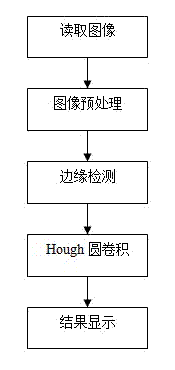

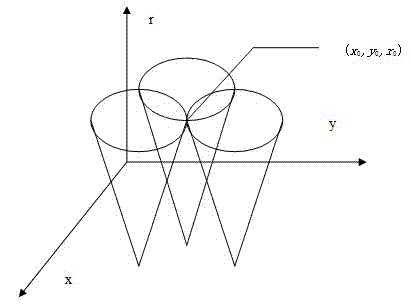

Hole set detection method and system based on Hough round convolution transformation algorithm

A technology for transforming algorithms and detection methods, which is applied in the direction of measuring devices, instruments, and optical devices, etc., which can solve the problems of high price, inability to detect the actual size and shape of the measured hole group, and high operating requirements of inspectors, and achieve real-time Good performance, improved automation production level, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions provided by the present invention will be described in detail below with reference to specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and not to limit the scope of the present invention.

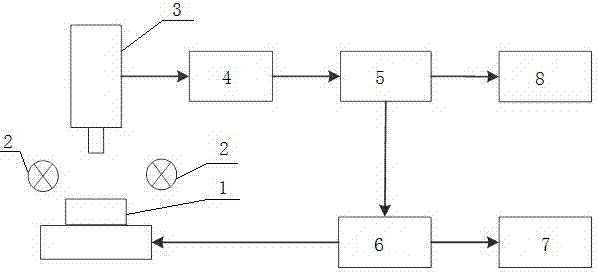

[0039] The present invention provides a complete set of hole group detection system, including workpiece to be tested 1 , image acquisition device, data processing device 5 , console 6 , alarm device 7 and database 8 . As shown in the figure, the image acquisition device includes a light source 2 , a camera 3 and an image acquisition card 4 . Obviously, the light source 2, the camera 3 and the image acquisition card 4 are only a possible solution to provide an image acquisition device, and those of ordinary skill in the art can also use other equipment or a combination of other equipment to realize the image of the workpiece to be measured. collection. figure 1 Among them, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com