Ceramic thin film thermocouple and manufacture method thereof

A technology of ceramic thin film and thermocouple, which is applied in the direction of directly heat-sensitive electrical/magnetic element thermometers, measuring heat, and using electrical devices, etc., can solve the problems of high cost, low test temperature range, large error, etc., to achieve Low cost and wide temperature measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

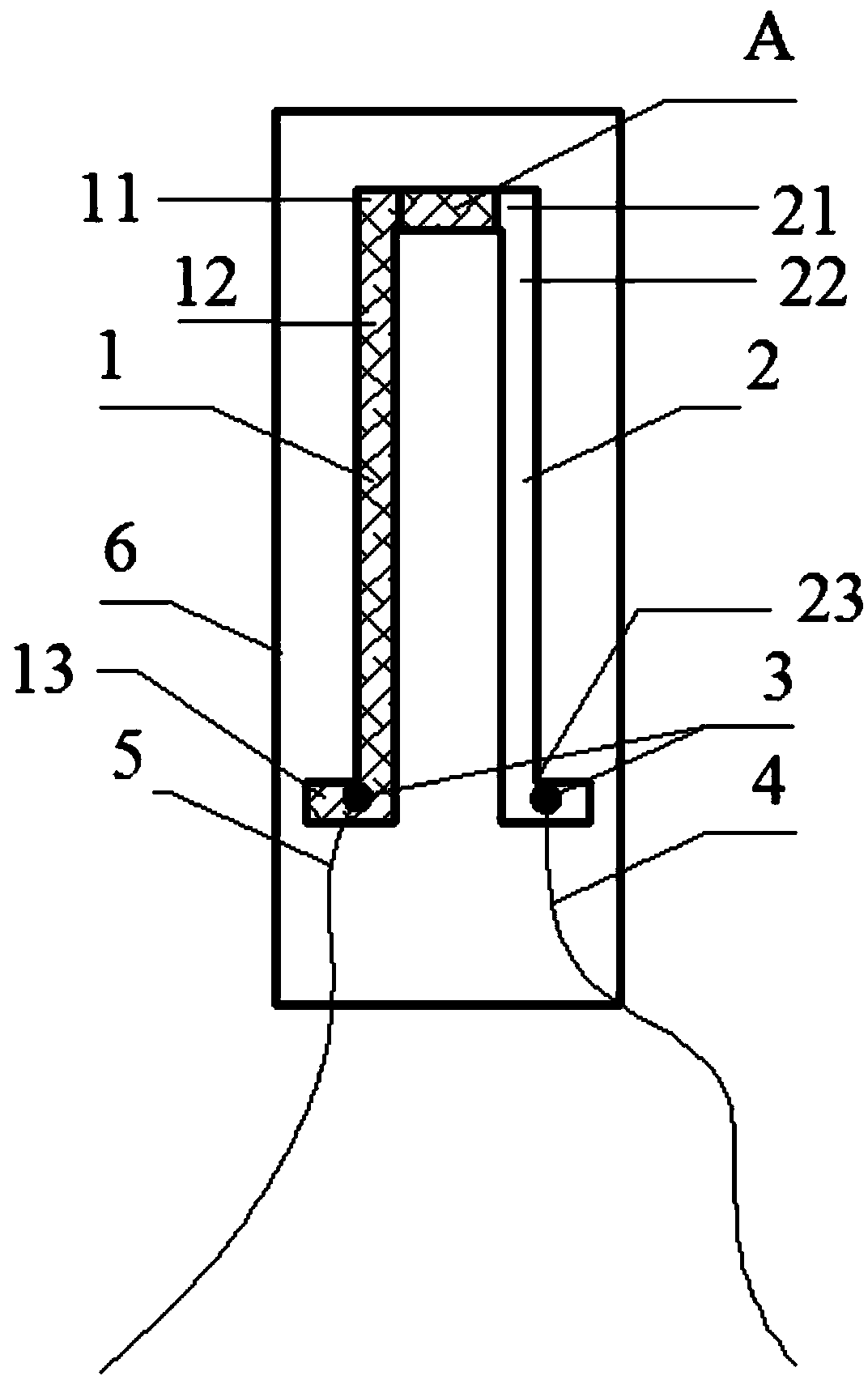

