Resistance trigger type vacuum arc ion source device

A trigger type, vacuum arc technology, applied in the field of ion source, can solve the problems of complex power source, increase the complexity of ion source structure, volume weight and cost, and achieve the goal of improving reliability, increasing design difficulty and reducing contact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

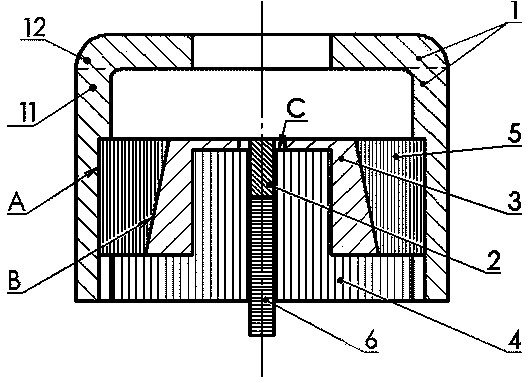

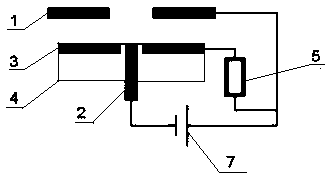

[0029] Such as figure 1As shown, the resistance-triggered vacuum arc ion source device includes an anode 1, a cathode 2, a trigger electrode 3, a cathode-trigger electrode insulator 4, a trigger resistor 5, and a cathode fixed conductive joint 6 connected to the lower end of the cathode 2. The above-mentioned anode 1 It consists of a hollow cylindrical first part of the anode 11 and a ring-shaped anode 12 connected to the upper end of the anode support 11. The above-mentioned trigger resistor 5, trigger electrode 3, cathode-trigger electrode insulator 4 and cathode 2 are arranged in sequence from outside to inside. In the anode support 11, the outer edge of the ring-shaped anode 12 is connected to the upper end of the anode support 11. In practical applications, the outer edge of the ring-shaped anode 12 and the anode support 11 are preferably made of the same material. The anode support 11 is also Can be discharged with cathode 2. The cathode fixing conductive joint 6 has tw...

Embodiment 2

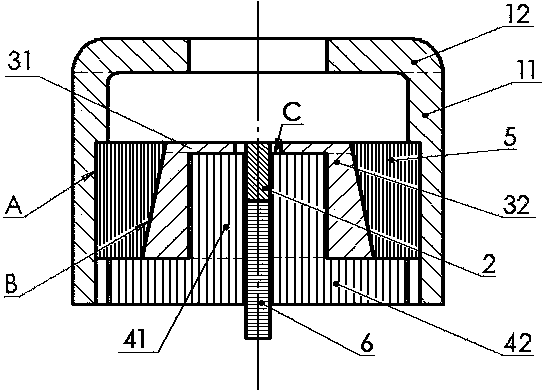

[0034] Such as figure 2 As shown, this embodiment is further improved on the basis of Embodiment 1. The above-mentioned cathode 2 and cathode fixed conductive joint 6 are both cylindrical, which are arranged on the central axis of the anode 1, and the above-mentioned cathode-trigger electrode insulating member 4 is covered Outside the cathode 2 and the cathode fixed conductive joint 6, and the upper end surface of the cathode-trigger insulator 4 is lower than the upper end surface of the cathode 2;

[0035] The above-mentioned trigger pole 3 is composed of a trigger pole support 32 coated on the outside of the cathode-trigger pole insulator 4 and a ring-shaped trigger pole 31 connected to the upper end of the trigger pole support 32. The trigger pole support 32 and the ring-shaped trigger pole 31 are also preferably The same material is integrally formed, the lower end surface of the annular trigger electrode 31 is also connected to the upper end surface of the cathode-trigge...

Embodiment 3

[0040] On the basis of Embodiment 2, in this embodiment, the cathode-trigger insulator 4 is composed of a first insulator 41 and a second insulator 42 located at the lower end of the first insulator 41, the first insulator 41 and the second insulator The insulators 42 are all hollow cylinders with the same inner diameter and coincident central axes, and the outer diameter of the first insulator 41 is smaller than that of the second insulator 42; the first insulator 41 and the second insulator 42 are preferably integrally manufactured from the same material , the inner peripheral surface of the first trigger pole 32 is connected to the outer peripheral surface of the first insulator 41, the above-mentioned annular trigger pole 31 is connected to the upper end of the first insulator 41; the lower end surface of the trigger resistor 5 and the trigger pole 3 are connected on the upper end surface of the second insulating member 42 .

[0041] In this embodiment, the inner periphera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com