A Method to Eliminate the Five-Axis Singularity Problem in the Path Planning Stage

A path planning, singular technology, applied in the direction of electrical program control, digital control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

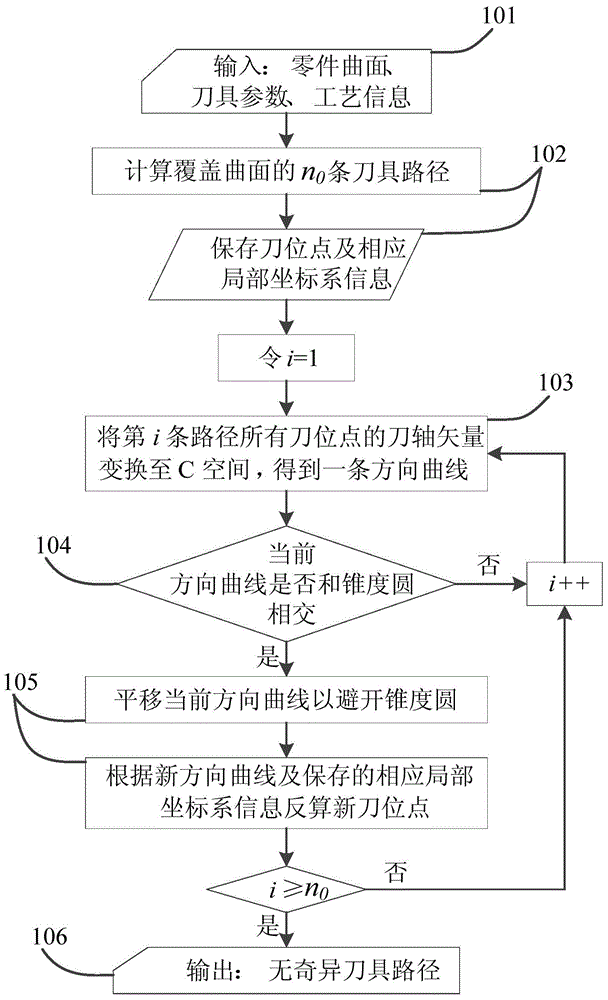

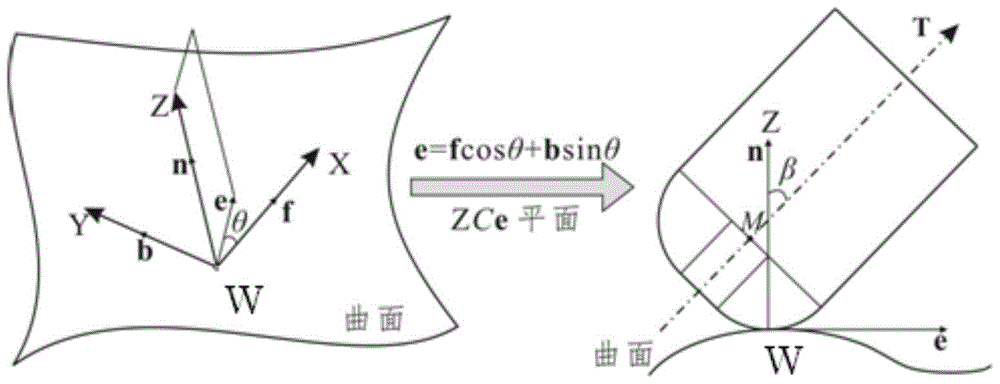

Method used

Image

Examples

Embodiment

[0082] A typical implementation example of the present invention is as follows:

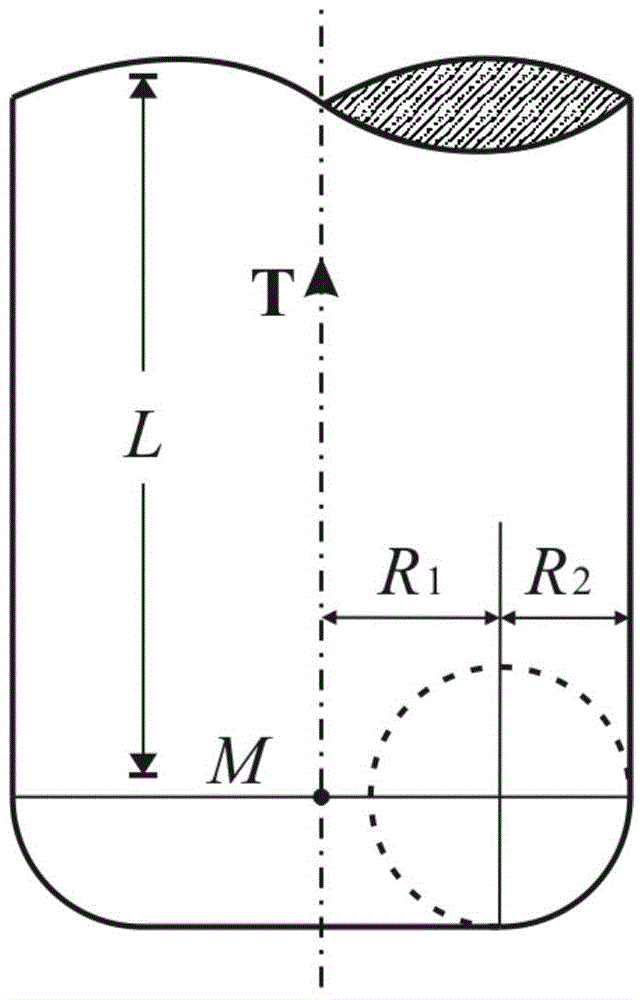

[0083] 1. The surface of the part to be processed selected in this example is a 3-degree B-spline surface, such as Figure 8 shown. The surface size is about 100×100mm 2 , which is special in that it is raised around and sunken in the middle. When the tool runs from the depression 801 (convex) to the projection 802 (concave) along the tool path on the curved surface, there is a high probability of encountering singularity problems. The parameters of the selected ring knife are: bottom surface radius R 1 =2mm, fillet radius R 2 =1mm, the handle length L=15mm.

[0084] 2. The conventional tool path generation method selected is the equal parameter method. First, 200 isoparametric curves are selected on the above surface as path curves, and 200 tool contacts are sequentially selected on each path curve to calculate the corresponding tool position points, and the local coordinate system informa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com