Wiredrawing equipment and manufacture process of aluminum alloy drawing board

An aluminum alloy plate and aluminum alloy technology, which is applied in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve problems such as affecting the service life of handicrafts, discoloration and corrosion of the edges of attachments, and complex electroplating processing technology. Improve brightness and corrosion resistance, ease of operation, reduce energy consumption and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

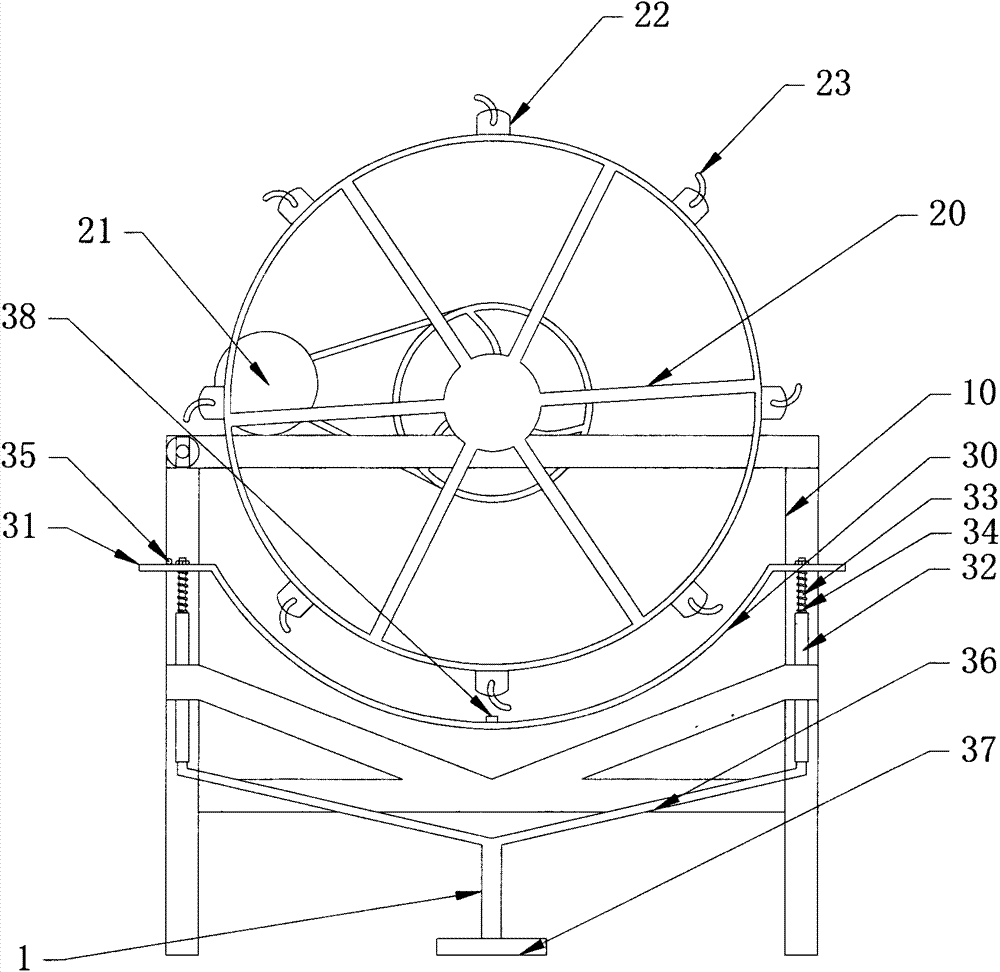

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] The aluminum alloy drawing board wire drawing equipment of the present invention comprises a frame 10, a wheel hub 20 and a motor 21, the wheel hub 20 is rotatably arranged on the beam of the frame 10, and the rotating shaft of the wheel hub 20 is connected to the motor 21 through transmission, and the wheel hub 20 There are several wire drawing cutter heads on the outer edge, and an arc-shaped brace 30 that matches the rotation track of the wire-drawing cutter is provided below the hub 20. The arc-shaped brace 30 of the present invention is preferably an arc-shaped steel strip, and the arc-shaped brace The diameter of the curvature of the plate 30 matches the diameter of the rotation track of the wire drawing cutter head, so that the hub 20 drives the wire drawing cutter head to rotate to make it cross the inner surface of the arc-shaped support plate 30; the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com