Simple method for packaging and assembling non-refrigeration infrared detector TEC

A technology of uncooled infrared and infrared detectors, which is applied in the manufacture of electric solid-state devices, semiconductor devices, and final products. The process is simple and the effect of ensuring the vacuum life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

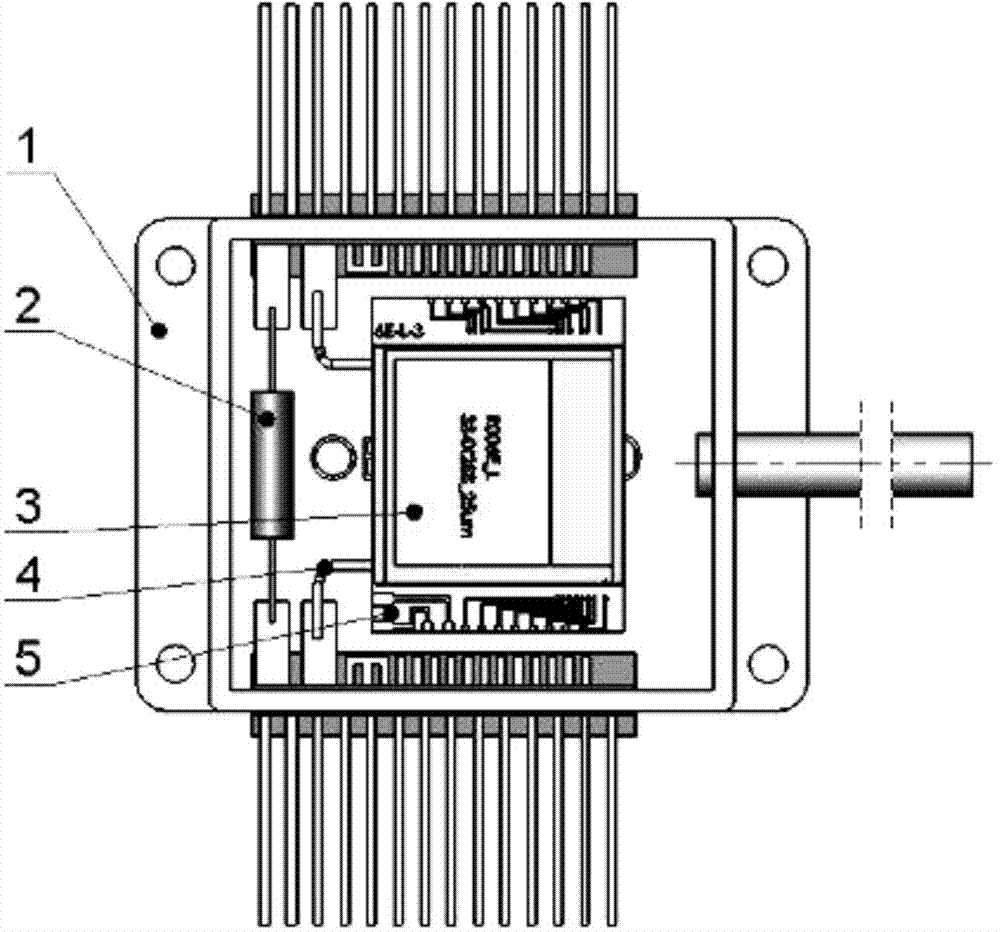

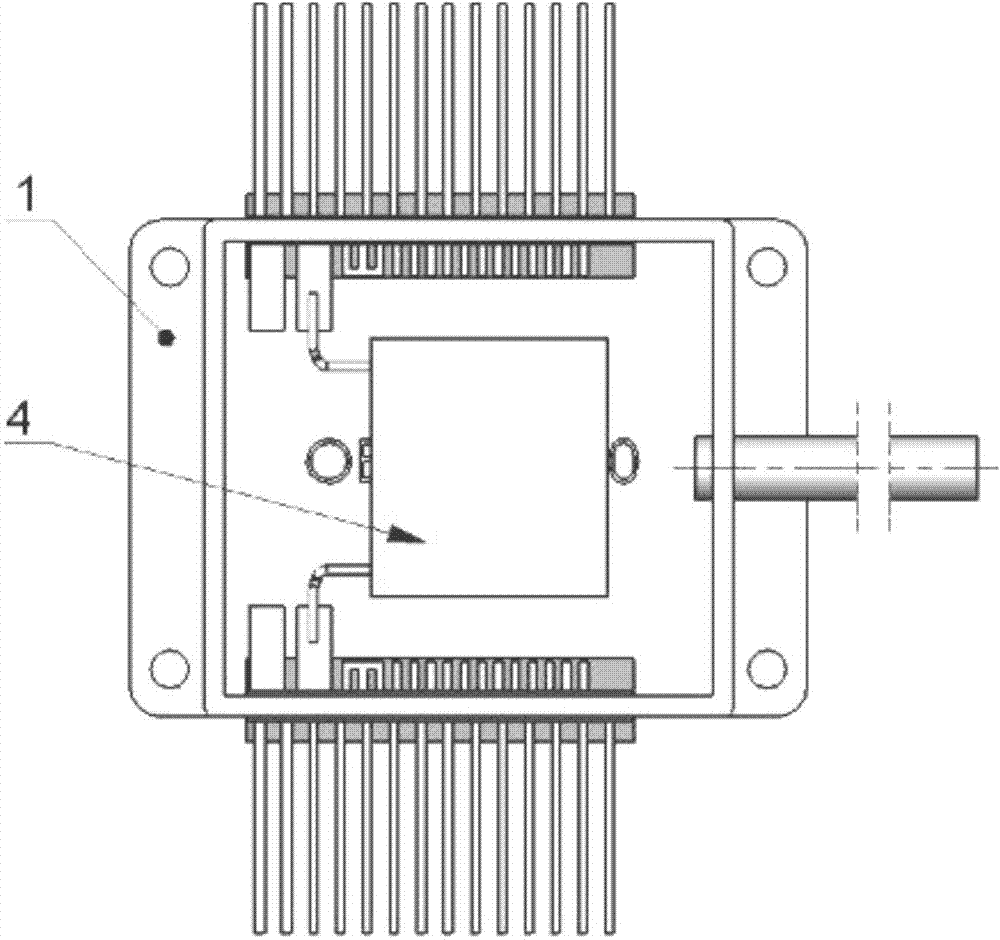

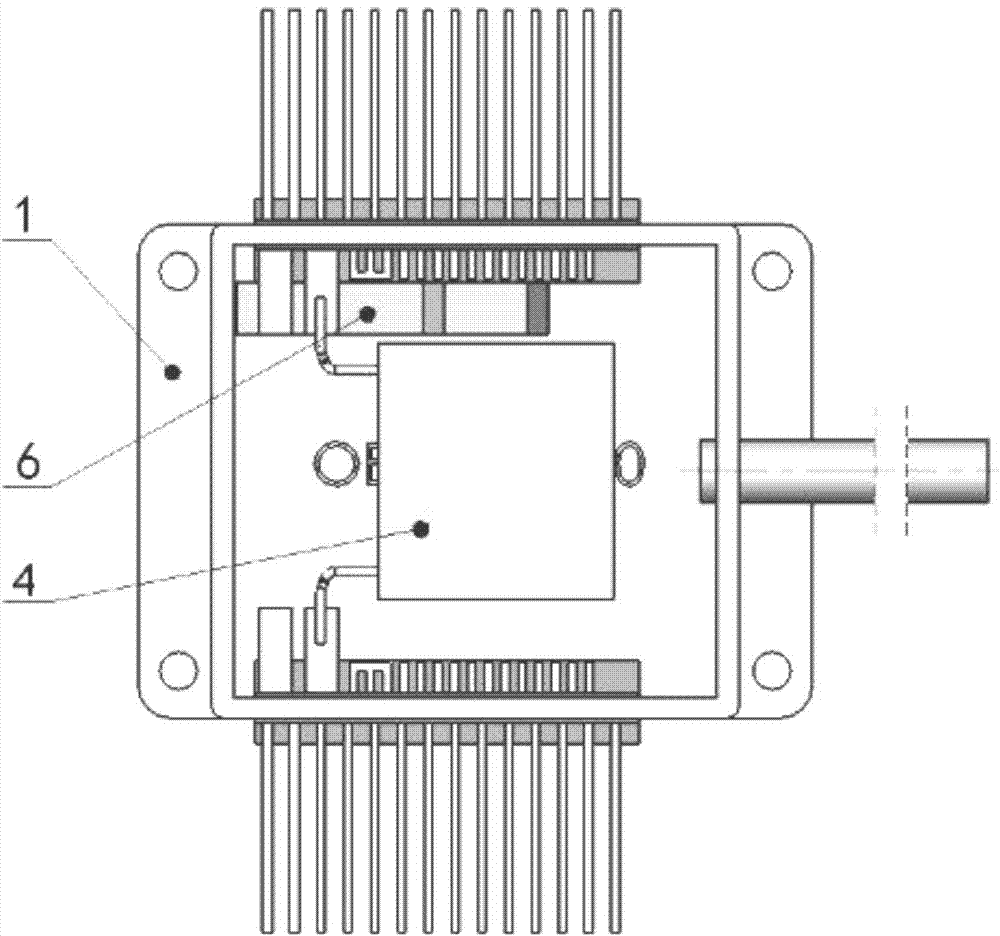

[0015] A simple method for packaging and assembling an uncooled infrared detector TEC. The infrared detector chip 3 is arranged on the semiconductor refrigerator 4, and is vacuum-sealed and packaged in the base 1 of the butterfly tube shell. The lead wire of the semiconductor refrigerator 4 and the butterfly tube The pins of the shell base 1 are welded by spot welding. The metal contact interface has contact resistance, and the contact resistance is larger than the metal body resistance. Spot welding is to melt the contact interface of metal parts by high current and weld them together. The spot welding process needs to form a large current loop, and the package shell has a small space, and it is impossible to directly clamp the TEC lead and the shell pin to form a large current loop. Therefore, a tooling is designed to hold the TEC pin of the shell, and click When welding, a large current loop can be formed through the base of the shell, and the base of the shell is relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com