A kind of preparation method of electronic device or circuit diagram

A technology of electronic devices and circuit diagrams, which is applied in the manufacture of printed circuits, electrical components, printed circuits, etc., can solve the problems of high ink adhesion, increased production costs, and pattern deviation, achieving low cost, saving time, and improving The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Embodiment: metal palladium is used as catalyst particles, polystyrene is used as fixing agent particles to prepare electronic device method

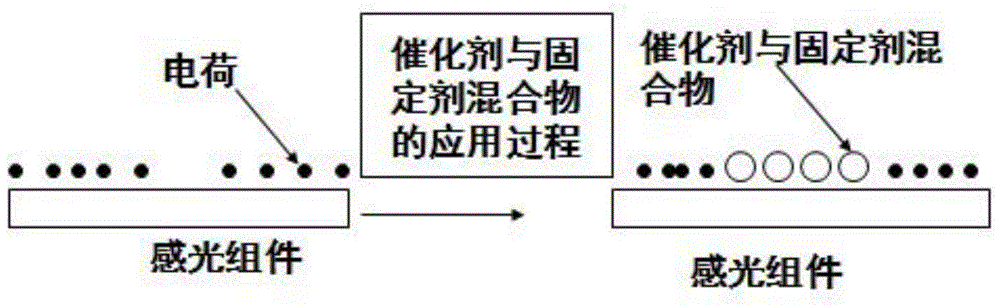

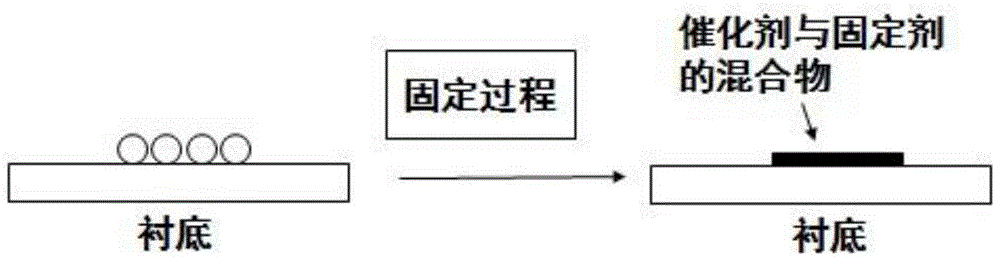

[0032] Prepare the mixture of catalyst particles and fixative particles: metal palladium and polystyrene are ground into fine particles by ball mill respectively, wherein the particle diameter of metal palladium after grinding is 10nm (here metal palladium can be 1nm after grinding. to 1mm), polystyrene is ground into small particles with a particle size of 1um (wherein the particle size of polystyrene particles after grinding can range from 0.1um to 10um), then the small metal palladium and and The polystyrene is mixed according to the specific gravity of 100:5, and the mixture is placed in a device, and the device can charge the above mixture.

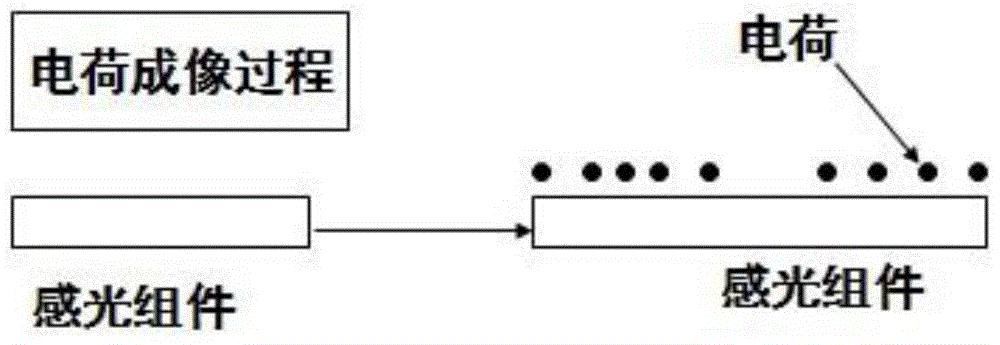

[0033] Imaging on photosensitive components: such as figure 1 As shown, the pattern of the electronic device or circuit diagram that needs to be prepared is drawn on the computer, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com