Fixture system for creep test

A fixture system and creep test technology, which is applied in the field of creep test fixture systems, can solve problems such as damaged equipment, threats to the personal safety of operators, and experiments that cannot be carried out, and achieve lower requirements, strong practicability, and reduced tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

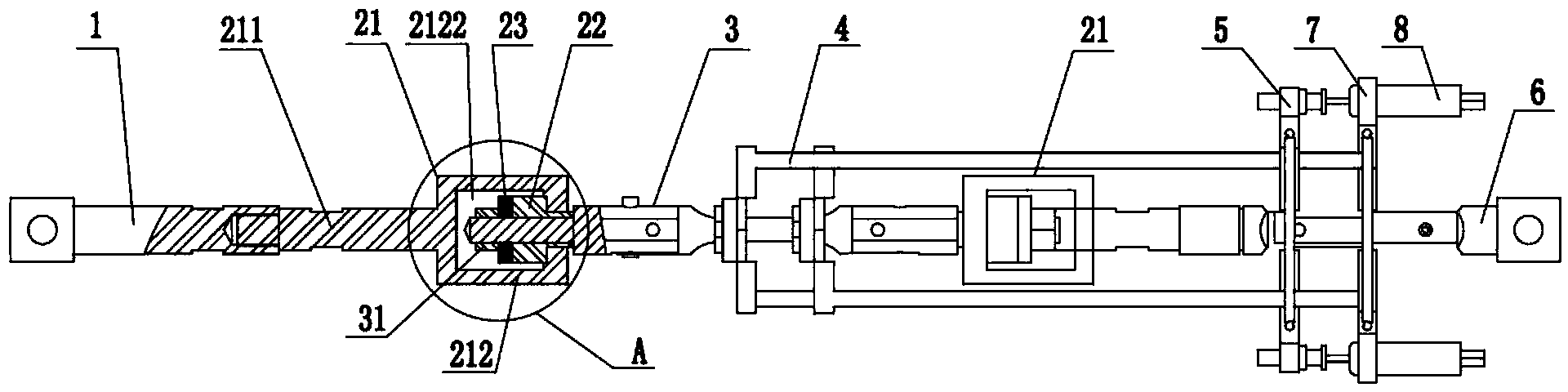

[0042] A fixture system for creep testing, see figure 1 , including an upper stretching rod 1 , a first connecting part, a second connecting part, a plate sample joint 3 , an extending rod 4 , an adjusting seat 5 and a lower stretching rod 6 .

[0043] The first connecting part includes a shoulder joint 21, a convex block 22 and a first gasket 23, and the overall structure is simplified.

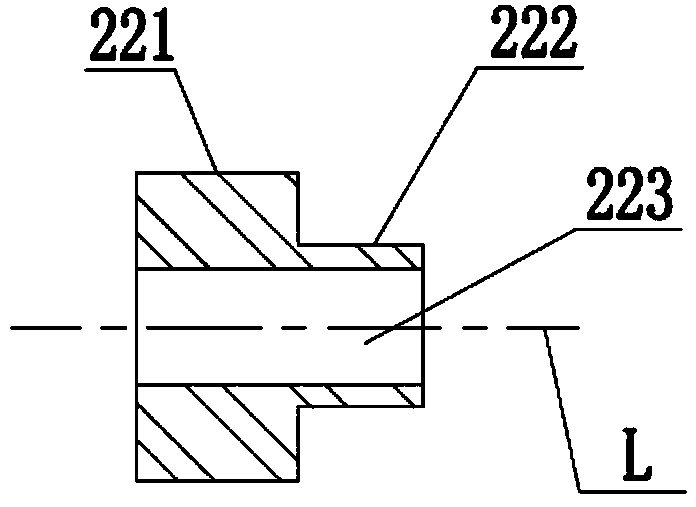

[0044] The convex block 22 includes a first end 221, a second end 222 and a first through hole 223, see figure 2 , on a plane perpendicular to the axis L thereof, the cross section of the first end 221 is larger than the cross section of the second end 222 , and the first through hole 223 is arranged along the axis L direction thereof.

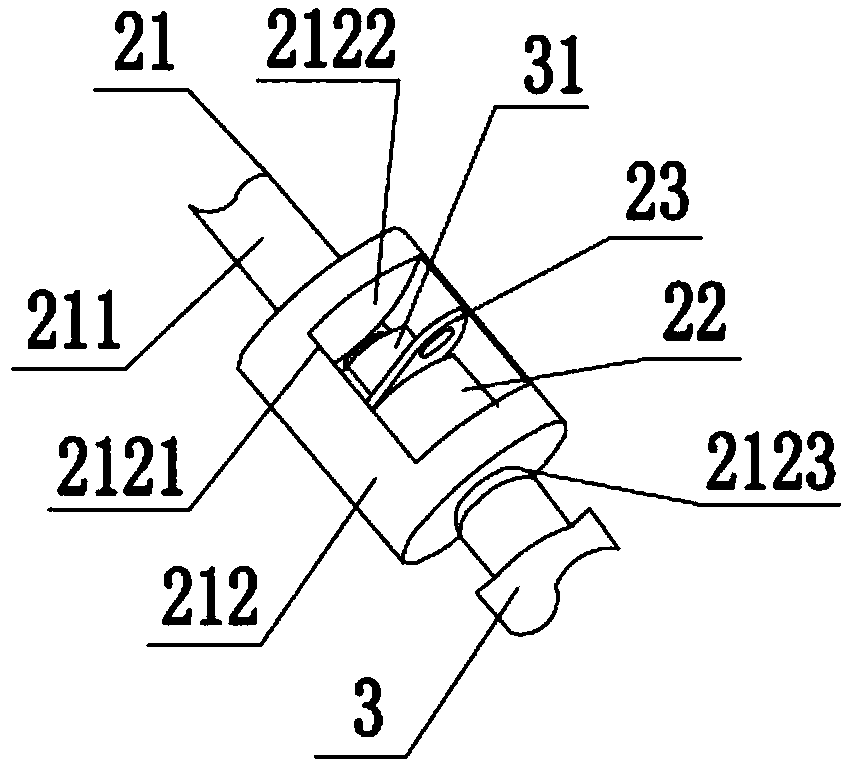

[0045] The shoulder joint 21 includes a connecting rod 211 and a frame body 212, see image 3 , the frame body 212 includes a cavity 2122 with an opening 2121, the front end of the connecting rod 211 is connected to the end of the upper stretch rod 1, and...

Embodiment 2

[0059] A clamp system for a creep test. Compared with Example 1, only the structures of the first connecting part and the second connecting part are different, and the first connecting part includes a first stopper 201, a second Stopper 202, second gasket 203, stretching block 204 and fixing part 205, see Image 6 as well as Figure 7 , the overall structure is simplified.

[0060] The first stopper 201, the second stopper 202, the second gasket 203 and the stretching block 204 are fixed by the fixing part 205, and the fixing part 205 adopts a combination of bolts and nuts adapted to each other, and is installed Convenience.

[0061] The first stopper 201 is arranged on the end surface of the end of the upper tensile rod 1 perpendicular to the axis of the upper stretching rod 1, and a third through hole is provided on it; the second stopper 202 is perpendicular to the plate sample The axis of the joint 3 is arranged on the end surface of its front end, and a fourth through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com