Humidifier for fuel cells and fuel cell stack with humidifier

A fuel cell and humidifier technology, applied in the direction of fuel cells, fuel cell additives, fuel cell grouping, etc., can solve problems such as unsatisfactory humidification effects, and achieve the effects of saving manufacturing costs, reducing costs, and low material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] air self-humidification

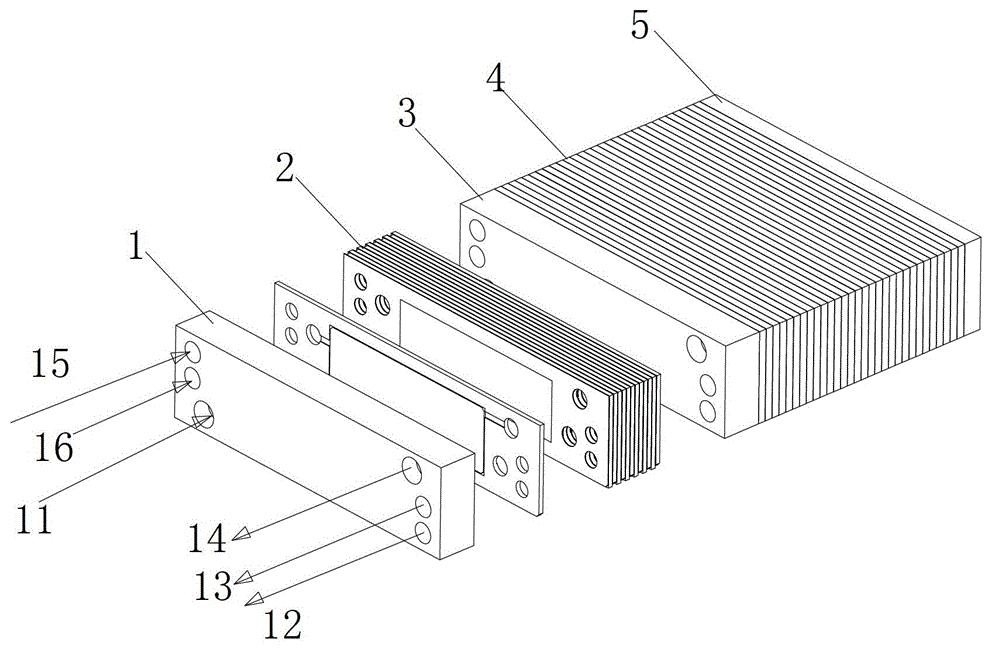

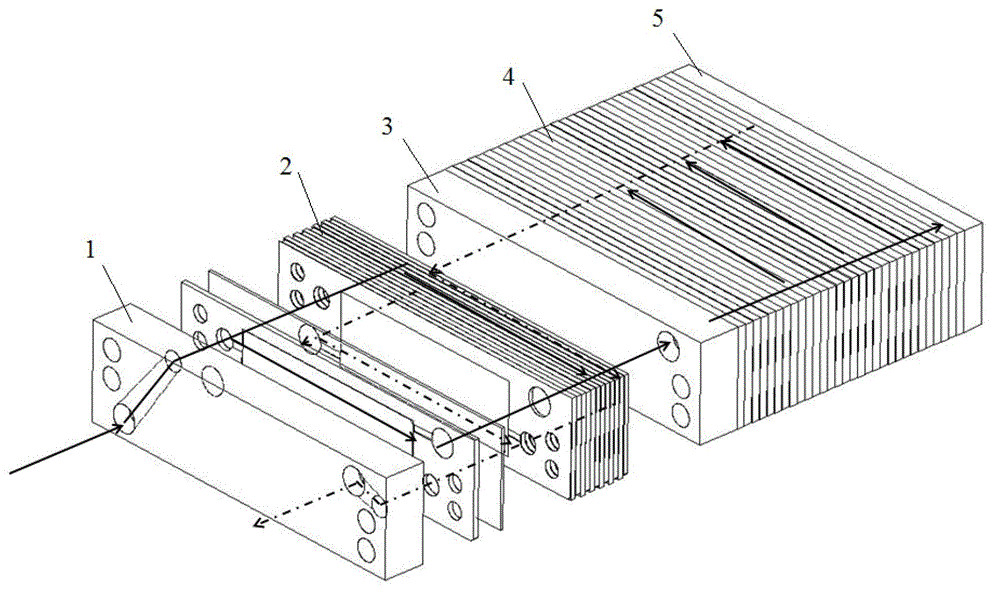

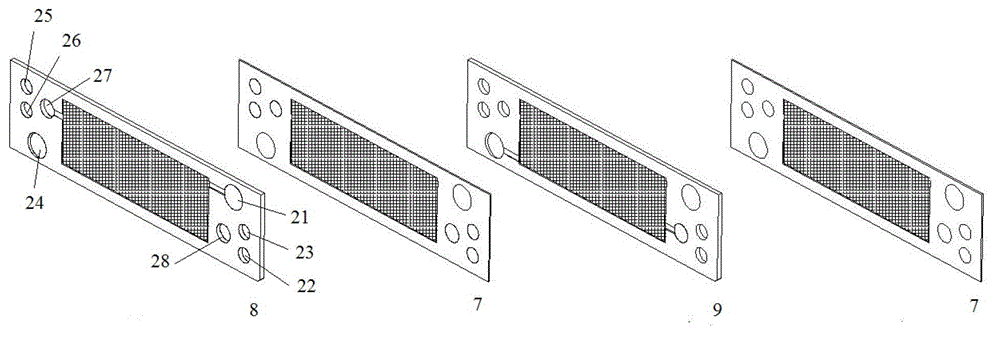

[0028] Such as Figure 1-2 As shown, a humidifier for a fuel cell and a fuel cell stack with the humidifier, the fuel cell includes a front end plate 1, a humidifier 2, a rear end plate 3, a stack 4 and a bottom plate 5 connected in sequence, and the humidifier It is composed of a number of humidification units 6 and humidification membrane components 7 interposed between the front end plate and the rear end plate. The humidification unit 6 is composed of a dry panel 8, a humidification membrane component 7 and a wet panel 9 in sequence. The two humidification units A humidification membrane module 7 (such as image 3 As shown), the front end plate 1, rear end plate 3, dry panel 8 and wet panel 9 are provided with three inlets and three outlets: oxidant inlet 21, fuel inlet 25, coolant inlet 26, oxidizer outlet 24, fuel outlet 22, Coolant outlet 23, also set up two inlet and outlet branch ports on the dry panel and the wet panel, air intake b...

Embodiment 2

