Electronic paper display device

A display device, electronic paper technology, applied in the direction of instruments, optical components, optics, etc., can solve the problems of uneven color rendering, bright color, unstable dyeing of charged particles, etc., and achieve high practicability and generalizability, pure color Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

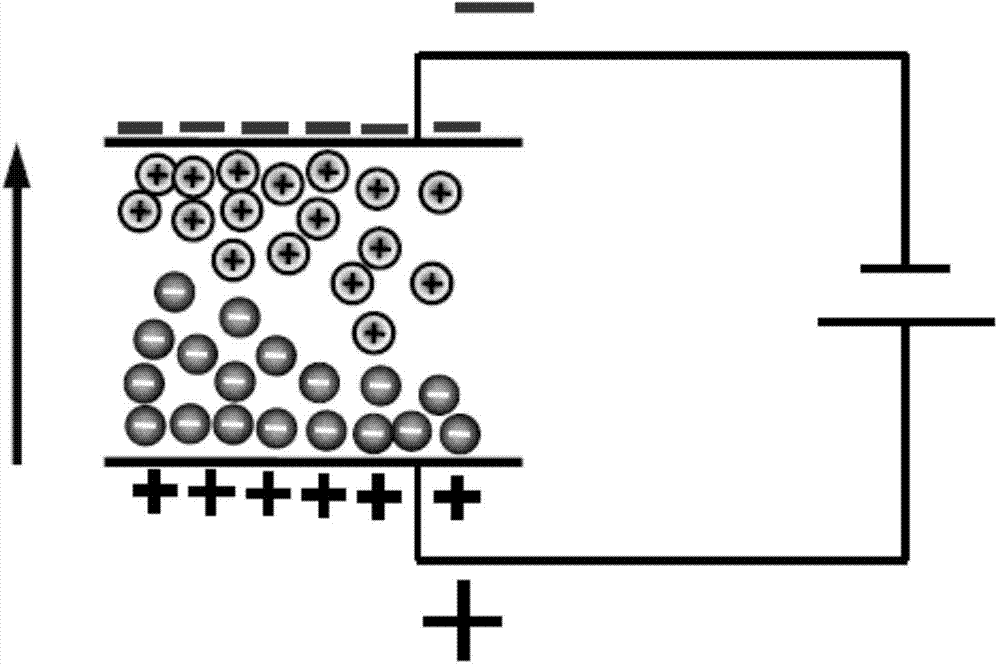

[0047] This solution includes but is not limited to the following embodiments: (1) The charged particles in the microcapsules of the present invention are composed of positively charged white particles and negatively charged black particles coated with a quantum dot layer, wherein the quantum dots The quantum dots in the dot layer are not charged. In this solution, the particle size of the quantum dots can be selected from one of the quantum dots used to display red, green and blue (18-20nm, 12-14nm and 6-8nm). When it is necessary to display black, control the voltage of the upper electrode to be greater than the voltage of the lower electrode, then it is a black picture from above. When wanting to display color patterns, control the voltage of the upper electrode to be lower than the voltage of the lower electrode, and at this time, the positively charged electron points move upward to the upper electrode. When external light is incident, the quantum dots are excited to emi...

Embodiment 1

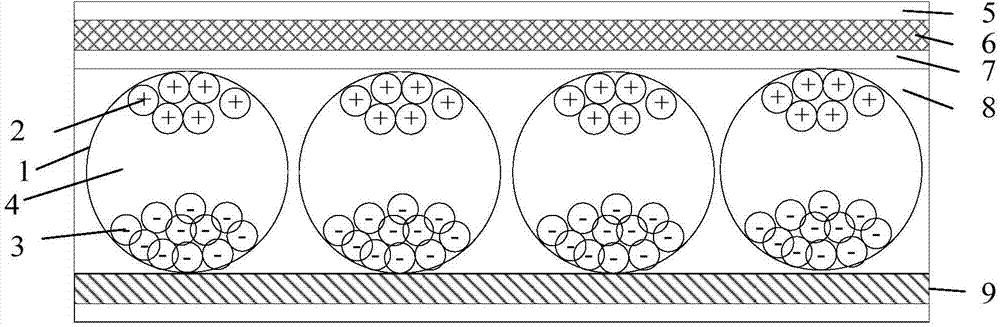

[0065] Such as figure 2 The film layer structure of the electrophoretic display (EPD) shown: from top to bottom, it includes protective film 5, organic plastic 6, ITO7, adhesive layer 8; adhesive layer 9 and pixel electrodes (not marked in the figure), in Microcapsules 1 are arranged in the adhesive layer 8 (between the two layers of electrodes).

[0066] Such as Figure 4 As shown, in this embodiment, the microcapsule 1 includes positively charged white particles 2 and negatively charged black particles 3, wherein the positively charged white particles 2 are coated with blue quantum dots 13. point layer.

[0067] When it is necessary to display black, control the voltage of the upper electrode to be greater than the voltage of the lower electrode, then it is a black picture from above. When wanting to display a blue pattern, control the voltage of the upper electrode to be lower than the voltage of the lower electrode, and at this time, the positively charged white partic...

Embodiment 2

[0070] Compared with embodiment 1, the difference is only in:

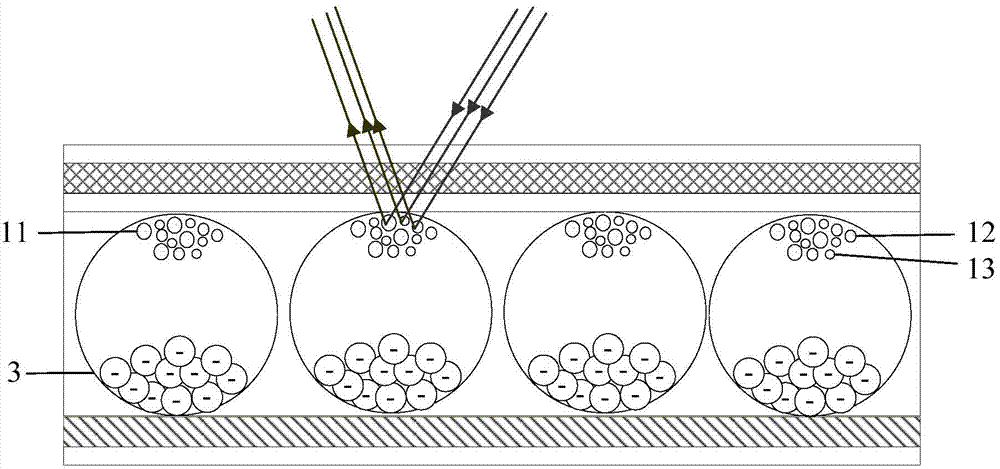

[0071] Such as Figure 5 As shown, in this embodiment, the microcapsule 1 includes positively charged white particles 2 and negatively charged black particles 3, wherein the negatively charged black particles 3 are coated with quantum dots composed of blue quantum dots 13 Floor.

[0072] When it is necessary to display blue, the voltage of the upper electrode is controlled to be greater than the voltage of the lower electrode, and when external light is incident, the quantum dots are excited to emit blue light to complete the blue display. When wanting to display a white pattern, the voltage of the upper electrode is controlled to be lower than the voltage of the lower electrode. At this time, the positively charged white particles 2 move upward to the upper electrode to complete white display.

[0073] In this embodiment, when the quantum dot layers are all made of 18-20nm quantum dots, this solution can realiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com