Method and Mechanism for Automatic Alignment of Flexible Circuit Board

A flexible circuit board and automatic alignment technology, which is applied in the direction of assembling printed circuits with electrical components, can solve the problems of high flatness requirements of raw materials, low connection efficiency, and high throwing rate, so as to reduce the throwing rate, improve flatness, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

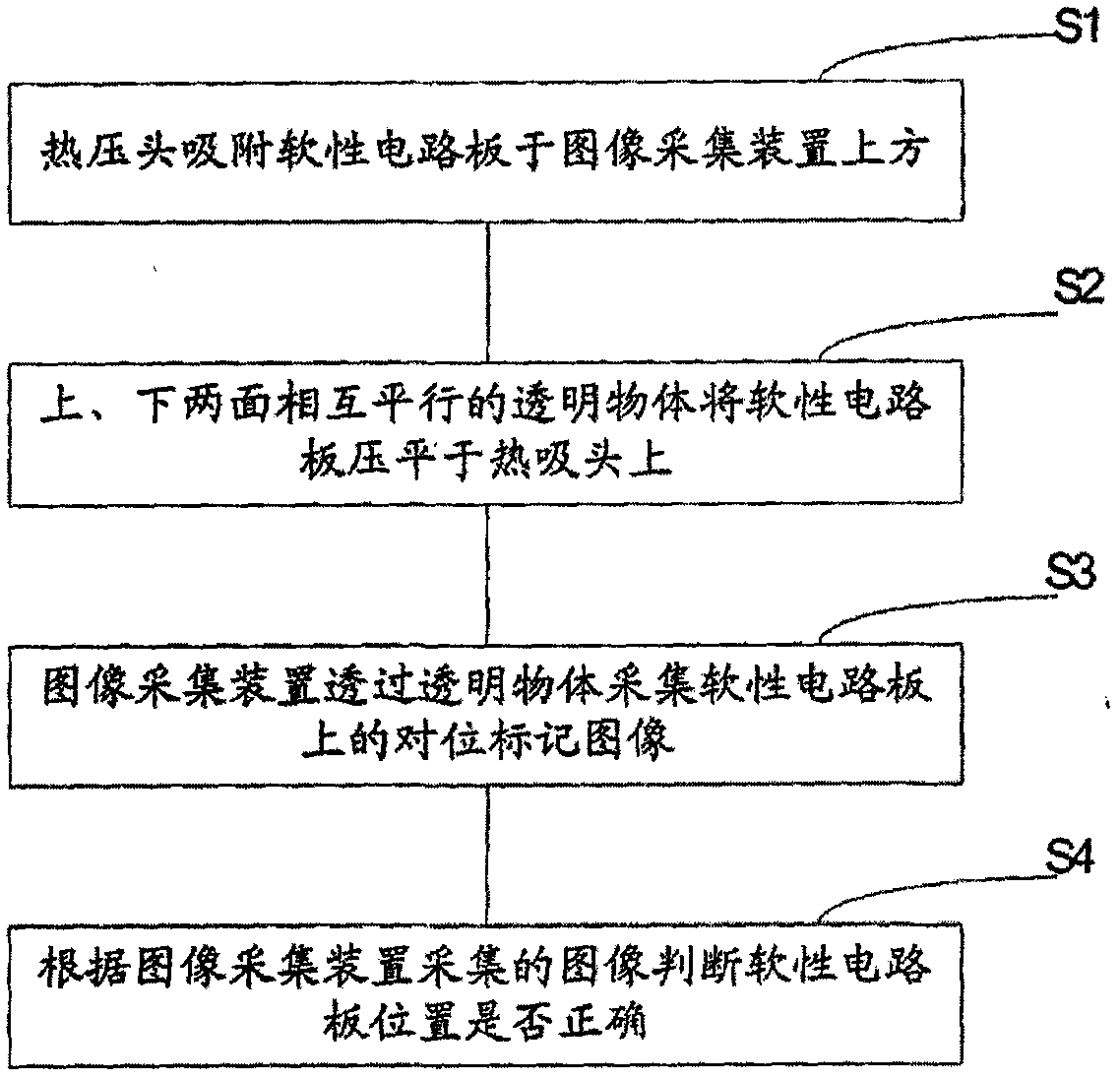

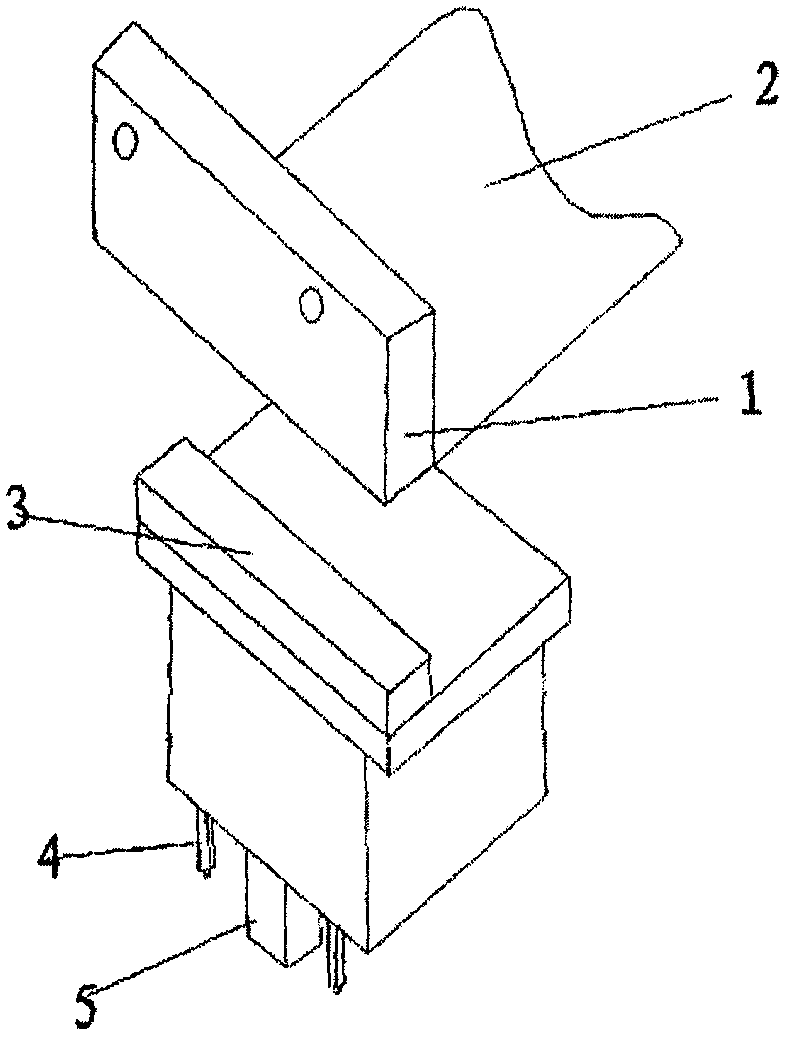

[0025] refer to figure 1 , the embodiment of the present invention proposes a method for automatic alignment of flexible printed circuit boards, including:

[0026] Step S1. The thermal head absorbs the flexible circuit board above the image acquisition device. There is a vacuum suction cup on the thermal pressure head, and the vacuum suction cup is connected to the vacuum pump. On the adsorption end of the thermal head;

[0027] Step S2, the upper and lower sides of the transparent solid are parallel to each other, and the flexible circuit board is flattened on the heat suction head; the upper and lower sides of the transparent solid are parallel to each other. The two sides are parallel to each other, which means that the upper and lower surfaces of the transparent solid are planes. Only the planes can better flat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com