Special aqueous grinding fluid for hard alloy and preparation method thereof

A technology of cemented carbide and grinding fluid, which is applied in the preparation of special water-based grinding fluid for cemented carbide grinding and in the field of water-based grinding fluid for cemented carbide grinding, which can solve the problem of reducing the mechanical resistance of cemented carbide parts. Problems such as impact force and service life, health hazards of operators, and shedding of tungsten carbide particles on the surface can achieve the effects of inhibiting the growth of bacteria, less environmental pollution, and excellent lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

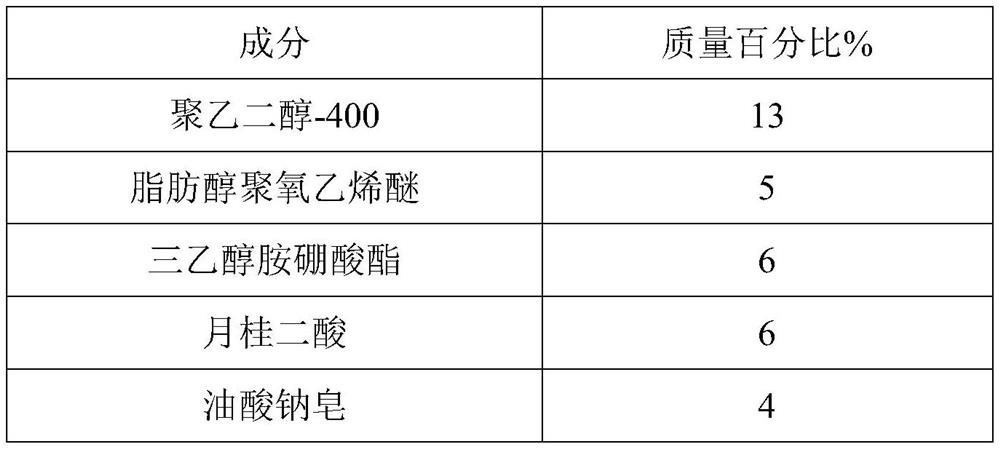

[0029] A special water-based grinding fluid for cemented carbide, its proportioning is shown in Table 1

[0030] Table 1 Distribution ratio of each group

[0031]

[0032]

[0033] A kind of preparation method of aqueous grinding fluid special for cemented carbide, its concrete steps are as follows:

[0034] a) Weigh the corresponding materials according to the above materials and mass percentage.

[0035] b) Add polyethylene glycol-400, fatty alcohol polyoxyethylene ether, triethanolamine borate, lauric acid, sodium oleate soap, benzotriazole, silicone defoamer and water into the reaction kettle Stir and mix at 40°C for 30 minutes to 1 hour to obtain mixed component A;

[0036] c) When the temperature of the mixing component A in the reaction kettle drops to room temperature (20-30°C), add sodium hydroxide and anionic polyacrylamide to the mixing component A and stir and mix for 30min-1h to obtain the product.

[0037] Apply the above products to the immersion experi...

Embodiment 2

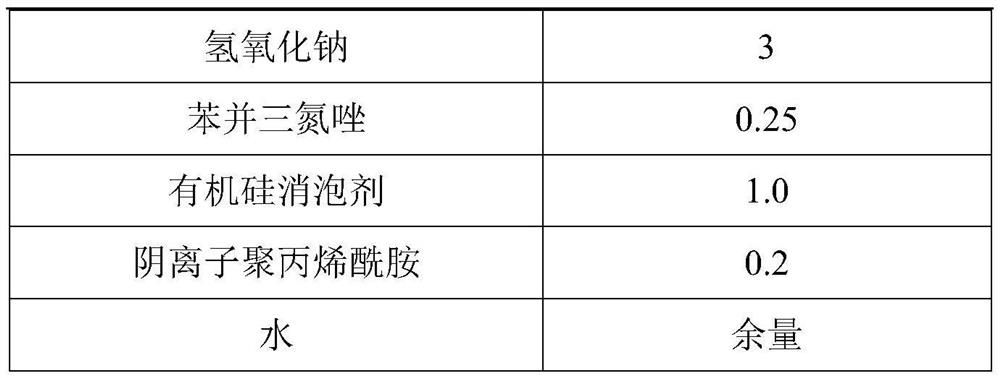

[0040] A special water-based grinding fluid for cemented carbide, its proportion is shown in Table 2

[0041] Table 2 Distribution ratio of each group

[0042]

[0043]

[0044] A kind of preparation method of aqueous grinding fluid special for cemented carbide, its concrete steps are as follows:

[0045] a) Weigh the corresponding materials according to the above materials and mass percentage.

[0046] b) Add polyethylene glycol-600, fatty alcohol polyoxyethylene ether, triethanolamine borate, lauric acid, sodium oleate soap, methyl benzotriazole, silicone defoamer and water into the reactor Stir and mix at 80°C for 30min to 1h to obtain mixed component A;

[0047] c) When the temperature of the mixing component A in the reaction kettle drops to room temperature (20-30°C), add sodium hydroxide and anionic polyacrylamide to the mixing component A and stir and mix for 30min-1h to obtain the product.

[0048] Apply the above product to the immersion test of the YG6 bran...

Embodiment 3

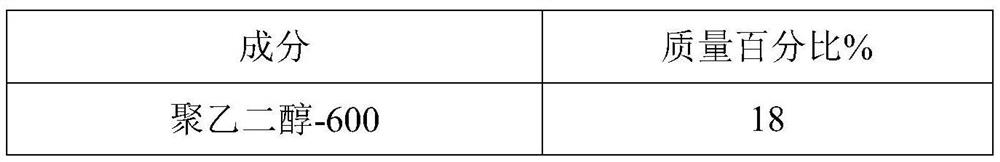

[0050] A special water-based grinding fluid for cemented carbide, its proportion is shown in Table 3

[0051] Table 3 distribution ratio of each group

[0052]

[0053]

[0054] A kind of preparation method of aqueous grinding fluid special for cemented carbide, its concrete steps are as follows:

[0055] a) Weigh the corresponding materials according to the above materials and mass percentage.

[0056] b) Add polyethylene glycol-400, alkylphenol polyoxyethylene ether, triethanolamine borate, lauric acid, sodium oleate soap, methyl benzotriazole, silicone defoamer and water to react Stir and mix in the kettle at 60°C for 30min to 1h to obtain mixed component A;

[0057] c) When the temperature of the mixing component A in the reaction kettle drops to room temperature (20-30°C), add sodium hydroxide and anionic polyacrylamide to the mixing component A and stir and mix for 30min-1h to obtain the product.

[0058] Apply the above product to the immersion test of the YG6 br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com