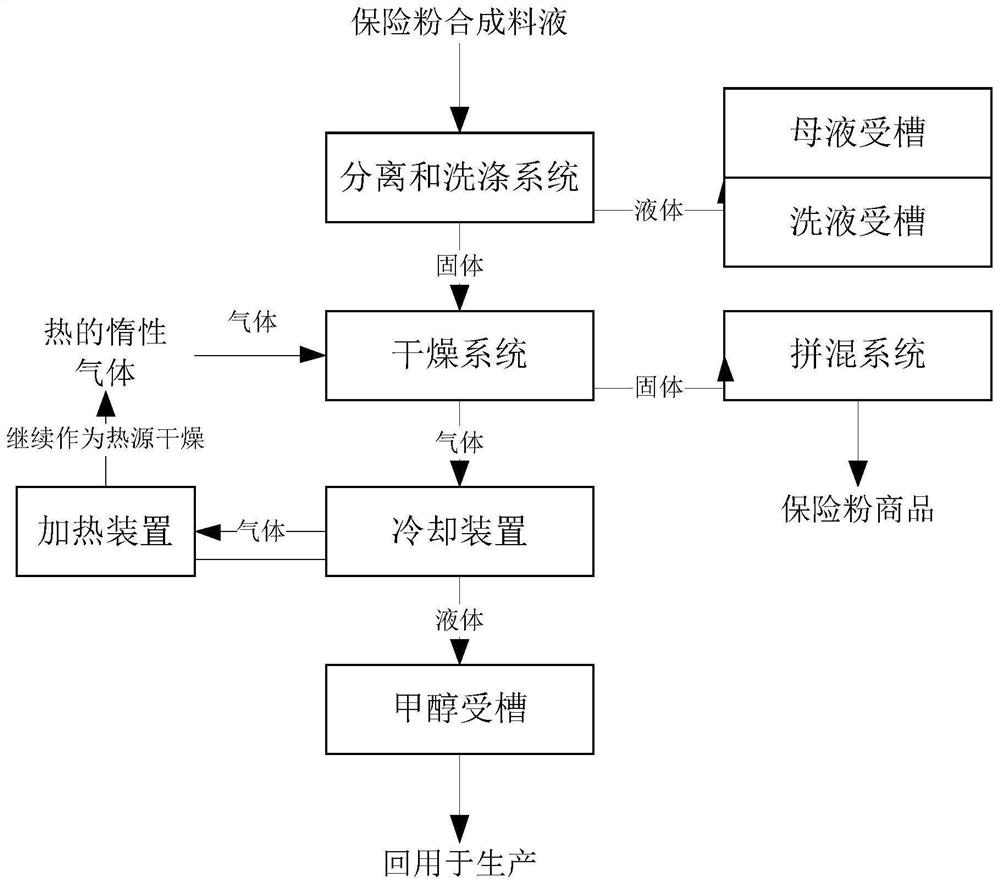

Method used

Image

Examples

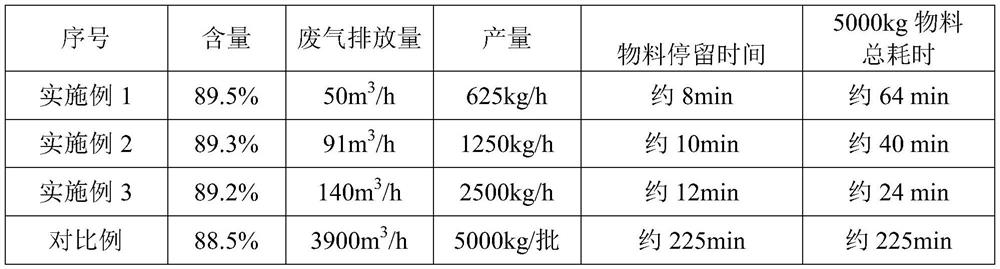

Embodiment 1

[0081] 2600 kg of sodium formate is dissolved in methanol 3M 3 And mother liquor 8m 3 Medium, material A; 3M of sodium sulfite and 3m sodium sulfate 3 Mix, then adopt sulfur dioxide 800 kg to prepare material B; mix the material A and the material B slowly mixed, and the mixture is mixed, and the sulfur dioxide is 1500 kg, and the ethane is 110 kg as the reaction inhibitor, temperature at 84 ° C. The reaction was carried out under pressure at 0.2 MPa to obtain an insurance powder.

