Circuit board and manufacturing method

A manufacturing method and circuit board technology, which are applied in the directions of printed circuit components, electrical connection printed components, and electrical connection formation of printed components, etc., can solve problems such as increased alignment difficulty, excessive aspect ratio, and increased printed circuit board wiring area. , to achieve the effect of improving alignment ability and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The circuit board of the embodiment of the present invention and its manufacturing method are described below. However, it can be easily understood that the embodiments provided in the present invention are only used to illustrate the making and use of the present invention in a specific way, and are not intended to limit the scope of the present invention. Furthermore, the same reference numerals are used in the drawings and descriptions of the embodiments of the present invention to denote the same or similar components.

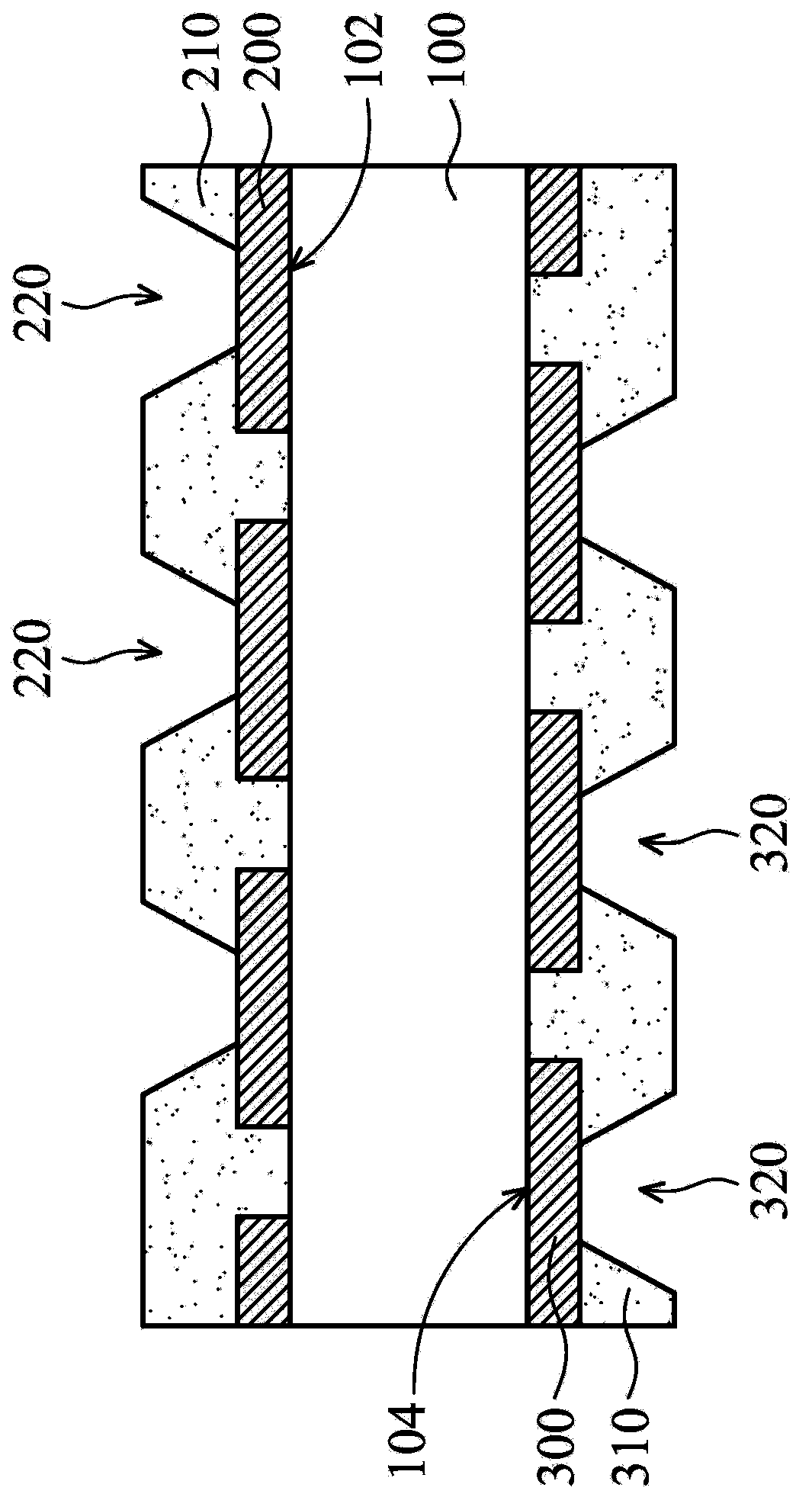

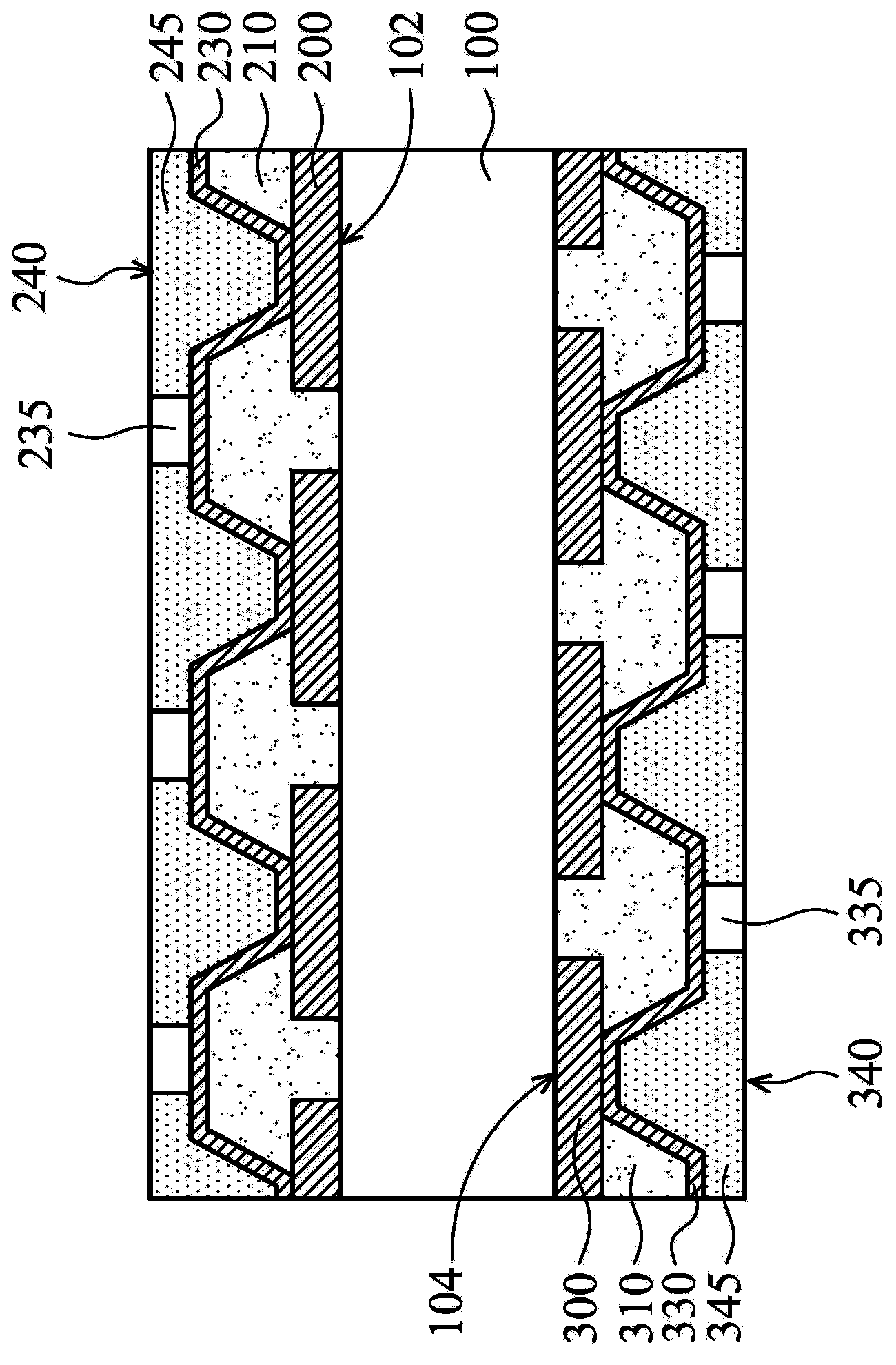

