A litchi drying method that can improve the immunomodulatory activity of pulp polysaccharides

An immunomodulatory activity and drying method technology, applied in the field of fruit drying, can solve the problems of high energy consumption, high production cost, expensive equipment, etc., and achieve the effects of preventing browning, strengthening immunomodulatory activity, and improving immunomodulatory activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

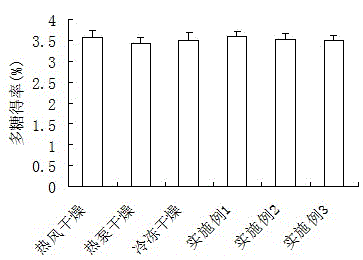

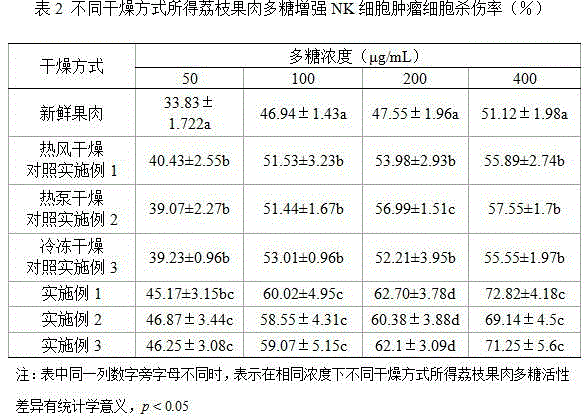

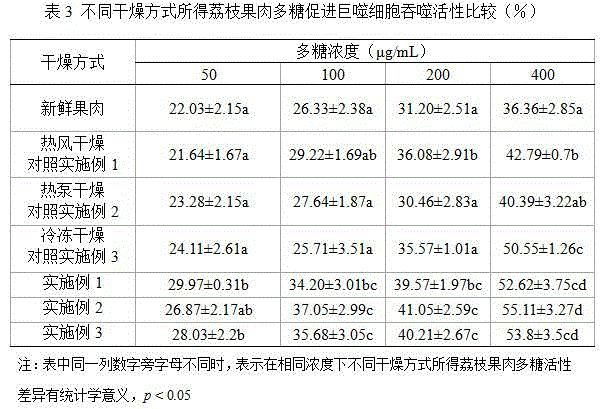

Examples

Embodiment 1

[0017] (1) Select lychees that are free from diseases and insect pests, intact and without cracks, and after cleaning, drain the water on the stainless steel grid.

[0018] (2) Send the drained lychees to the hot air drying equipment for 4 h at 92 °C.

[0019] (3) Turn on the heat pump drying device, keep the temperature in the machine cavity at 55 °C, and the wind speed at 1 m / s, transfer the lychee after greening to the heat pump drying system, and start the heat pump drying process.

[0020] (4) The heat pump drying adopts the intermittent drying mode in which the drying system is turned off for 4 h after drying for 12 h, and the drying-slow cycle is repeated for a total of 3 times to obtain dried litchi fruits.

Embodiment 2

[0022] (1) Select lychees that are free from diseases and insect pests, intact and without cracks, and after cleaning, drain the water on the stainless steel grid.

[0023] (2) Send the drained lychees to the hot air drying equipment for 6 hours at 86°C.

[0024] (3) Turn on the heat pump drying device, keep the temperature in the machine cavity at 50°C, and the wind speed at 1 m / s, transfer the dried lychees to the heat pump drying system, and start the heat pump drying process.

[0025] (4) The heat pump drying adopts the intermittent drying mode in which the drying system is turned off for 3 h after drying for 12 h, and the drying-slow cycle is repeated for a total of 3 times to obtain dried litchi fruits.

Embodiment 3

[0027] (1) Select lychees that are free from diseases and insect pests, intact and without cracks, and after cleaning, drain the water on the stainless steel grid.

[0028] (2) Send the drained lychee into hot air drying equipment for 5 hours at 90°C.

[0029] (3) Turn on the heat pump drying device, keep the temperature in the machine cavity at 55°C, and the wind speed at 1 m / s, transfer the lychee after greening to the heat pump drying system, and start the heat pump drying process.

[0030] (4) The heat pump drying adopts the intermittent drying mode in which the drying system is turned off for 4 h after drying for 10 h, and the drying-slow cycle is repeated for a total of 3 times to obtain dried litchi fruits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com