Scaling rig

A technology for prying trolleys and cabs, which is applied in the fields of mining prying trolleys and mining machinery, can solve problems such as difficulty in improving operation efficiency, hidden dangers in production operations, and parking risks, and achieve convenient and easy parking operation. Low cost of use and maintenance, simple and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

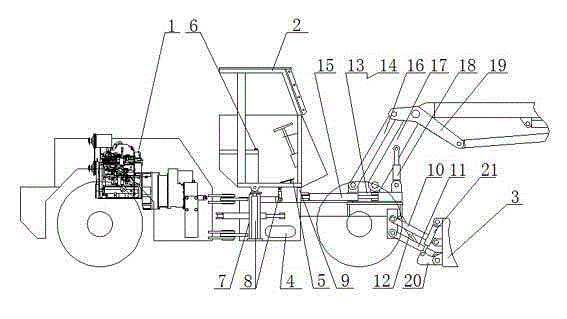

[0012] Depend on figure 1 As shown, the prying trolley includes a frame 1, a cab 2, a shovel 3, a gas-liquid hybrid parking mechanism, a cab lifting and pitching mechanism, a shovel translation mechanism, a swing mechanism of a working device, The translational mechanism and support mechanism of the working arm, the gas-liquid hybrid parking mechanism includes an air pump, an air storage tank 4, a foot valve 5, a pneumatic switch valve 6, an oil-pneumatic brake booster pump and a wheel hydraulic brake pump. The air pump communicates with the air storage tank 4 through the air pipe, and the air storage tank 4 uses the air pipe to communicate with the No. 1 air port of the pneumatic switch valve 6 through the foot valve 5. The No. 2 air port of the pneumatic switching valve 6 is connected with the oil-air brake booster pump through the air pipe, and the oil-air brake booster pump is respectively connected with the wheel hydraulic brake pump through the oil pipe; and three lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com