[0037] Hydrogen Humidification

[0038] The structure of the electric stack is as in Example 1, a humidifier is set, only the total hydrogen inlet is exchanged with the total air inlet, and the total hydrogen outlet is exchanged with the total air outlet, the inlet branch on the humidifier The port is connected to the total hydrogen gas inlet on the front panel, and the oxidant inlet 21 on the dry panel 8 is used as the hydrogen gas inlet. All the other are with embodiment 1.

Embodiment 3

[0040] Simultaneous humidification of air and hydrogen

[0041] Such as image 3 As shown, the gas to be humidified is hydrogen and air, and there are two humidifiers, one as a hydrogen humidifier 28 and the other as an air humidifier 29 .

[0042] Described hydrogen humidifier 28 is identical with the humidifying unit structure of air humidifier 29, only will be used as the position of total hydrogen gas inlet 15 on hydrogen humidifier 28, as total air inlet 11 on air humidifier 29, And the position where the hydrogen humidifier 28 is used as the total hydrogen gas outlet 12 is used as the total air outlet 14 on the air humidifier 29 .

[0043] After the hydrogen flows in from the front plate, it flows in from the inlet branch of the hydrogen humidifier for humidification, and then flows into the power stack through the total hydrogen inlet set on the air humidifier to react; the air flows in from the front plate and passes through the hydrogen humidifier. The set total air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com