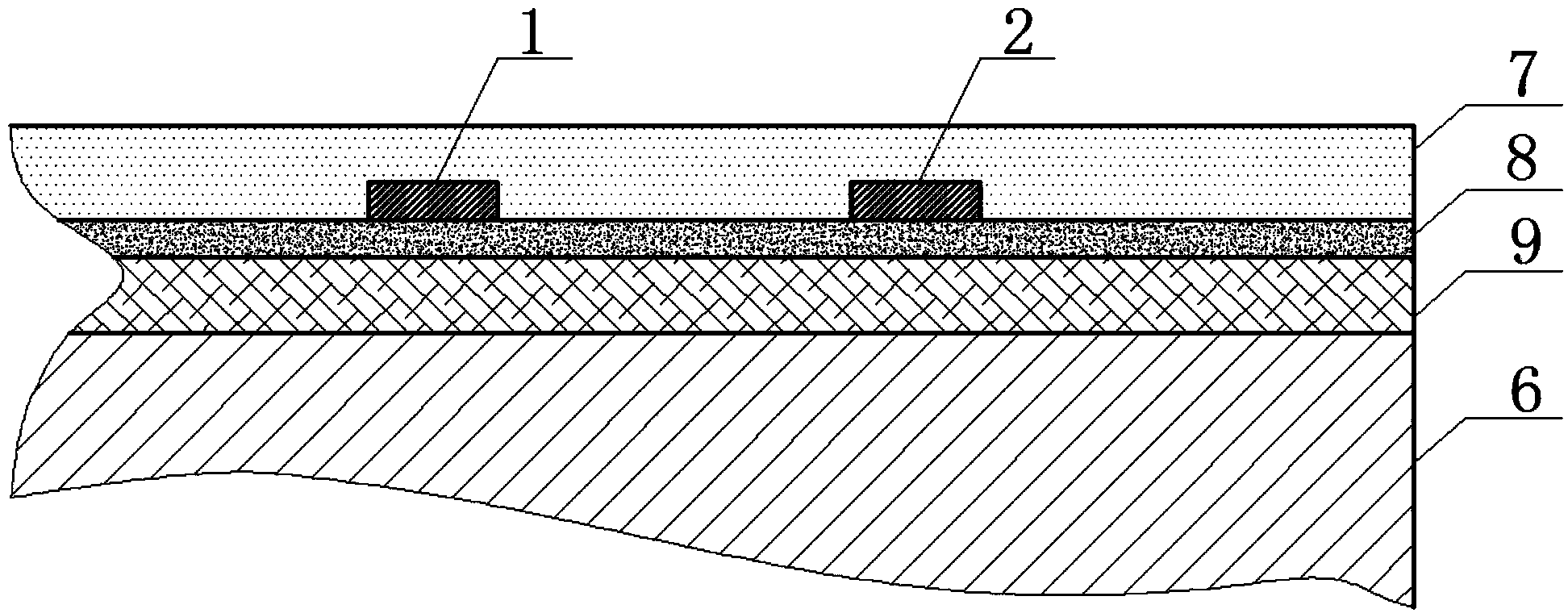

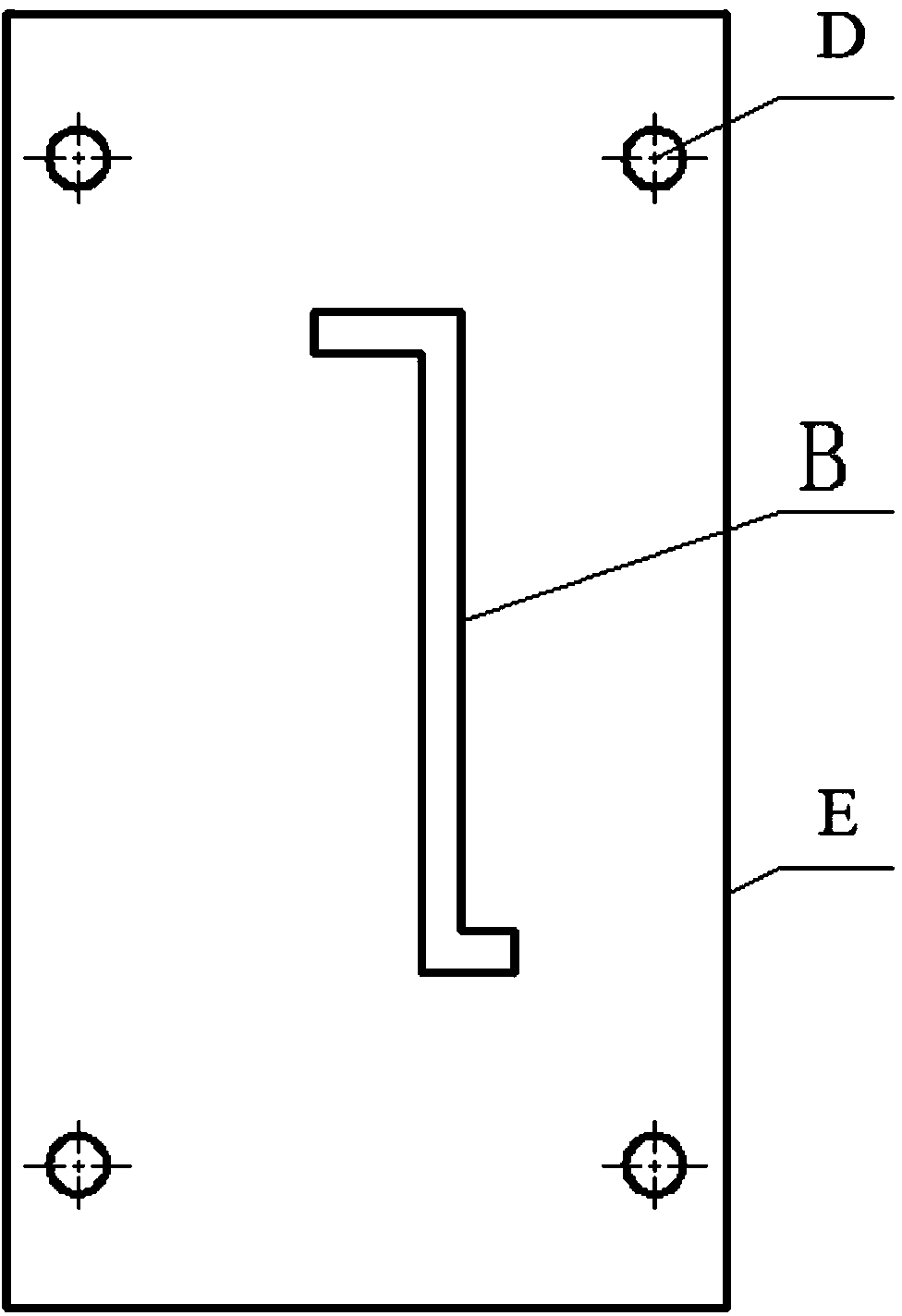

[0017] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

[0018] The invention is mainly improved from three aspects: 1. New thin-film thermocouple materials ITO (tin-doped indium oxide) and AZO (aluminum-doped zinc oxide) are used as the thermal electrode materials of the thermocouple; 2. The ceramic thin-film thermocouple 3. Improvement of the structure of the thermocouple film layer.

[0019] 1. Using a new type of ceramic film material, ITO (tin-doped indium oxide) ceramic material and AZO (aluminum-doped zinc oxide) ceramic material are used as the thermal electrode material of the thermocouple; ITO is an n-type semiconductor material with high conductivity. , high mechanical hardness and good chemical stability; AZO is obtained by doping Al in the ZnO system, AZO is also an n-type semiconductor material similar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com