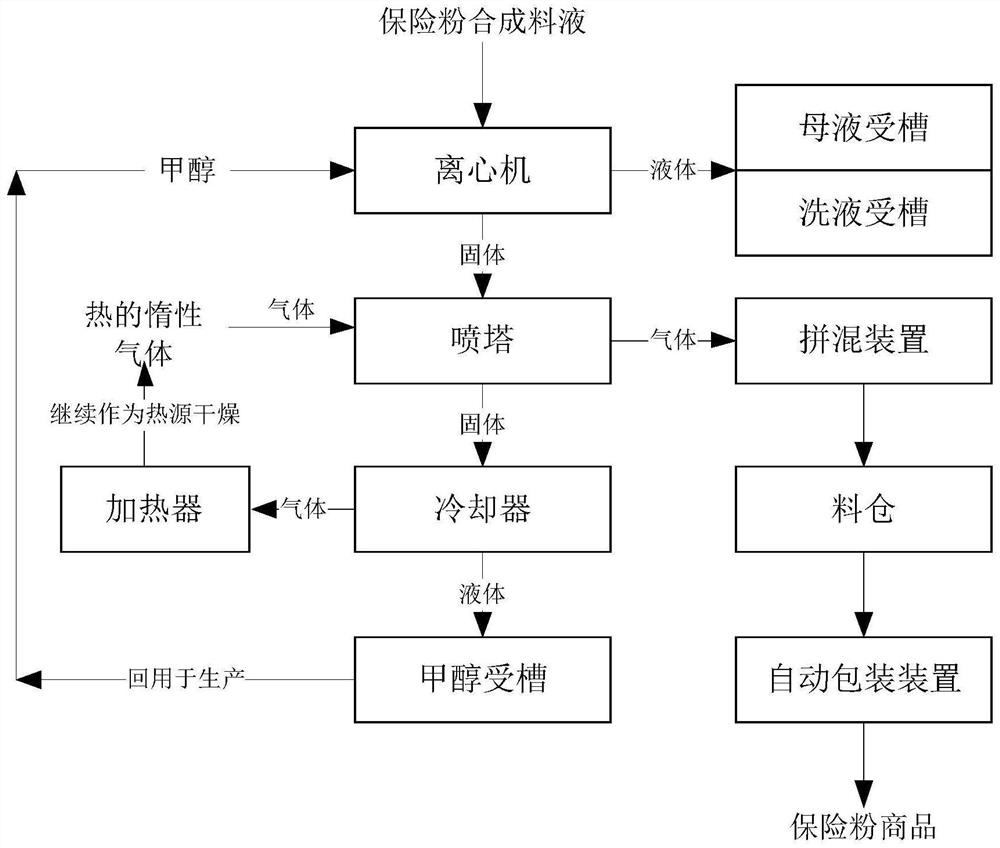

[0082] Such as figure 2 As shown, the synthesized insurance powder is in a material, cooled to 65 ° C, transported with nitrogen, according to 1M 3 The speed of the / h continuously presss in the automatic sleeve centrifuge, dry and 1M 3 After washing of the methanol of / h, the spiral conveyor was fed into the spray tower, and after the solid material in the spray tower was converted from the hot nitrogen gas of about 64 ° C, the nitrogen gas was evaporated together with the methanol in the solid mate...

Embodiment 2

[0086] 2600 kg of sodium formate is dissolved in methanol 3M 3 And mother liquor 8m 3 Medium, material A; 3M of sodium sulfite and 3m sodium sulfate 3 Mix, then adopt sulfur dioxide 800 kg to prepare material B; mix the material A and the material B slowly mixed, and the mixture is mixed, and the sulfur dioxide is 1500 kg, and the ethane is 110 kg as the reaction inhibitor, temperature at 84 ° C. The reaction was carried out under pressure at 0.2 MPa to obtain an insurance powder.

[0087] Such as figure 2 As shown, the synthesized insurance powder is in a material, cooled to 75 ° C, transported with nitrogen, and press 2M. 3 The speed of / h continuously in the automatic filter, continued to use 2M after pressure drying 3 After washing of the methanol of / h, the spiral conveyor was fed into the spray tower, and after the solid material in the spray tower was converted from the hot nitrogen gas of about 64 ° C, the nitrogen gas was evaporated together with the methanol in the sol...

Embodiment 3

[0091] 2600 kg of sodium formate is dissolved in methanol 3M 3 And mother liquor 8m 3 Medium, material A; 3M of sodium sulfite and 3m sodium sulfate 3Mix, then adopt sulfur dioxide 800 kg to prepare material B; mix the material A and the material B slowly mixed, and the mixture is mixed, and the sulfur dioxide is 1500 kg, and the ethane is 110 kg as the reaction inhibitor, temperature at 84 ° C. The reaction was carried out under pressure at 0.2 MPa to obtain an insurance powder.

[0092] Such as figure 2 As shown, the synthesized insurance powder is in a material, cooled to 70 ° C, transported with nitrogen, according to 4M 3 The speed of / h continuously in the automatic filter, continue to use 4M after pressure drying 3 After washing of the methanol of / h, the spiral conveyor was fed into the spray tower, and after the solid material in the spray tower was converted from the hot nitrogen gas of about 64 ° C, the nitrogen gas was evaporated together with the methanol in the sol...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap