Strong sound-absorbing part for traffic, its preparation method and application

A manufacturing method and sound absorption technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., to achieve the effect of quiet travel and riding environment, noise reduction, adverse effects and safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

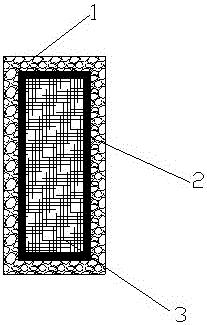

[0032] A strong sound-absorbing part for transportation, comprising: an expanded polytetrafluoroethylene film layer or an expanded polytetrafluoroethylene modified film layer 1, a bonding firm layer 2 and a sound-absorbing sheet layer 3, the bonding The firm layer 2 is a PU polyurethane adhesive bonding layer, and the method for preparing specifically comprises the following steps:

[0033] Material preparation of expanded polytetrafluoroethylene film layer or expanded polytetrafluoroethylene modified film layer 1 and sound-absorbing sheet layer 2, blanking, die-cutting of sound-absorbing sheet layer 3, expanded polytetrafluoroethylene The ethylene film layer or the expanded polytetrafluoroethylene modified film layer 1 is unwound on the coating machine, and then the expanded polytetrafluoroethylene film layer or the expanded polytetrafluoroethylene modified film layer 1 is coated with a roller of the coating machine Attaching the firm layer 2, the expanded polytetrafluoroethy...

Embodiment 2

[0035] A strong sound-absorbing part for transportation, comprising: an expanded polytetrafluoroethylene film layer or an expanded polytetrafluoroethylene modified film layer 1, a bonding firm layer 2 and a sound-absorbing sheet layer 3, the bonding The firm layer 2 is a hot-melt micropowder welding layer, and the method for preparation specifically includes the following steps:

[0036] Material preparation of expanded polytetrafluoroethylene film layer or expanded polytetrafluoroethylene modified film layer 1 and sound-absorbing sheet layer 3, blanking, die-cutting of sound-absorbing sheet layer 3, The fluoroethylene film layer or the expanded polytetrafluoroethylene modified film layer 1 is sprayed with a solid layer 2, and the expanded polytetrafluoroethylene film layer or the expanded polytetrafluoroethylene modified film layer 1 is combined with the die-cut molded The sound-absorbing sheet layer 3 is laminated and coated, the seams are heated and sealed, the rollers are ...

Embodiment 3

[0038] A strong sound-absorbing part for transportation, comprising: an expanded polytetrafluoroethylene film layer or an expanded polytetrafluoroethylene modified film layer 1, a bonding firm layer 2 and a sound-absorbing sheet layer 3, the bonding The firm layer 2 is welded with a low-density grammage non-woven fabric, and the preparation method specifically includes the following steps:

[0039]Material preparation of expanded polytetrafluoroethylene film layer or expanded polytetrafluoroethylene modified film layer 1 and sound-absorbing sheet layer 3, blanking, die-cutting of sound-absorbing sheet layer 3, The fluoroethylene film layer or the expanded polytetrafluoroethylene modified film layer 1 is laid with a bonding firm layer 2, and the expanded polytetrafluoroethylene film layer or the expanded polytetrafluoroethylene modified film layer 1 and the die-cut molded The sound-absorbing sheet layer 3 is laminated and coated, the seams are heated and sealed, the rollers are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com