Industrial real-time data collecting system

A real-time data acquisition and industrial technology, applied in the fields of electrical digital data processing, structured data retrieval, special data processing applications, etc., can solve problems such as high cost, acquisition interface does not store real-time database, etc., to improve efficiency, reduce costs, The effect of reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

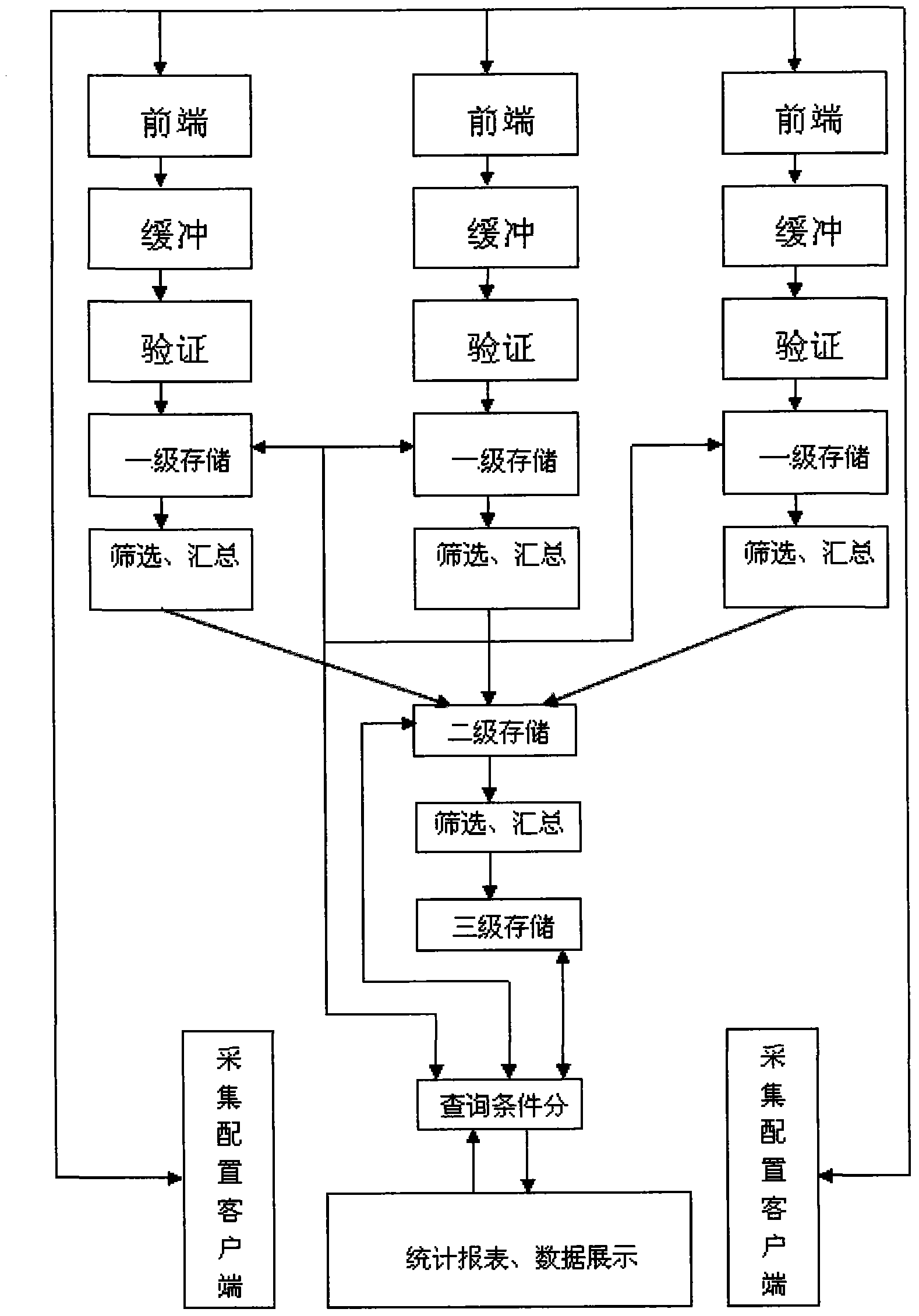

Method used

Image

Examples

Embodiment 1

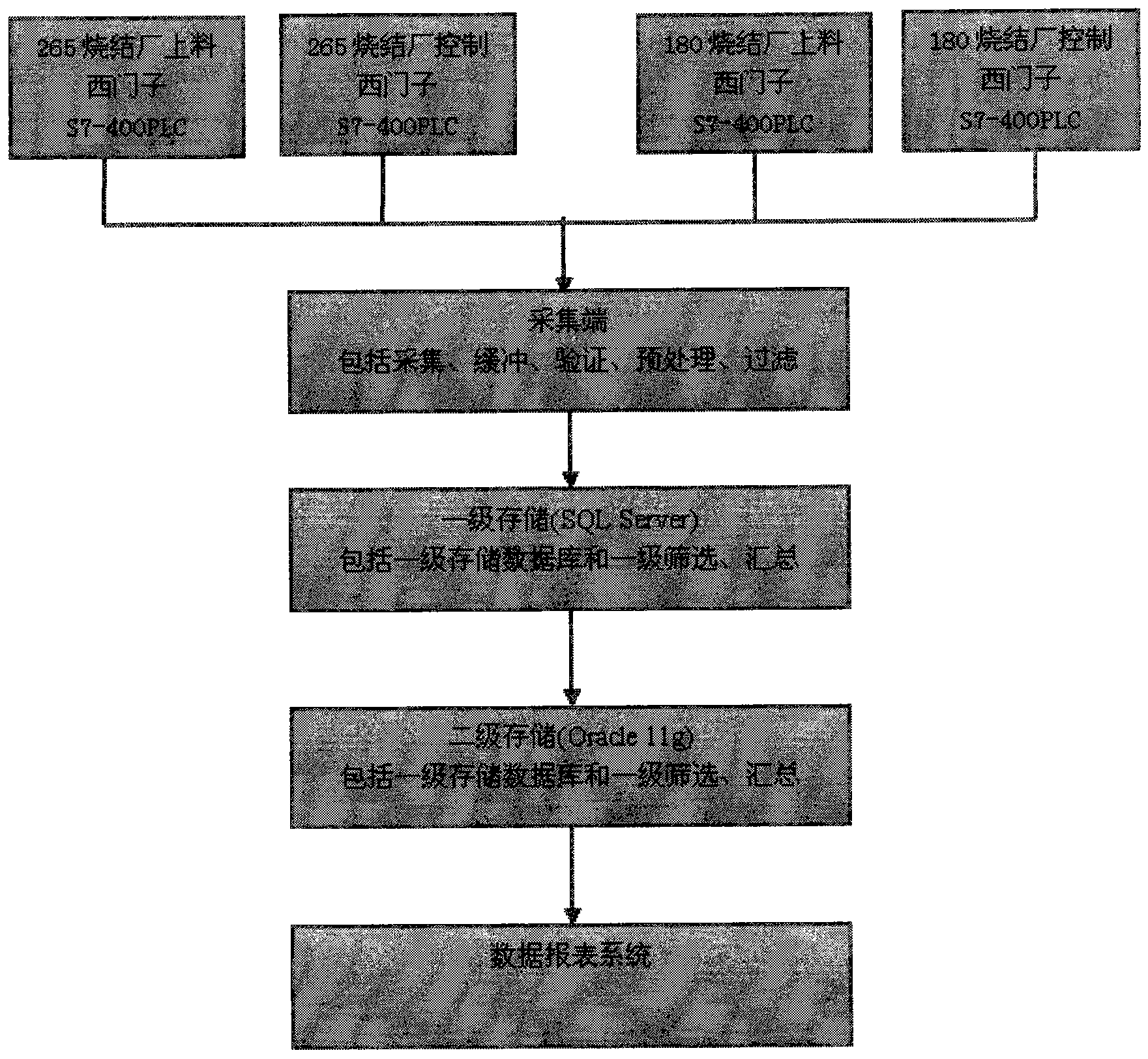

[0035] Example 1: figure 2 It is a block diagram of the raw material ratio and consumption data acquisition system of the sintering plant of Hebei Puyang Iron and Steel Co., Ltd. The acquisition front-end collects 265 sintering plant feeding data, 265 sintering plant control data, 180 sintering plant feeding data, 180 sintering plant control data, and transmits the collected data to the acquisition end through the Siemens S7-400PLC model acquisition front-end for buffering , verification, preprocessing and filtering, and store it in the first-level storage database (SQL Server), filter and summarize the data, store it in the second-level storage database, then filter and summarize the data, and read out the application from the client terminal in the data reporting system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com