Color film substrate, manufacturing method of same and display panel

A color filter substrate, display panel technology, applied in static indicators, instruments, computing and other directions, can solve the problems of low signal-to-noise ratio, high power consumption, poor picture quality of the display panel, etc., to improve the signal-to-noise ratio, increase the distance, the effect of reducing parasitic capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

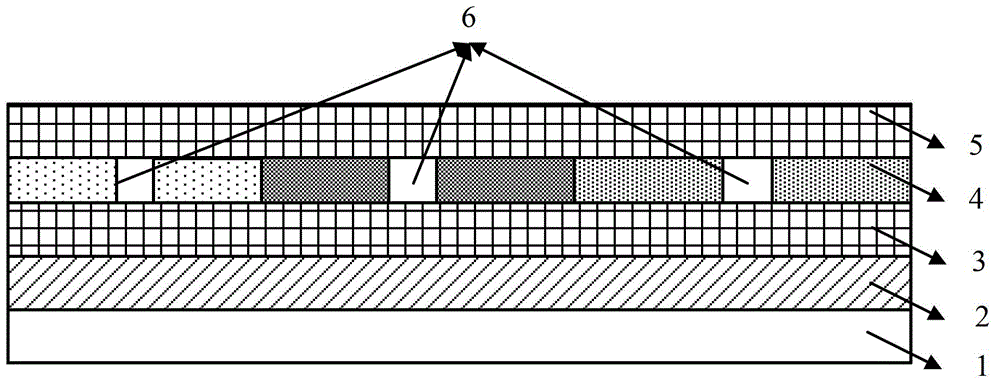

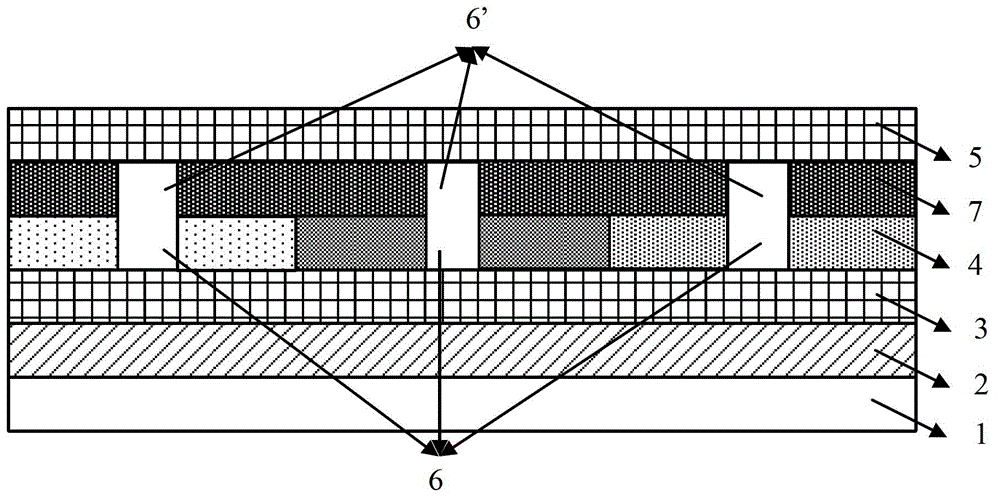

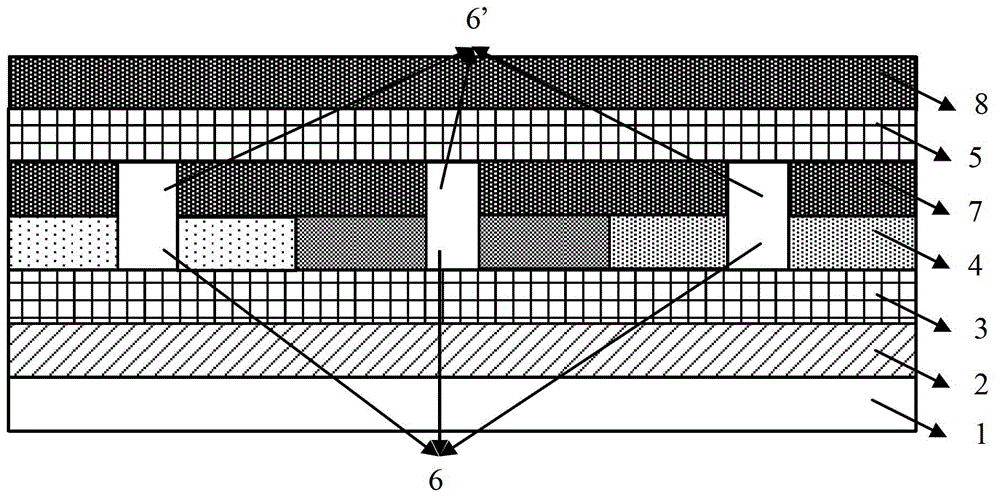

[0025] In order to solve the problems of low signal-to-noise ratio, high power consumption, and poor picture quality of the embedded touch display panel in the prior art. In the embodiment of the present invention, the first insulating layer is added between the RGB color resist layer and the second conductive film layer in the color filter substrate, thereby increasing the distance between the first conductive film layer and the second conductive film layer, This structure effectively reduces the parasitic capacitance of the color filter substrate, and improves the signal-to-noise ratio of the in-cell touch function display panel using the color filter substrate; and, during the production process of the color filter substrate, the first insulating layer can effectively Block the damage to the RGB color-resist layer caused by conductive substances and photoresist stripping solution when making the second conductive film layer, so that there is no color difference and damage in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com