Optimum layout of power battery electrodes and ultrasonic welding method and device

A technology for ultrasonic welding and power batteries, which is applied in welding equipment, non-electric welding equipment, battery pack components, etc., can solve problems such as explosion, battery heating, and aggravated thermal effects, so as to improve safety, reduce internal resistance, and increase overheating. flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

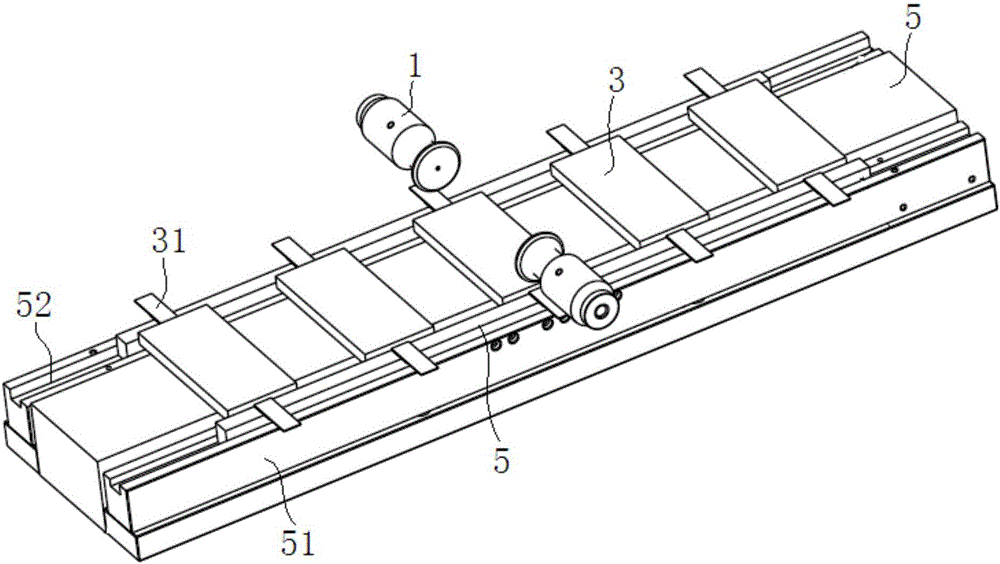

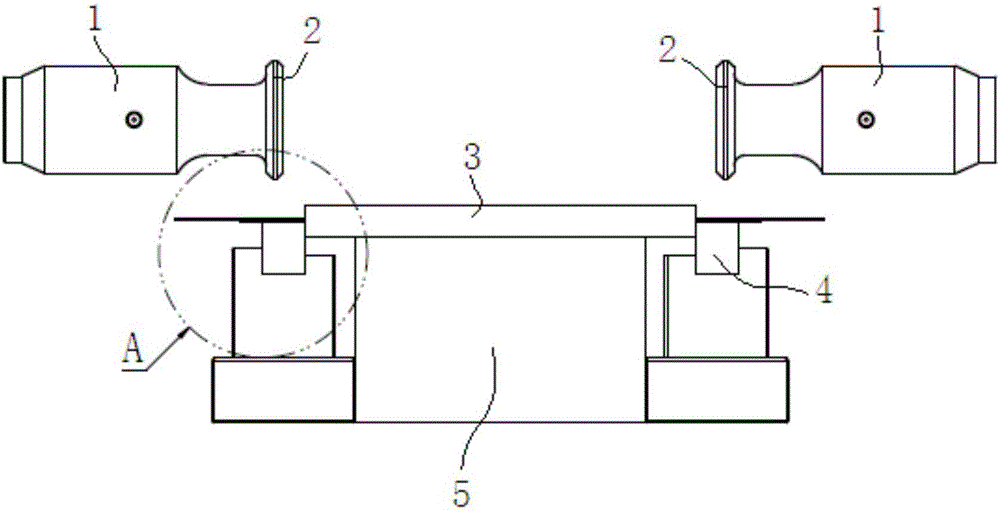

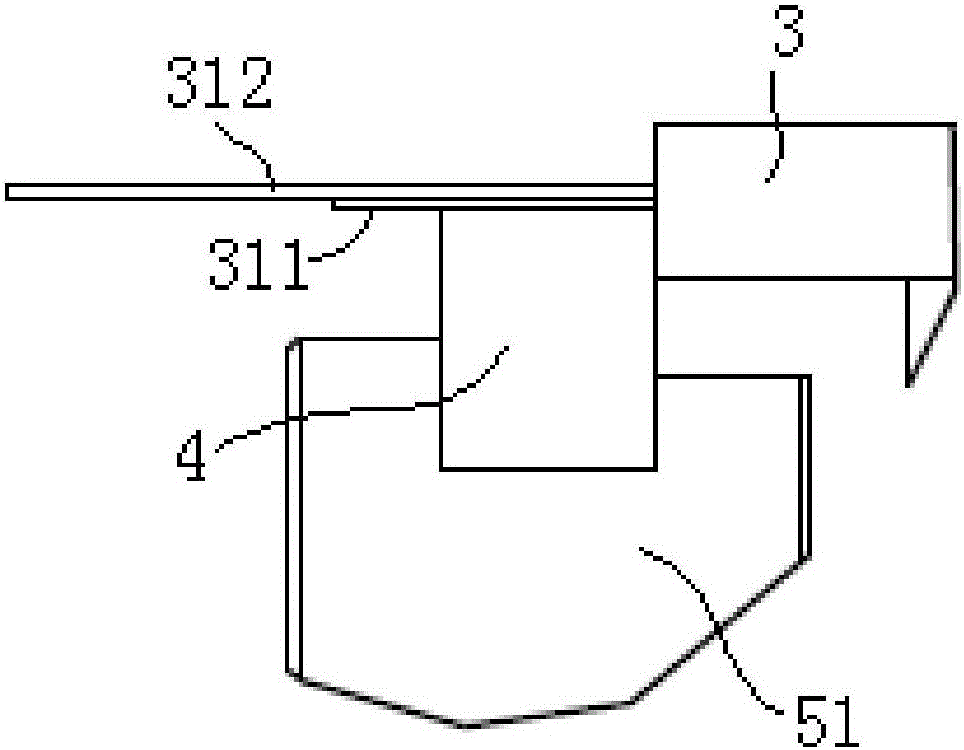

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0042] Optimized layout of power battery electrodes, such as Figure 8-10 As shown, in the single battery, the lead-out positions of the positive electrode and the negative electrode are set in the opposite direction of the maximum distance. The positive electrode and the negative electrode may be respectively located on both sides of the single battery with the largest distance. In this way, when the battery is working, the electrons flow in the distance between the two opposite ends, and the widest channel flow given by the effective cross-sectional area of the space in the battery can be fully utilized to fully mobilize the best flow of electrons in the battery. Conditions, so that the internal resistance of the running channel is the smallest, so that the thermal effect of the battery can be minimized and heat generation can be avoided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com