Method for optimizing gas-solid two-phase flow field and ammonia spraying of selective catalytic reduction denitration device

An optimization method and selective technology, applied in chemical instruments and methods, separation methods, instruments, etc., can solve the problems of high ammonia escape rate, catalyst wear and fouling, low denitration efficiency, etc., to improve denitration efficiency and prolong service life. , Reduce the effect of catalyst fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

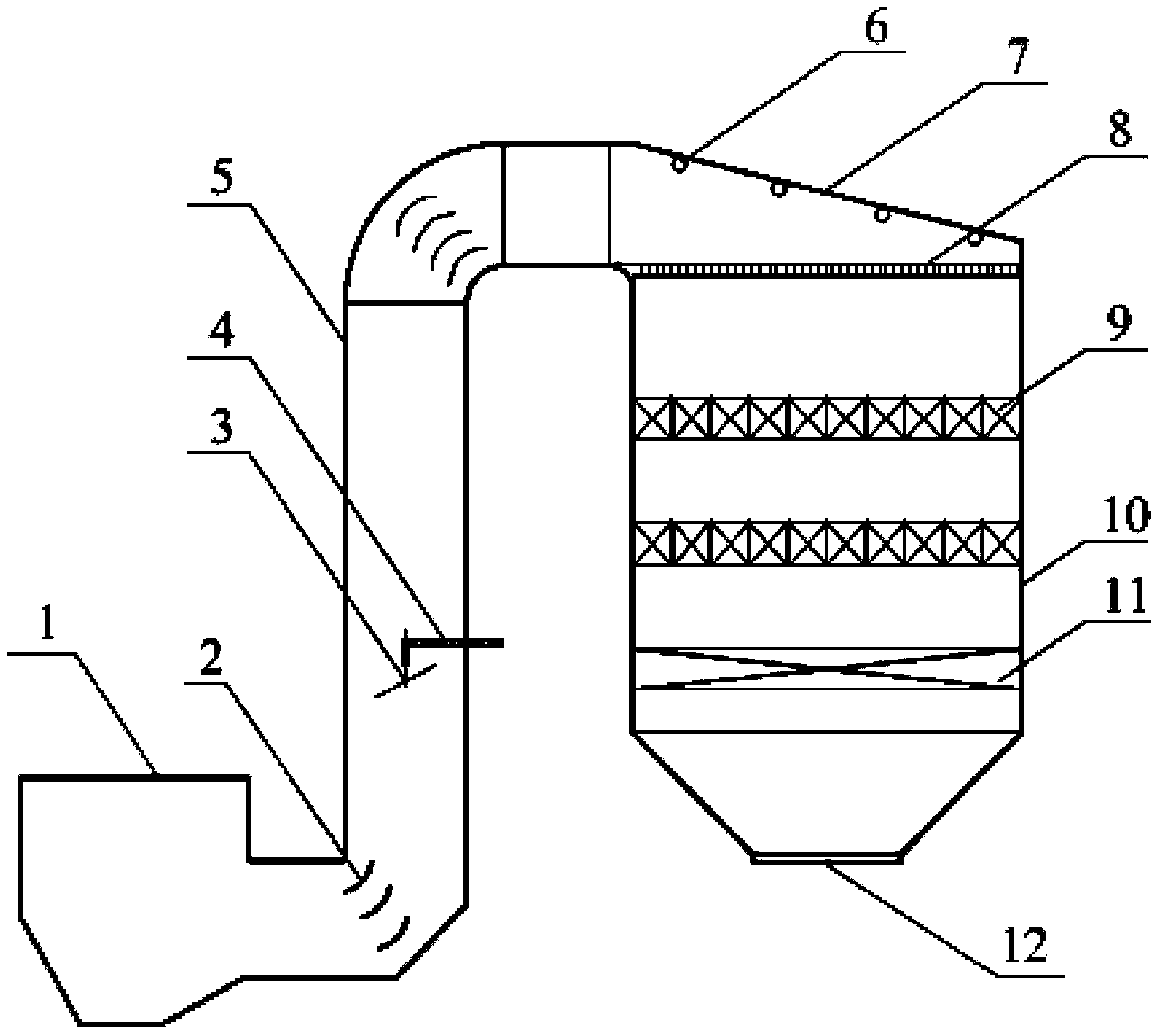

[0019] The present invention provides a gas-solid two-phase flow field and ammonia injection control optimization method for an SCR denitrification device based on non-uniform inlet conditions. The steps of the method are as follows:

[0020] (1) According to the structure and size of the actual operating SCR denitrification device, use Gambit software to establish a three-dimensional physical model including the connecting flue and SCR reactor;

[0021] (2) Obtain the non-uniformity conditions at the inlet of the SCR denitrification device by means of experiments, numerical simulations or field tests (including the velocity distribution, temperature distribution, component concentration distribution of the flue gas on the inlet section and the concentration distribution of fly ash particles, particle size diameter distribution, etc.), and use this condition as the inlet boundary condition of the calculation model;

[0022] (3) Use Fluent software to simulate the gas-solid two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com