Method for preparing multi-walled carbon nano tube

A technology of multi-walled carbon nanotubes and reaction chambers, applied in the direction of carbon nanotubes, nanocarbon, nanotechnology, etc., can solve the problem of low reaction temperature, difficulty in removing attached or coated carbon nanotubes, and poor graphitization degree of carbon nanotubes and other problems, to achieve the effect of high yield, convenient and quick preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation of a method for preparing multi-walled carbon nanotubes provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

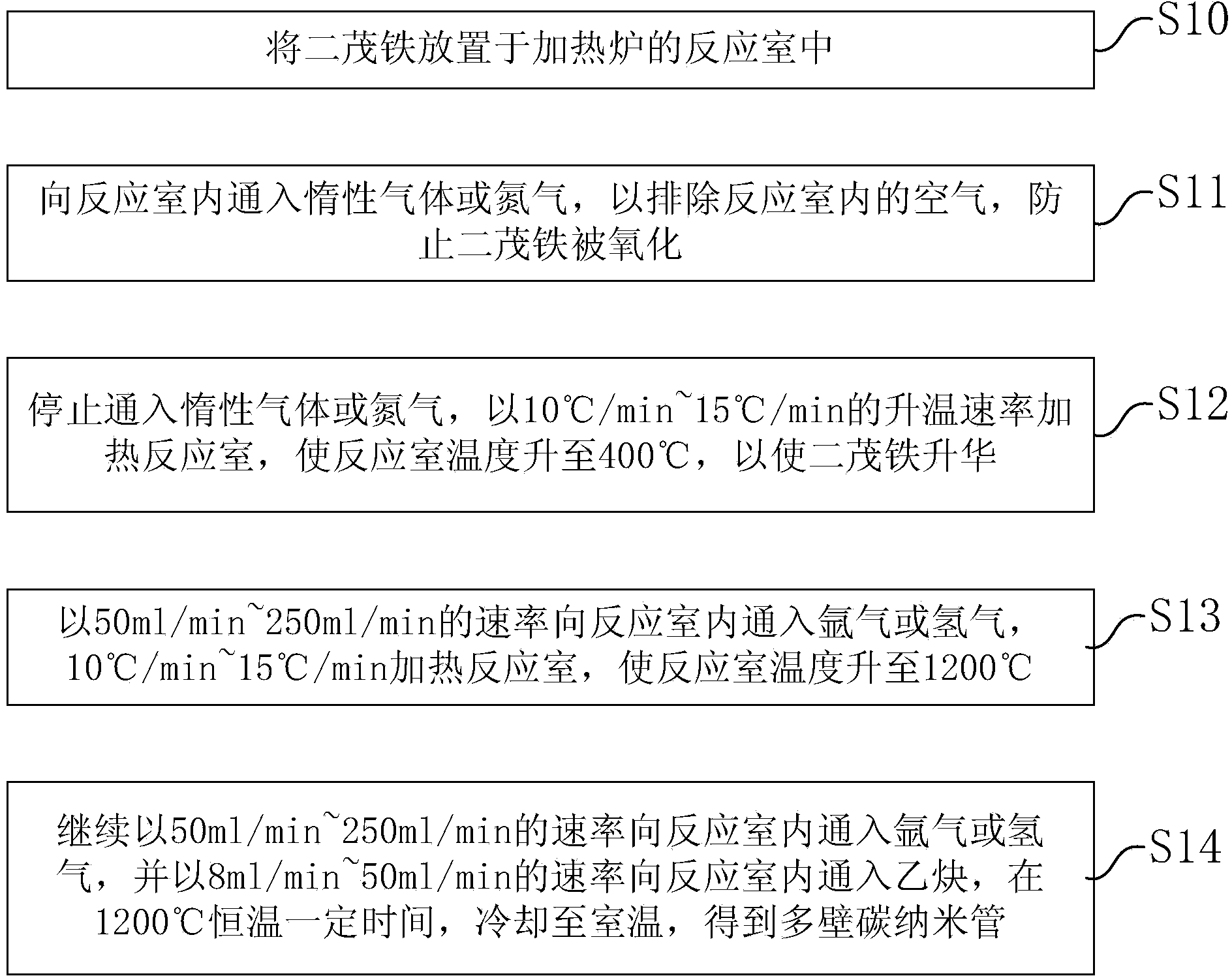

[0038] see figure 1 , the preparation method of multi-walled carbon nanotubes of the present invention comprises the following steps:

[0039] Step S10, placing the ferrocene in the reaction chamber of the heating furnace. The heating furnace is a program-controlled heating furnace, which can control the heating rate. In this specific embodiment, a porcelain boat containing 200 mg of ferrocene is put into a quartz tube, and then the quartz tube is put into a heating furnace, and the quartz tube is a reaction chamber.

[0040] In this step, the preparation method of the ferrocene comprises the following steps:

[0041] (a) Thermally decompose cyclopentadiene dimer at 163°C to 200°C to generate cyclopentadiene monomer. The amount of cyclopentadiene dimer is determined ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com