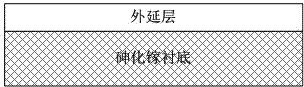

Method for stripping and transferring gallium arsenide based epitaxial layer

A gallium arsenide-based, lift-off transfer technology, applied in the field of semiconductor technology, to achieve the effect of not easy to wrinkle or break, good uniformity, and not easy to fragment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] ① Soak the gallium arsenide-based epitaxial wafer and glass slide in diluted hydrochloric acid (HCl) for 60 seconds, then rinse with deionized water, and put them in a spin dryer for drying.

[0039] ② Spin-coat the positive photoresist on the front surface of the GaAs-based epitaxial wafer, the rotation speed is 5000 rpm, and the spin-coating time is 90 seconds.

[0040] ③ Put the GaAs-based epitaxial wafer coated with positive photoresist facing up on the heating plate, the temperature of the hot plate is 110 degrees Celsius, and the baking time is 5 minutes.

[0041] ④Take the gallium arsenide-based epitaxial wafer from the hot plate and stack it with the front of the glass slide, fix it with a fixture and put it into a bonding machine for bonding. The bonding temperature is 200 degrees Celsius and the bonding time is 60 minutes.

[0042] ⑤ After bonding, thin the back of the gallium arsenide substrate of the gallium arsenide-based epitaxial wafer to about 100 micron...

Embodiment 2

[0048] ① Soak the gallium arsenide-based epitaxial wafer and glass slide in diluted hydrochloric acid (HCl) for 30 seconds, then rinse with deionized water, and put them in a spin dryer for drying.

[0049]② Spin-coat positive photoresist on the front surface of the GaAs-based epitaxial wafer, the rotation speed is 1000 rpm, and the spin-coating time is 60 seconds.

[0050] ③ Put the GaAs-based epitaxial wafer coated with positive photoresist facing up on the heating plate, the temperature of the hot plate is 100 degrees Celsius, and the baking time is 2 minutes.

[0051] ④Take the gallium arsenide-based epitaxial wafer from the hot plate and stack it with the front of the glass slide, fix it with a fixture and put it into a bonding machine for bonding. The bonding temperature is 180 degrees Celsius and the bonding time is 30 minutes.

[0052] ⑤ After bonding, thin the back of the gallium arsenide substrate of the gallium arsenide-based epitaxial wafer to about 100 microns, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com