Self-synchronizing translation elliptical vibrating screen with three shock excitation motors

A technology of exciting motor and elliptical vibration, applied in the direction of filter screen, mobile filter element filter, grille, etc., can solve the problems of harsh conditions and difficult implementation of actual design, and achieve improved transportation speed, easy manufacturing and installation, and maintenance. Easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

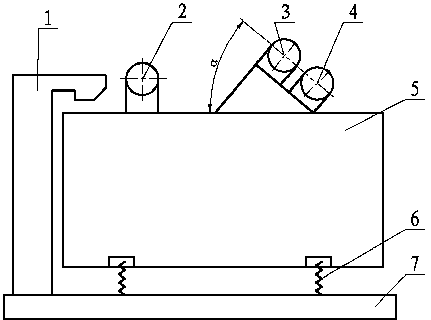

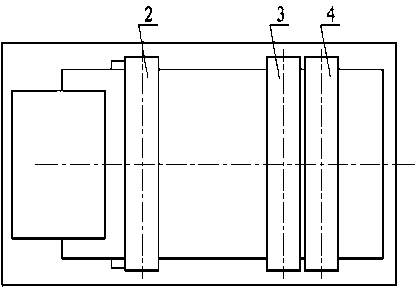

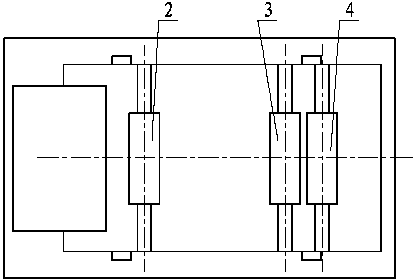

[0012] Such as figure 1 , figure 2 , image 3 As shown, the self-synchronous translational elliptical vibrating screen with three excitation motors of the present invention is composed of a feed hopper 1, a first vibration motor 2, a second vibration motor 3, a third vibration motor 4, a screen box 5, a vibration isolation Spring 6 and base 7 form. The screen box 5 is supported on the base 7 by the vibration isolation spring 6 . The axes of the second excitation motor 3 and the third excitation motor 4 are installed parallel to each other, the plane where the axes are located and the horizontal plane form a certain angle α, and the same eccentric mass moment is used to rotate in the opposite direction at a constant speed, and the generated excitation The resultant force of the inertial force is a linear excitation force. The vertical line of the second vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com