A kind of distiller's grain cottonseed meal soluble protein powder and preparation method thereof

A cottonseed meal, soluble technology, applied in the direction of protein food processing, plant protein processing, protein food ingredients, etc., can solve the problems of insufficient protein source, adverse effects on growth, development and reproduction, and can not be fully utilized, etc., to achieve the goal of improving nutritional value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

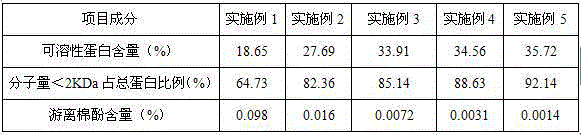

Examples

Embodiment 1

[0066] Embodiment 1: (without adding distiller's grains)

[0067] A soluble protein powder of distiller's grain cottonseed meal, which is made of the following raw materials in parts by weight (optimal value):

[0068] Raw material parts by weight

[0069] Cottonseed Meal 100

[0070] water 250

[0071] Ferrous sulfate (food grade) 1

[0072] Calcium hydroxide (food grade) 1.5

[0073] Alkaline protease 3

[0074] Compound Flavor Protease 2.9. (alkaline endoprotease 200,000 u / g, flavor protease 200,000 u / g)

[0075] A method for preparing distiller's grains cottonseed meal soluble protein powder, the preparation steps are:

[0076] (1) Mix cottonseed meal, ferrous sulfate and calcium hydroxide evenly, add water at a mass ratio of 0.8-1:1, soak for 28 or 29 or 30 or 31 or 32 minutes, and fumigate at 121°C and 0.14-0.18Mpa for 1.0 Or 2.0h, so that the cottonseed meal can be well detoxified.

[0077] (2) The fumigated cottonseed meal is refined with water at a mass ratio ...

Embodiment 2

[0081] Stir and mix 100g cottonseed meal, 60g distiller's grains, 1.0g ferrous sulfate, and 1.5g calcium hydroxide, add 240g water for refining, adjust the pH value of the mixed slurry to 8.0, 3.0g alkaline protease, and enzymatically hydrolyze 5.0 at 60°C h; then adjust the temperature of the slurry to 55°C, adjust the pH value to 7.0, add 2.0g of compound flavor protease, enzymatically hydrolyze at 55°C for 3.0h, and inactivate the enzyme at 85°C to obtain the enzymatic hydrolyzate, which is then spray-dried to obtain distiller's grains cottonseed Meal soluble protein powder.

[0082] Other implementation steps are the same as in Example 1.

Embodiment

[0084] Stir and mix 100g cottonseed meal, 60g distiller's grains, 1.0g ferrous sulfate, and 1.5g calcium hydroxide, add 150g water, soak for 30min, fumigate at 121°C and 0.15Mpa for 1.0h, add 160g water for refining, and adjust the mixing The pH value of the slurry is 8.0, 3.0g alkaline protease, 60°C enzymolysis for 5.0h; then adjust the temperature of the slurry to 55°C, adjust the pH value to 7.0, add 2.0g compound flavor protease, 55°C enzymolysis for 3.0h, After the enzyme is extinguished at 85°C, the enzymatic solution is obtained, which is spray-dried to obtain the soluble protein powder of distiller's grain cottonseed meal.

[0085] Other implementation steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com