Sample cell for infrared detection of germanium tetrachloride and silicon tetrachloride

A technology of silicon tetrachloride and infrared detection, which is applied in the direction of measuring devices, sampling devices, and material analysis through optical means, can solve the problems of non-removable cleaning, sample measurement errors, and inconvenient observation of germanium lens corrosion, etc., to achieve sealing Good effect, improve accuracy, avoid contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

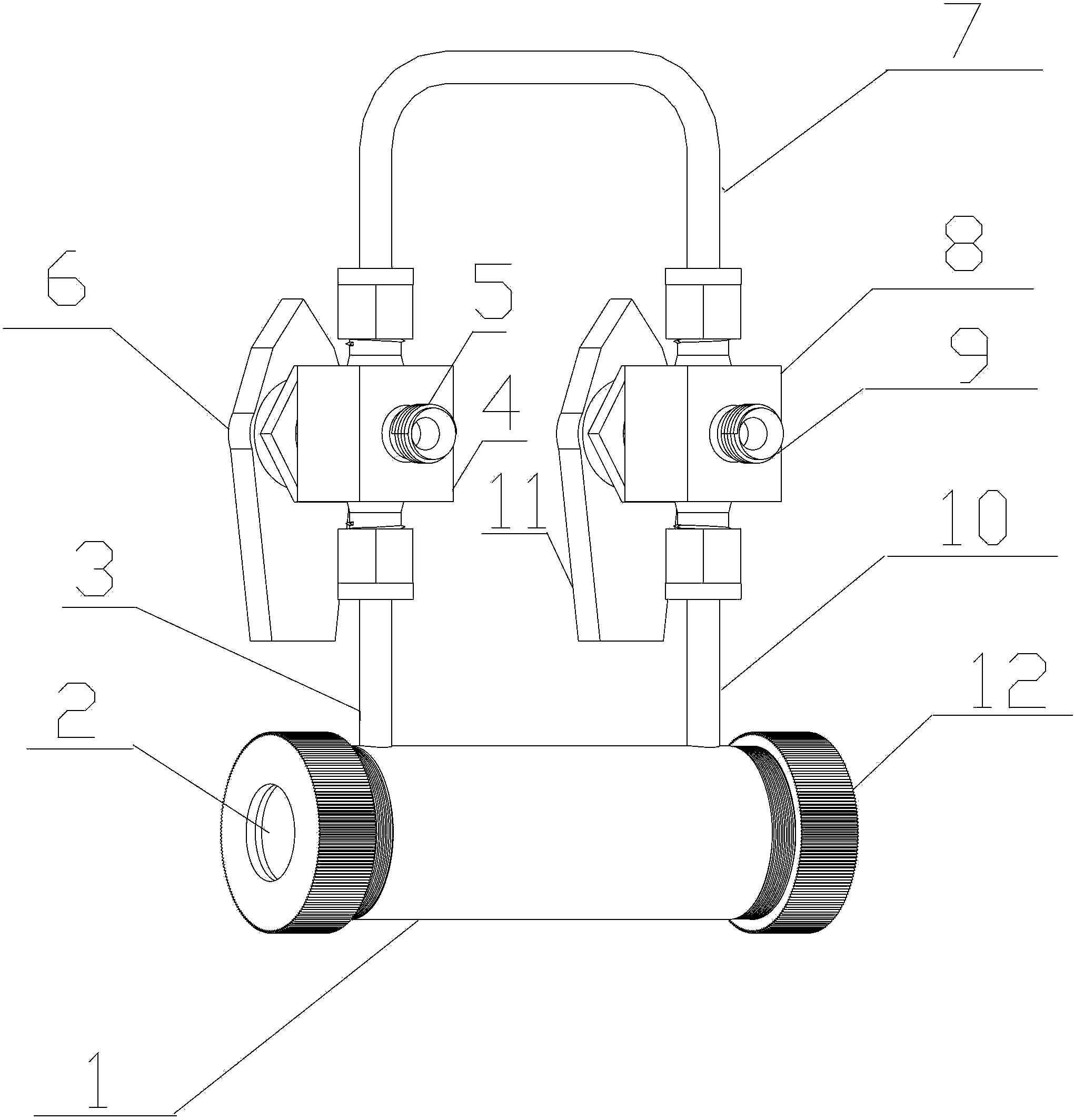

[0022] Connect the outlet of the germanium tetrachloride system to be tested with the inlet 5 of the three-way ball valve of the sample pool (L=100mm), connect the outlet 9 of the three-way ball valve of the sample pool with the tail gas receiving bottle, and open the outlet three in sequence. Through ball valve rotary handle 11 and feed three-way ball valve rotary handle 6, germanium tetrachloride samples enter from the three-way ball valve feed port 5 during sampling, and when liquid flows out of the sample pool three-way ball valve discharge port 9, they are closed sequentially Feeding three-way ball valve rotary handle 6 and outlet material three-way ball valve rotary handle 11. The sampling process ends.

[0023] The mid-infrared measurement results of germanium tetrachloride are as follows:

[0024] wave number cm -1 (Impurities) Transmittance (%) 3610±2cm -1 (GeCl 3 Oh) 97.5 2970~2925cm -1 (CH) 99 2860~2830cm -1 (HCl) 99.51 2336±...

Embodiment 2

[0027] Connect the system discharge port of silicon tetrachloride to be tested with the feed port 5 of the three-way ball valve of the sample pool (L=100mm), connect the discharge port 9 of the three-way ball valve of the sample pool with the tail gas receiving bottle, and open the three-way discharge port in sequence. Through ball valve rotary handle 11 and feeding three-way ball valve rotary handle 6, silicon tetrachloride samples enter from the three-way ball valve feed port 5 during the sampling process, and when liquid flows out of the three-way ball valve outlet 9 in the sample pool, they are closed sequentially Feed three-way ball valve rotating handle 6 and outlet material three-way ball valve rotating handle 11. The sampling process ends.

[0028] The infrared measurement results of the silicon tetrachloride sample are as follows:

[0029] Wavenumber cm -1 (Impurities) Transmittance (%) 3666cm -1 (SiCl 3 Oh) 97.05 3100-3020cm -1 (CH aromat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com