Device and method device for evaluating catalyst during preparation of oxalate through three-channel automatic CO gas phase oxidative coupling

An oxidative coupling and evaluation device technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of slow catalyst development, large equipment capital investment, and low analysis efficiency, so as to ensure repeatability and equipment capital investment. Large, low analytical efficiency effects

Active Publication Date: 2014-07-02

FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

View PDF14 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Aiming at the deficiencies and problems of the existing catalyst evaluation device and catalyst evaluation method for the preparation of oxalate by CO gas-phase oxidation coupling, the present invention provides a three-channel automatic CO gas-phase oxidation coupling preparation of oxalate catalyst evaluation device and The catalyst evaluation method realizes the simultaneous evaluation of the performance of three catalysts, and solves the technical problems existing in the existing evaluation devices and methods: 1. The catalyst development speed is slow; 2. The analysis efficiency is low; 3. The analysis is not synchronized; 4. The equipment large capital investment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Login to View More

Abstract

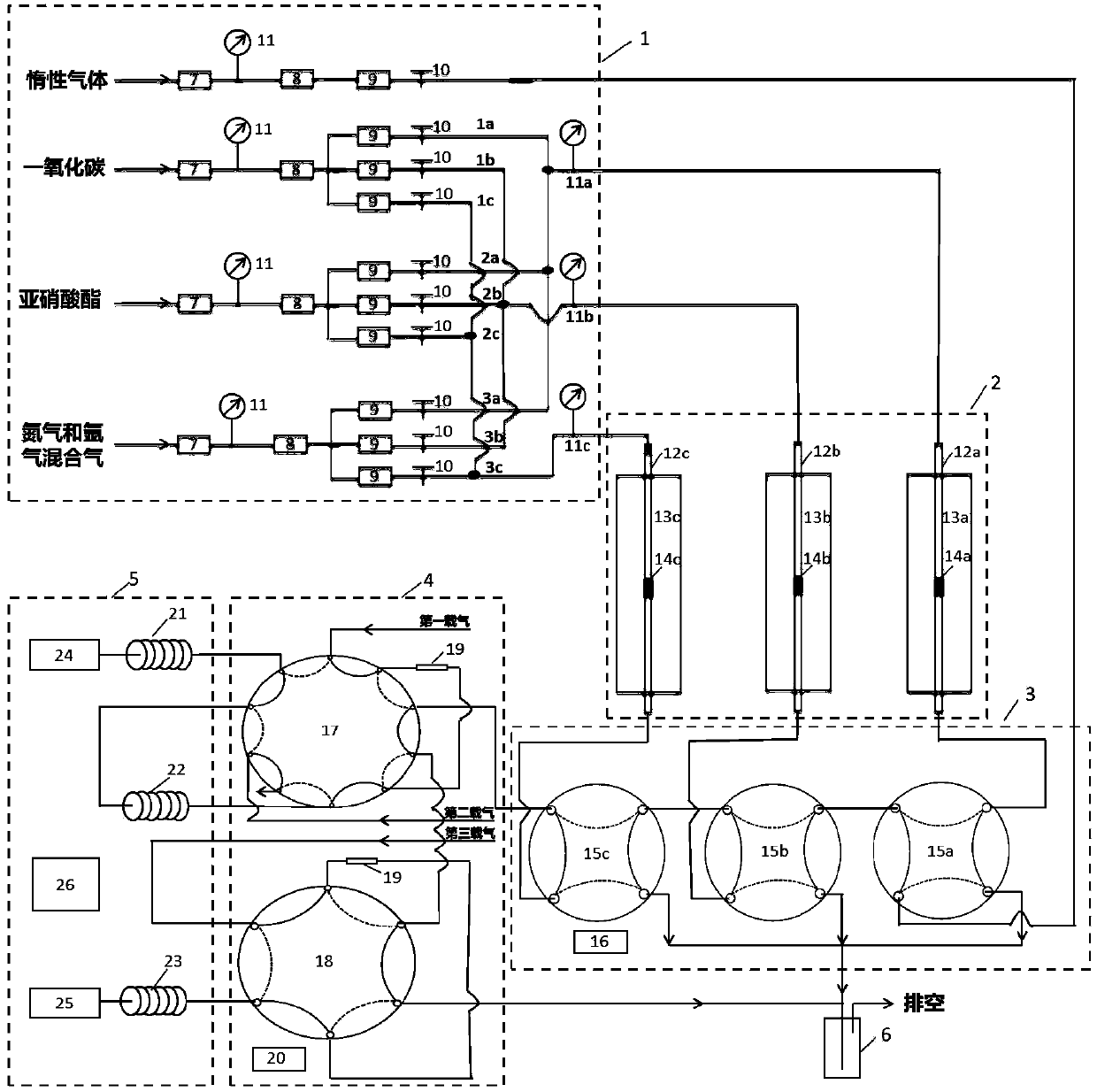

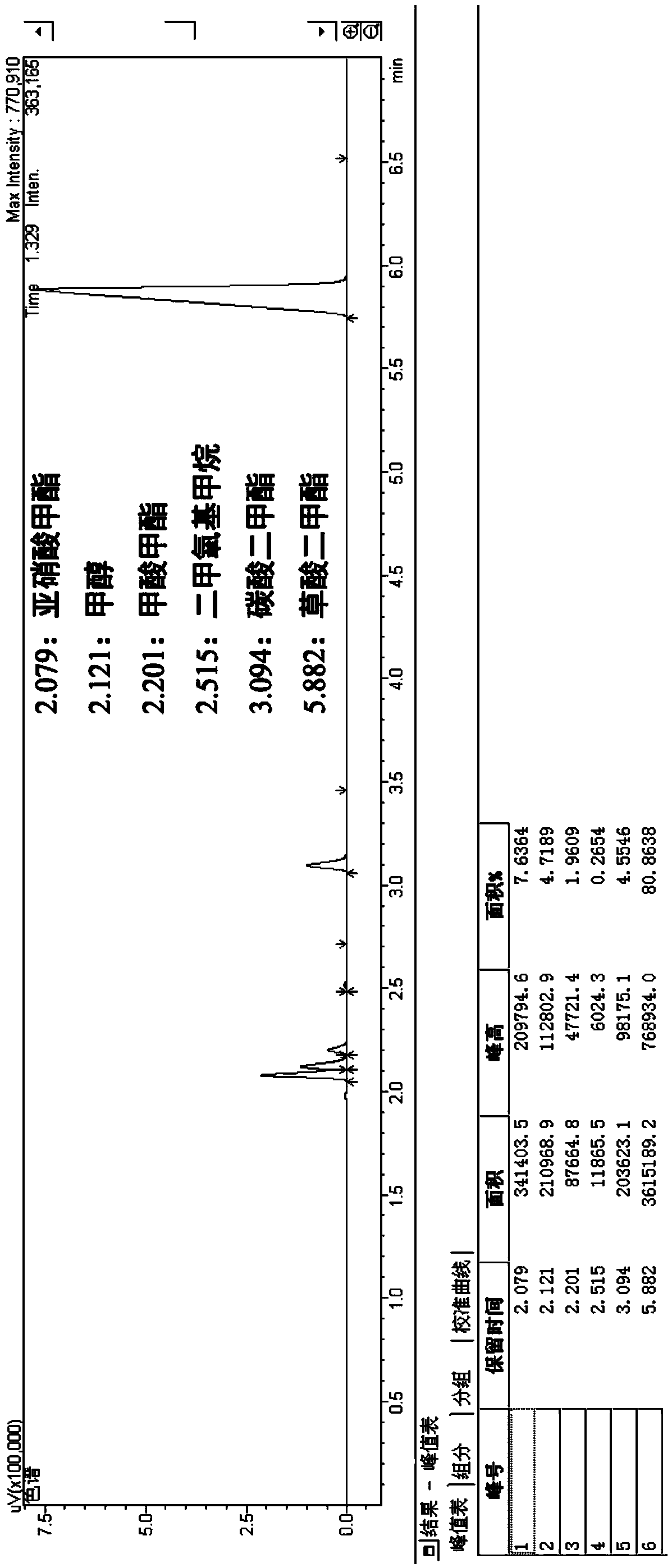

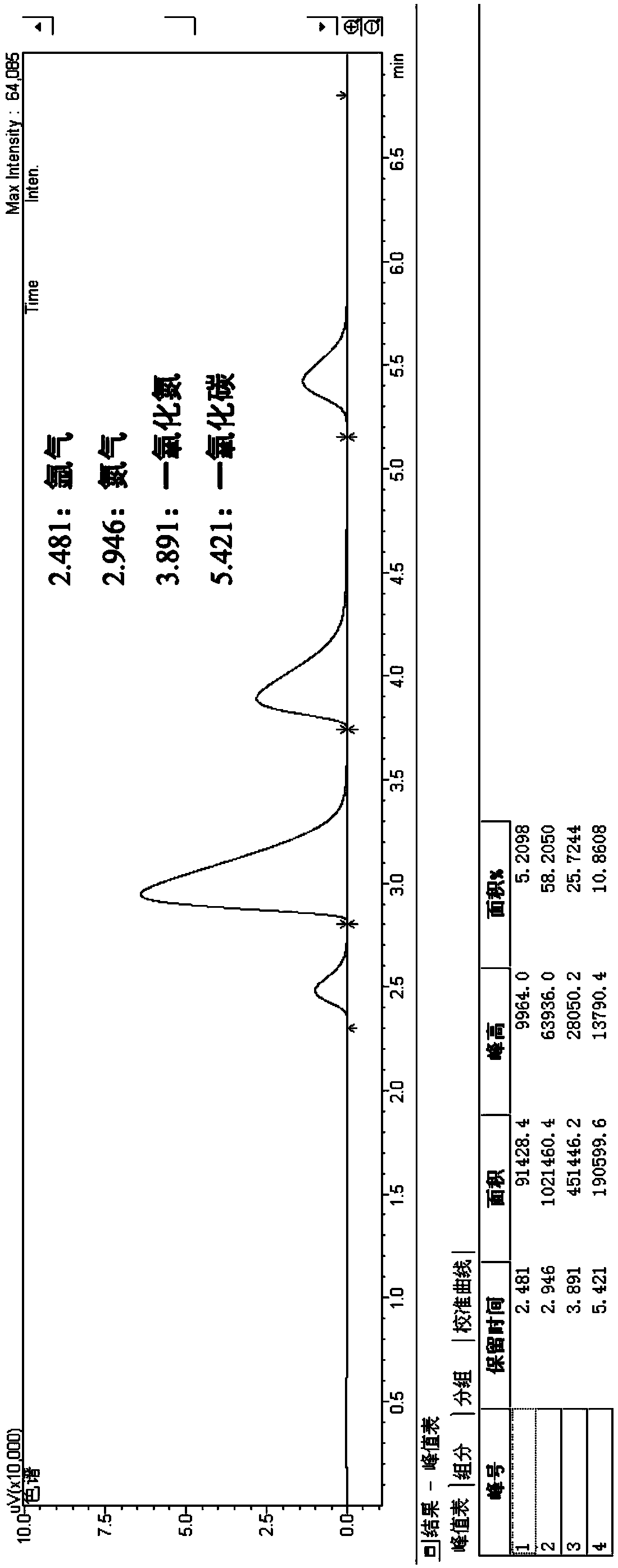

The invention discloses a device for evaluating a catalyst during preparation of oxalate through three-channel automatic CO gas phase oxidative coupling and a method for evaluating a catalyst by using the device. The device comprises a gas control pipeline system (1), a fixed bed reaction system (2), a four-way valve system (3), a multi-ported valve system (4), a dual-channel gas chromatography system (5) and a product absorbing tank (6), wherein the gas control pipeline system (1) comprises one path of inert gas purging pipeline, one path of carbon monoxide gas pipeline, one path of nitrite ester gas pipeline and one path of nitrogen and argon mixed gas pipeline, the carbon monoxide gas pipeline, the nitrite ester gas pipeline and the nitrogen and argon mixed gas pipeline are same, each path comprises a gas conveying pipeline, a pressure stabilizing valve (7), a pressure meter (11) and a current stabilizing valve (8) which are sequentially connected, a pipeline behind the current stabilizing valve (8) is divided into three branches, and each branch comprises a quantity and flow controller (9) and a switch valve (10). According to the device, three same or different catalysts can be simultaneously evaluated, the developing speed of the catalyst is greatly increased, all-component online real-time analysis of raw materials and products can be realized, and data is accurate and reliable.

Description

technical field The invention belongs to the technical field of catalyst development engineering, in particular to a catalyst evaluation device and a catalyst evaluation method for preparing oxalate by three-channel automatic CO gas-phase oxidation coupling. Background technique Ethylene glycol is an extremely important and strategic bulk chemical raw material. my country's annual demand is more than 10 million tons, while the production capacity is only more than 3 million tons. The contradiction between supply and demand is very prominent, and a large amount needs to be imported. Coal-to-ethylene glycol technology is of great significance for alleviating the contradiction between supply and demand of ethylene glycol in my country and for efficient and clean utilization of coal resources. CO gas-phase oxidative coupling to prepare oxalate is a key step in the conversion of inorganic CO to organic oxalate in coal-to-ethylene glycol technology. The reaction principle of C...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N30/02G01N30/06G01N30/68G01N35/00

Inventor 徐忠宁郭国聪彭思艳王志巧吕冬梅陈青松王明盛姚元根

Owner FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com