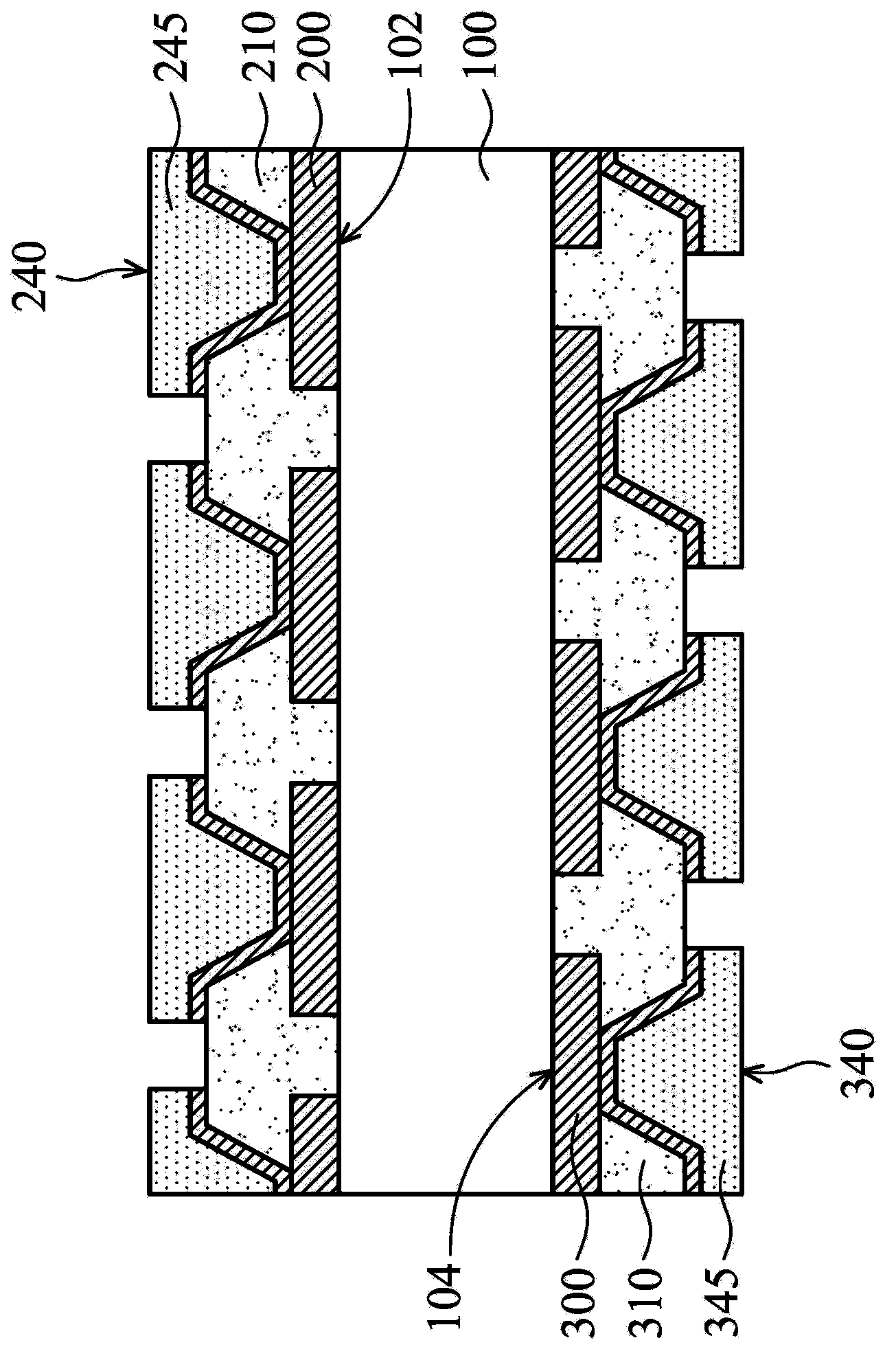

[0042] Please refer to Figure 6 , which shows a schematic cross-sectional view of a circuit board according to an embodiment of the present invention. In this embodiment, the circuit board includes a substrate 100, a plurality of first conductive blocks 200, a first insulating layer 210, a plurality of first conductive components 240, a second insulating layer 250, a second conductive component 280, a plurality of A second conductive block 300 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com