Integral rapid carbonizing treatment technology for municipal waste

A technology for municipal garbage and garbage, which is applied in the petroleum industry, special carbonization, coking ovens, etc. It can solve the problems of high cost, long process cycle, and complex separation of products in biological treatment, and achieve fast heating rate and high heat utilization rate. , the effect of large heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

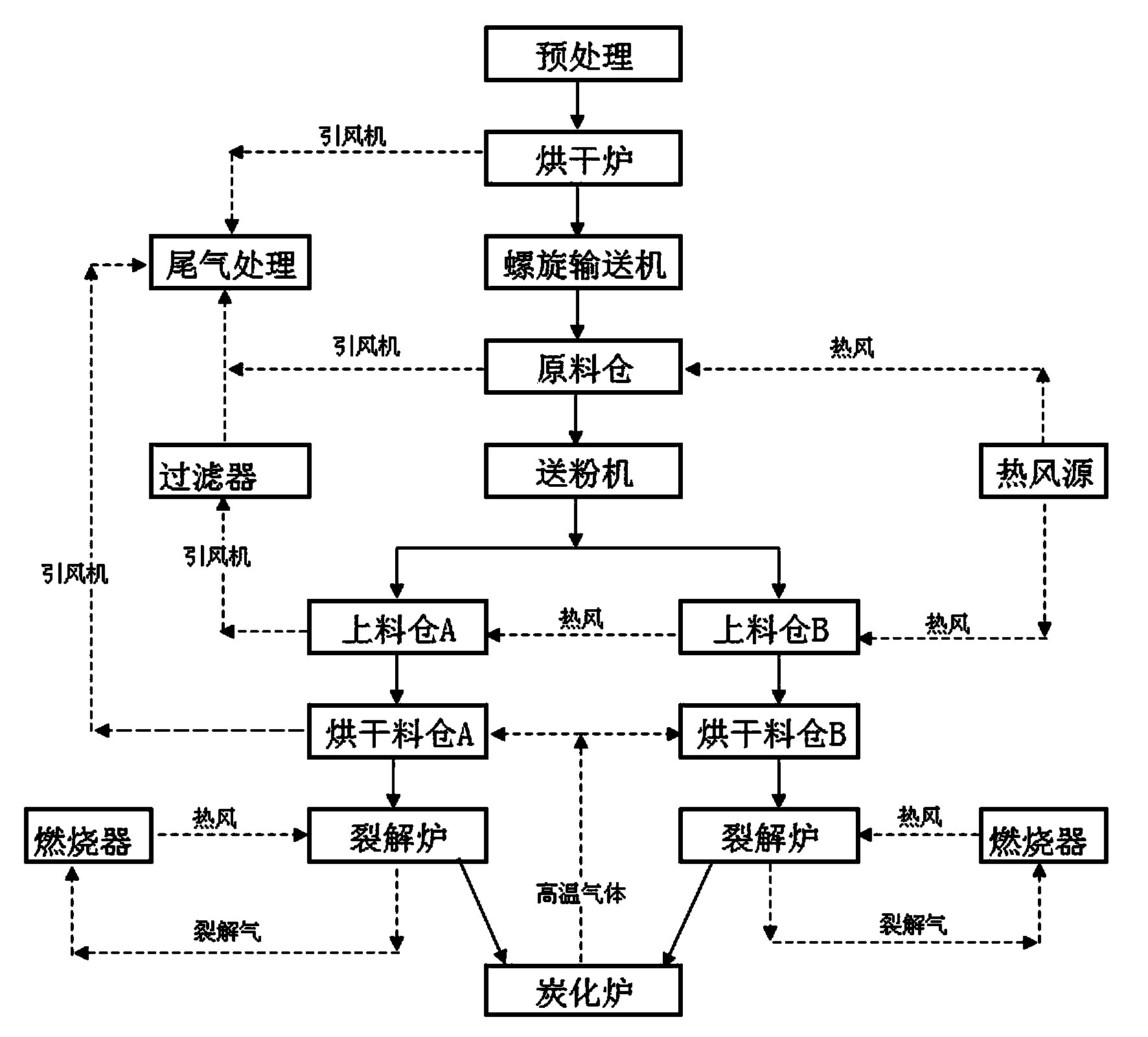

[0030] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

[0031] The process for integrated rapid carbonization treatment of urban waste includes the following steps:

[0032] (1) Garbage pretreatment: sort and recycle the construction waste such as stones and metal objects in the belt-treated waste, and use a crusher to crush the waste into particles with a particle size of 5-50mm to be processed;

[0033] (2) Removal of garbage liquid: send the crushed garbage into the distribution bin of the drying furnace, and the garbage is evenly distributed from the distribution bin to the conveyor belt in the drying furnace, and the garbage on the conveyor belt can be regulated and polymerized in the furnace Under the heating hood, it is quickly heated and dehydrated. The vaporized water in the garbage is pumped out by the induced draft fan and sent to the tail gas treatment station. The dehyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com