Energy-saving tunnel reduction kiln

A tunnel and kiln car technology, applied in the field of roasting equipment and smelting, can solve the problems of changing the one-way single-lane car entry mode, difficult to control pressure and atmosphere, and large floor space, achieving small footprint, flexible location selection, The effect of low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

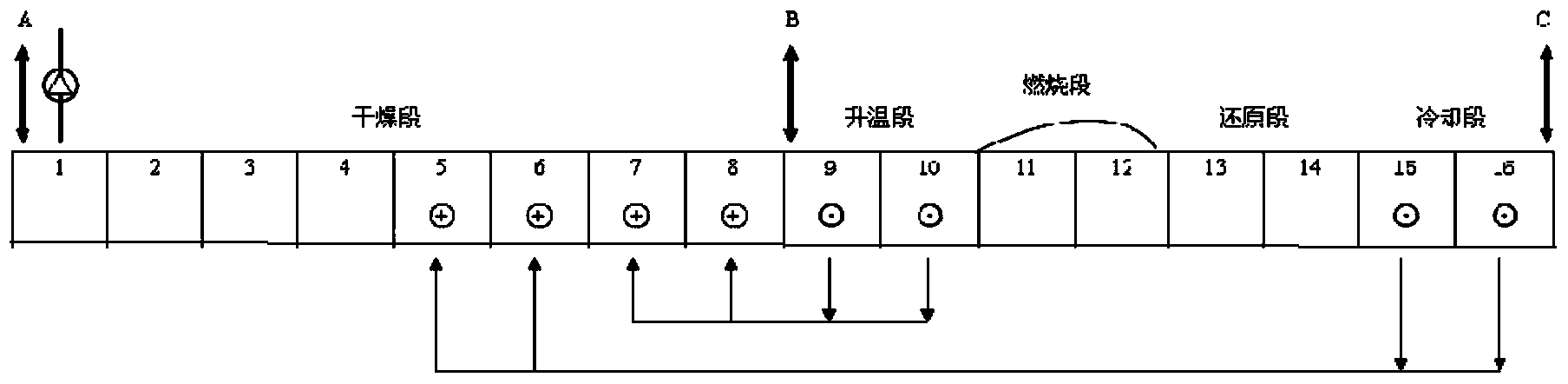

[0029] as attached figure 1 As shown, an energy-saving tunnel reduction kiln is built, wherein the tunnel reduction kiln is sequentially set up as a drying section, a heating section, a combustion section, a reducing section, and a cooling section; there is a ventilation outlet at the top of the entrance of the drying section, and the entrance of the heating section There is a heat source inlet at the top, and an air inlet is opened at the top of the outlet of the cooling section; the bottom of the cooling section communicates with the bottom of the middle position of the drying section, and the bottom of the heating section communicates with the bottom near the exit of the drying section. The length of the drying section is equivalent to the total length of the heating section, combustion section, reduction section and cooling section.

[0030] A track is laid at the bottom of the reduction kiln in the energy-saving tunnel, and a kiln car is loaded on the track, and coal powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com