Real-time monitoring device and method for hammer cracking of artificial diamond press machine and judgment method for hammer cracking

An artificial diamond, real-time monitoring technology, applied in the application of ultra-high pressure process, etc., can solve the problems of inability to judge the crack of the hammer head, prone to misoperation, etc., to reduce losses, avoid misjudgment, and facilitate replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

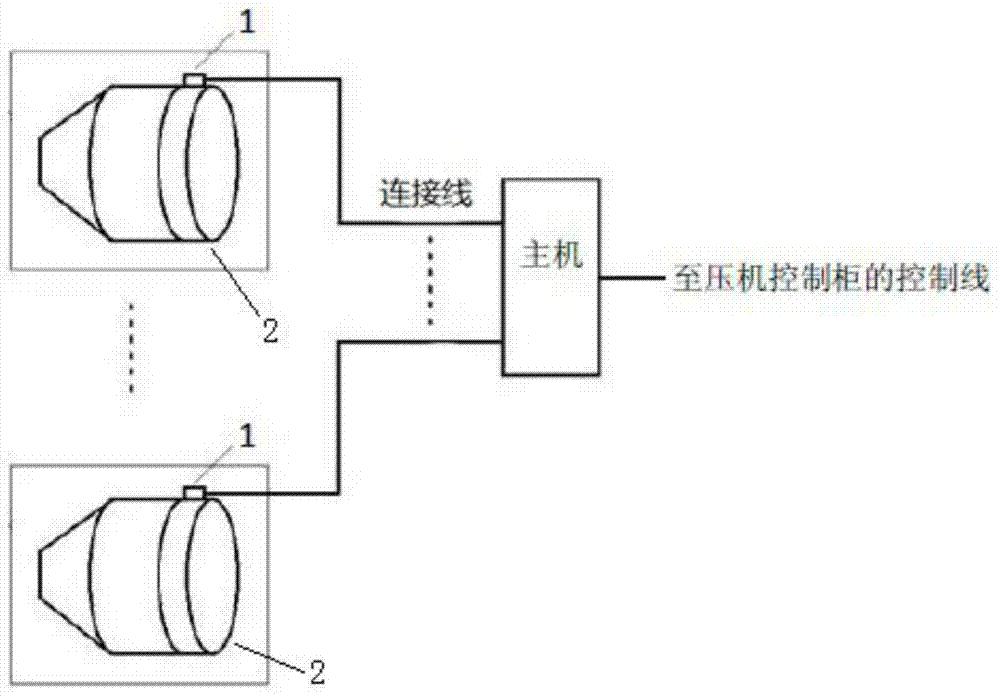

[0037] Such as figure 1 As shown in the figure, the real-time monitoring device for the split hammer of a synthetic diamond press includes a main engine, one-to-one detection components 1 installed on the six anvil rings 2 of the diamond press anvil, one-to-one connections between the main engine and the six detection components 1 Lines, control lines connecting the host machine and the press control cabinet.

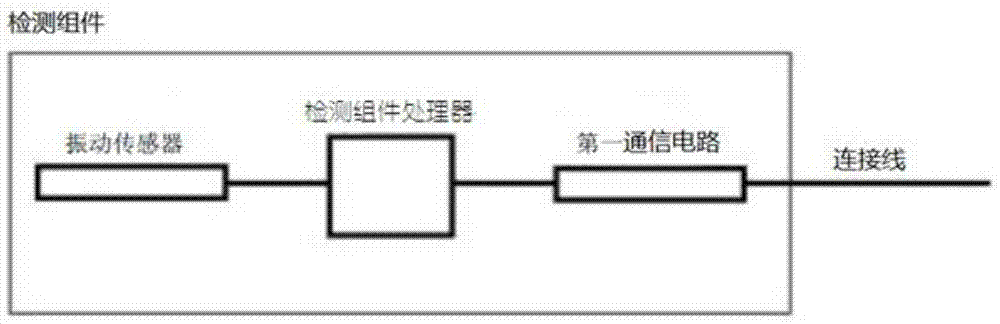

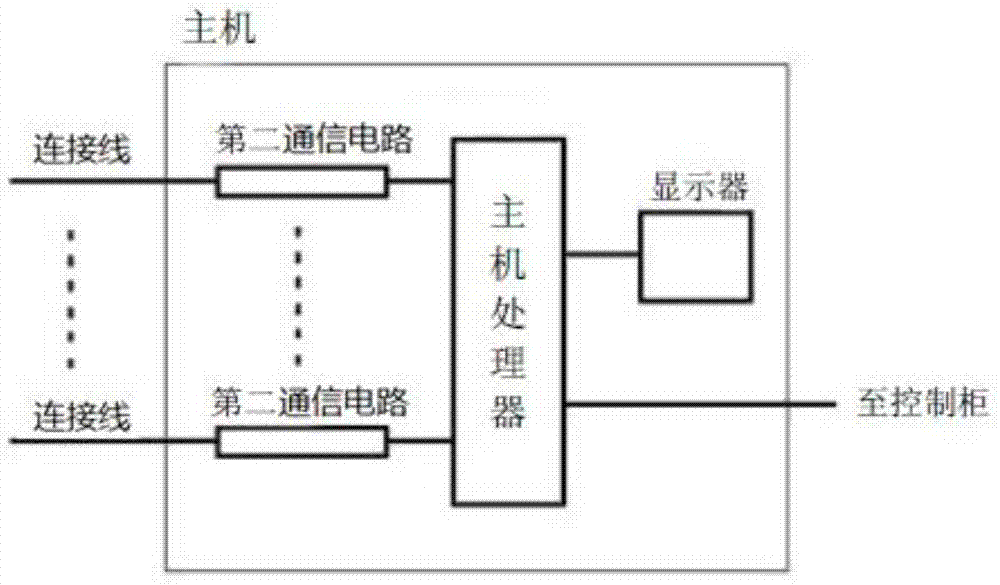

[0038] Such as figure 2 As shown, the detection component 1 is composed of a vibration sensor (such as BMA180), a detection component processor (such as PIC18F45K50), and a first communication circuit connected in sequence. Such as image 3 As shown, the host includes 6 second communication circuits and a host processor (such as PIC18F46K80), one end of the second communication circuit is connected to the first communication circuit, and the other end is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com