Hydraulic system of horizontal screw-discharging filter centrifuge and control method of hydraulic system

A hydraulic system, horizontal screw technology, applied in the hydraulic system and control field of horizontal screw discharge filter centrifuge, can solve the problem of large differential speed between the drum and the screw pusher, the differential speed cannot be accurately controlled, and the output torque is small and other problems, to achieve the effect of prolonging the residence time, saving energy and increasing torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

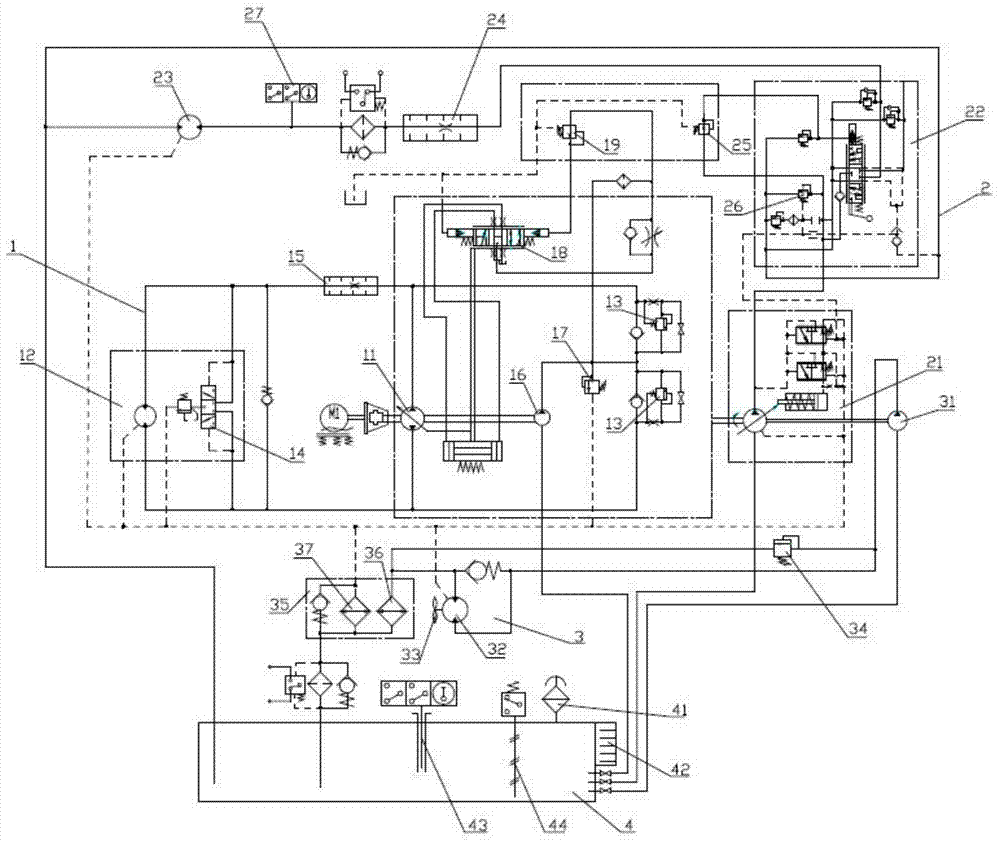

[0022] Such as figure 1 Shown: a hydraulic system of a horizontal screw discharge filter centrifuge, including a drum hydraulic system 1, a screw hydraulic system 2, a hydraulic cooling system 3 and a hydraulic oil tank 4, wherein the drum hydraulic system 1 includes a drum pump 11 , the drum motor 12, the drum pump 11 and the drum motor 12 form a closed circuit, and a pair of overflow valve groups 13, a flushing valve 14 and a first flow meter 15 are also arranged on the closed circuit, The overflow valve group 13 is used to control the pressure of the drum motor 12, the first flow meter 15 is used to monitor the flow of the drum pump 11 to the drum motor 12, and the drum hydraulic pressure The system 1 also includes a supplementary oil pump 16 and a supplementary oil relief valve 17. The supplementary oil pump 16 and the supplementary oil relief valve 17 form a supplementary oil system for supplying oil to the closed circuit, and also includes a three-position four through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com